Manuale Officina LGW 523-627 - lombardini service

Manuale Officina LGW 523-627 - lombardini service

Manuale Officina LGW 523-627 - lombardini service

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

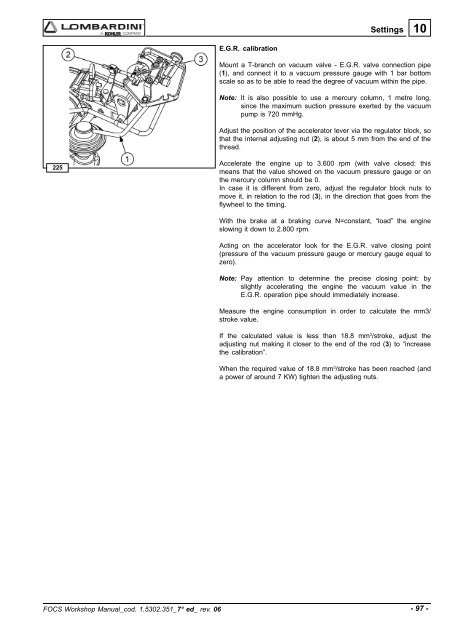

Settings10E.G.R. calibrationMount a T-branch on vacuum valve - E.G.R. valve connection pipe(1), and connect it to a vacuum pressure gauge with 1 bar bottomscale so as to be able to read the degree of vacuum within the pipe.Note: It is also possible to use a mercury column, 1 metre long,since the maximum suction pressure exerted by the vacuumpump is 720 mmHg.Adjust the position of the accelerator lever via the regulator block, sothat the internal adjusting nut (2), is about 5 mm from the end of thethread.225Accelerate the engine up to 3.600 rpm (with valve closed: thismeans that the value showed on the vacuum pressure gauge or onthe mercury column should be 0.In case it is different from zero, adjust the regulator block nuts tomove it, in relation to the rod (3), in the direction that goes from theflywheel to the timing.With the brake at a braking curve N=constant, “load” the engineslowing it down to 2.800 rpm.Acting on the accelerator look for the E.G.R. valve closing point(pressure of the vacuum pressure gauge or mercury gauge equal tozero).Note: Pay attention to determine the precise closing point: byslightly accelerating the engine the vacuum value in theE.G.R. operation pipe should immediately increase.Measure the engine consumption in order to calculate the mm3/stroke value.If the calculated value is less than 18.8 mm 3 /stroke, adjust theadjusting nut making it closer to the end of the rod (3) to “increasethe calibration”.When the required value of 18.8 mm 3 /stroke has been reached (anda power of around 7 KW) tighten the adjusting nuts.FOCS Workshop Manual_cod. 1.5302.351_7° ed_ rev. 06- 97 -