1900 Series - Maintenance Manual

1900 Series - Maintenance Manual

1900 Series - Maintenance Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

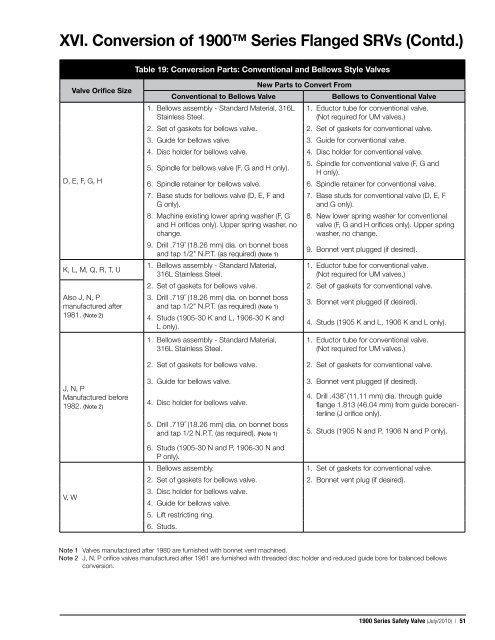

XVI. Conversion of <strong>1900</strong> <strong>Series</strong> Flanged SRVs (Contd.)Table 19: Conversion Parts: Conventional and Bellows Style ValvesValve Orifice SizeD, E, F, G, HK, L, M, Q, R, T, UAlso J, N, Pmanufactured after1981. (Note 2)New Parts to Convert FromConventional to Bellows ValveBellows to Conventional Valve1. Bellows assembly - Standard Material, 316L 1. Eductor tube for conventional valve.Stainless Steel.(Not required for UM valves.)2. Set of gaskets for bellows valve. 2. Set of gaskets for conventional valve.3. Guide for bellows valve. 3. Guide for conventional valve.4. Disc holder for bellows valve. 4. Disc holder for conventional valve.5. Spindle for bellows valve (F, G and H only).5. Spindle for conventional valve (F, G andH only).6. Spindle retainer for bellows valve. 6. Spindle retainer for conventional valve.7. Base studs for bellows valve (D, E, F andG only).8. Machine existing lower spring washer (F, Gand H orifices only). Upper spring washer, nochange.9. Drill .719˝ (18.26 mm) dia. on bonnet bossand tap 1/2" N.P.T. (as required) (Note 1)1. Bellows assembly - Standard Material,316L Stainless Steel.7. Base studs for conventional valve (D, E, Fand G only).8. New lower spring washer for conventionalvalve (F, G and H orifices only). Upper springwasher, no change.9. Bonnet vent plugged (if desired).1. Eductor tube for conventional valve.(Not required for UM valves.)2. Set of gaskets for bellows valve. 2. Set of gaskets for conventional valve.3. Drill .719˝ (18.26 mm) dia. on bonnet bossand tap 1/2" N.P.T. (as required) (Note 1)3. Bonnet vent plugged (if desired).4. Studs (1905-30 K and L, 1906-30 K andL only).4. Studs (1905 K and L, 1906 K and L only).1. Bellows assembly - Standard Material,316L Stainless Steel.1. Eductor tube for conventional valve.(Not required for UM valves.)2. Set of gaskets for bellows valve. 2. Set of gaskets for conventional valve.J, N, PManufactured before1982. (Note 2)V, W3. Guide for bellows valve. 3. Bonnet vent plugged (if desired).4. Disc holder for bellows valve.5. Drill .719˝ (18.26 mm) dia. on bonnet bossand tap 1/2 N.P.T. (as required). (Note 1)4. Drill .438˝ (11.11 mm) dia. through guideflange 1.813 (46.04 mm) from guide borecenterline(J orifice only).5. Studs (1905 N and P, 1906 N and P only).6. Studs (1905-30 N and P, 1906-30 N andP only).1. Bellows assembly. 1. Set of gaskets for conventional valve.2. Set of gaskets for bellows valve. 2. Bonnet vent plug (if desired).3. Disc holder for bellows valve.4. Guide for bellows valve.5. Lift restricting ring.6. Studs.Note 1 Valves manufactured after 1980 are furnished with bonnet vent machined.Note 2 J, N, P orifice valves manufactured after 1981 are furnished with threaded disc holder and reduced guide bore for balanced bellowsconversion.<strong>1900</strong> <strong>Series</strong> Safety Valve (July/2010) | 51