1900 Series - Maintenance Manual

1900 Series - Maintenance Manual

1900 Series - Maintenance Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

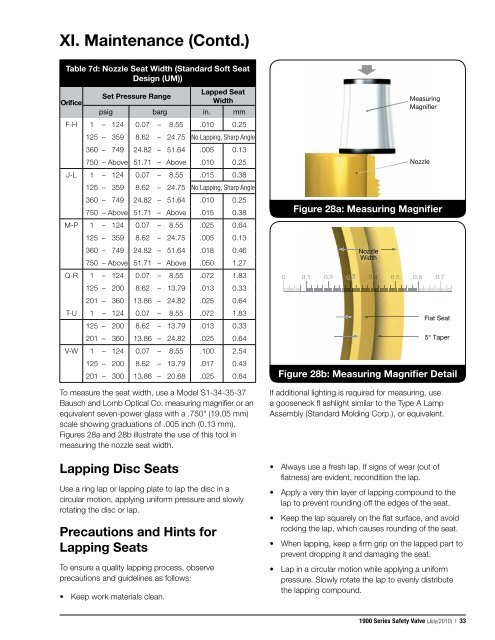

XI. <strong>Maintenance</strong> (Contd.)Table 7d: Nozzle Seat Width (Standard Soft SeatDesign (UM))OrificeLapped SeatSet Pressure RangeWidthpsig barg in. mmF-H 1 – 124 0.07 – 8.55 .010 0.25125 – 359 8.62 – 24.75 No Lapping, Sharp Angle360 – 749 24.82 – 51.64 .005 0.13750 – Above 51.71 – Above .010 0.25J-L 1 – 124 0.07 – 8.55 .015 0.38125 – 359 8.62 – 24.75 No Lapping, Sharp Angle360 – 749 24.82 – 51.64 .010 0.25750 – Above 51.71 – Above .015 0.38M-P 1 – 124 0.07 – 8.55 .025 0.64125 – 359 8.62 – 24.75 .005 0.13360 – 749 24.82 – 51.64 .018 0.46750 – Above 51.71 – Above .050 1.27Q-R 1 – 124 0.07 – 8.55 .072 1.83125 – 200 8.62 – 13.79 .013 0.33201 – 360 13.86 – 24.82 .025 0.64T-U 1 – 124 0.07 – 8.55 .072 1.83125 – 200 8.62 – 13.79 .013 0.33201 – 360 13.86 – 24.82 .025 0.64V-W 1 – 124 0.07 – 8.55 .100 2.54125 – 200 8.62 – 13.79 .017 0.43201 – 300 13.86 – 20.68 .025 0.64To measure the seat width, use a Model S1-34-35-37Bausch and Lomb Optical Co. measuring magnifier or anequivalent seven-power glass with a .750" (19.05 mm)scale showing graduations of .005 inch (0.13 mm).Figures 28a and 28b illustrate the use of this tool inmeasuring the nozzle seat width.Lapping Disc SeatsUse a ring lap or lapping plate to lap the disc in acircular motion, applying uniform pressure and slowlyrotating the disc or lap.Precautions and Hints forLapping SeatsTo ensure a quality lapping process, observeprecautions and guidelines as follows:• Keep work materials clean.0NozzleWidthMeasuringMagnifierNozzleFigure 28a: Measuring Magnifier0.10.20.3 0 30.40.5 0. 6 0.7Flat Seat5° TaperFigure 28b: Measuring Magnifier DetailIf additional lighting is required for measuring, usea gooseneck fl ashlight similar to the Type A LampAssembly (Standard Molding Corp.), or equivalent.• Always use a fresh lap. If signs of wear (out offlatness) are evident, recondition the lap.• Apply a very thin layer of lapping compound to thelap to prevent rounding off the edges of the seat.• Keep the lap squarely on the flat surface, and avoidrocking the lap, which causes rounding of the seat.• When lapping, keep a firm grip on the lapped part toprevent dropping it and damaging the seat.• Lap in a circular motion while applying a uniformpressure. Slowly rotate the lap to evenly distributethe lapping compound.<strong>1900</strong> <strong>Series</strong> Safety Valve (July/2010) | 33