Manuale Officina LGW 523-627 - lombardini service

Manuale Officina LGW 523-627 - lombardini service

Manuale Officina LGW 523-627 - lombardini service

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

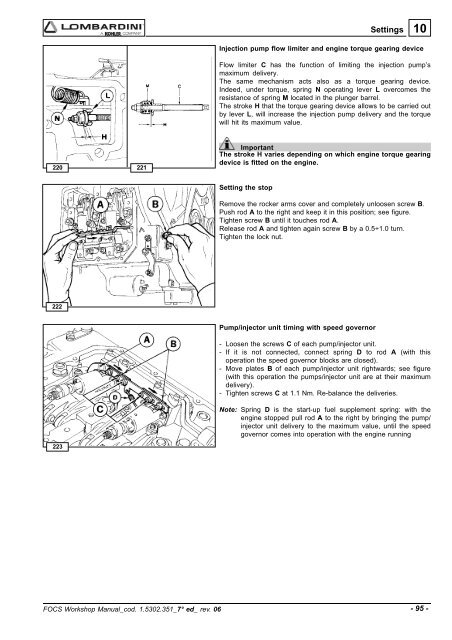

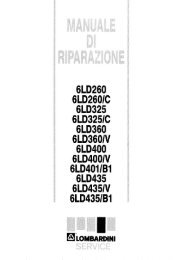

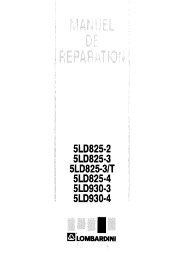

Settings10Injection pump flow limiter and engine torque gearing deviceFlow limiter C has the function of limiting the injection pump’smaximum delivery.The same mechanism acts also as a torque gearing device.Indeed, under torque, spring N operating lever L overcomes theresistance of spring M located in the plunger barrel.The stroke H that the torque gearing device allows to be carried outby lever L, will increase the injection pump delivery and the torquewill hit its maximum value.220 221ImportantThe stroke H varies depending on which engine torque gearingdevice is fitted on the engine.Setting the stopRemove the rocker arms cover and completely unloosen screw B.Push rod A to the right and keep it in this position; see figure.Tighten screw B until it touches rod A.Release rod A and tighten again screw B by a 0.5÷1.0 turn.Tighten the lock nut.222Pump/injector unit timing with speed governor- Loosen the screws C of each pump/injector unit.- If it is not connected, connect spring D to rod A (with thisoperation the speed governor blocks are closed).- Move plates B of each pump/injector unit rightwards; see figure(with this operation the pumps/injector unit are at their maximumdelivery).- Tighten screws C at 1.1 Nm. Re-balance the deliveries.Note: Spring D is the start-up fuel supplement spring: with theengine stopped pull rod A to the right by bringing the pump/injector unit delivery to the maximum value, until the speedgovernor comes into operation with the engine running223FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06- 95 -