309244D 50:1 Ratio Double Acting Falcon Grease Pumps - Graco Inc.

309244D 50:1 Ratio Double Acting Falcon Grease Pumps - Graco Inc.

309244D 50:1 Ratio Double Acting Falcon Grease Pumps - Graco Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

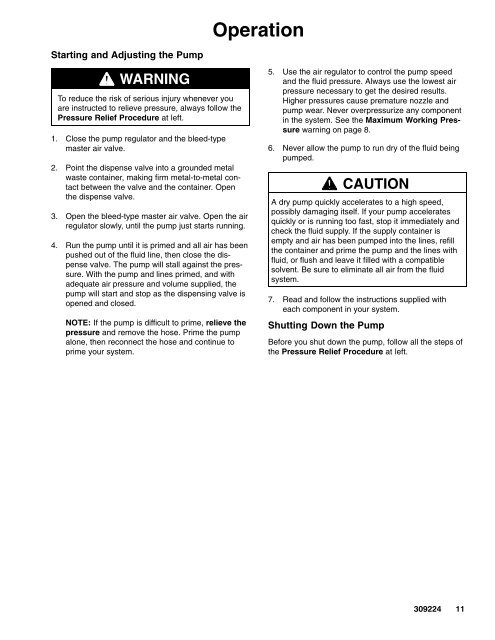

OperationStarting and Adjusting the PumpWARNINGTo reduce the risk of serious injury whenever youare instructed to relieve pressure, always follow thePressure Relief Procedure at left.1. Close the pump regulator and the bleed-typemaster air valve.2. Point the dispense valve into a grounded metalwaste container, making firm metal-to-metal contactbetween the valve and the container. Openthe dispense valve.3. Open the bleed-type master air valve. Open the airregulator slowly, until the pump just starts running.4. Run the pump until it is primed and all air has beenpushed out of the fluid line, then close the dispensevalve. The pump will stall against the pressure.With the pump and lines primed, and withadequate air pressure and volume supplied, thepump will start and stop as the dispensing valve isopened and closed.NOTE: If the pump is difficult to prime, relieve thepressure and remove the hose. Prime the pumpalone, then reconnect the hose and continue toprime your system.5. Use the air regulator to control the pump speedand the fluid pressure. Always use the lowest airpressure necessary to get the desired results.Higher pressures cause premature nozzle andpump wear. Never overpressurize any componentin the system. See the Maximum Working Pressurewarning on page 8.6. Never allow the pump to run dry of the fluid beingpumped.CAUTIONA dry pump quickly accelerates to a high speed,possibly damaging itself. If your pump acceleratesquickly or is running too fast, stop it immediately andcheck the fluid supply. If the supply container isempty and air has been pumped into the lines, refillthe container and prime the pump and the lines withfluid, or flush and leave it filled with a compatiblesolvent. Be sure to eliminate all air from the fluidsystem.7. Read and follow the instructions supplied witheach component in your system.Shutting Down the PumpBefore you shut down the pump, follow all the steps ofthe Pressure Relief Procedure at left.