Texture Sprayers Electrical & Mechinical Troubleshooting Manual

Texture Sprayers Electrical & Mechinical Troubleshooting Manual

Texture Sprayers Electrical & Mechinical Troubleshooting Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

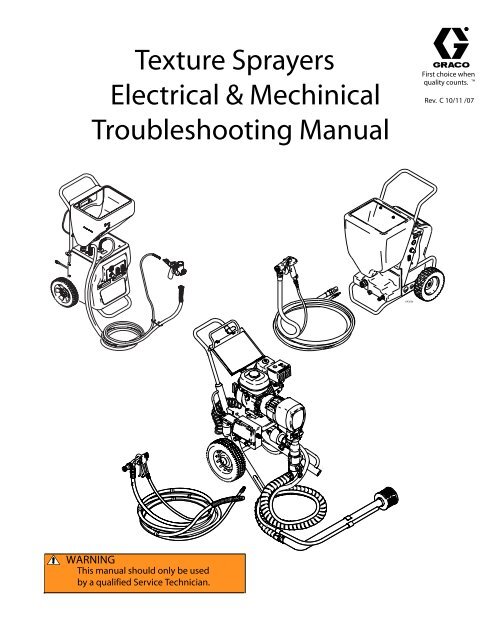

<strong>Texture</strong> <strong>Sprayers</strong><strong>Electrical</strong> & <strong>Mechinical</strong><strong>Troubleshooting</strong> <strong>Manual</strong>First choice whenquality counts.Rev. C 10/11 /07ti4305aWARNINGThis manual should only be usedby a qualified Service Technician.

Table of ContentsBasic meter terminology and testing procedures................................................................................................. 3-9Electric <strong>Texture</strong> <strong>Sprayers</strong>RTX 650 and TX 65:• Motor will not start.................................................................................................................................. 10RTX 900,1250 and TX 90,125:• Motor will not start.................................................................................................................................. 11RTX 750 and RTX 1000:• Motors will not start ........................................................................................................................... 12,13• RotoFlex Motor will not start .................................................................................................................. 14• Air Compressor Motor will not start ....................................................................................................... 15RTX 1500:Operational and troubleshooting:• Power cord plugged in and Power Switch Off ....................................................................................... 16• Power cord plugged in and Power Switch ON ........................................................................................ 17• Power cord plugged in and Power Switch ON and IN the PRIME MODE ............................................ 18• Power cord plugged in and Power Switch ON and Gun Trigger Closed ................................................ 19• Power cord plugged in and Power Switch ON and Spray Gun Trigger Open......................................... 20Gas <strong>Texture</strong> <strong>Sprayers</strong>TexSpray 1030 FC:• Operational Overview ............................................................................................................................. 21• Pump will not prime ................................................................................................................................22• Pump will not spray................................................................................................................................. 23GM 1030 TexSpray:• Operational and troubleshooting ............................................................................................................. 24

BASIC ELECTRICAL TERMINOLOGYIn any discussion of electricity, there are three basic terms you will need to understand.CURRENTVOLTAGERESISTANCECURRENT:Current is the movement of the electrical charge.Current Flows through the wires from the power source to the load.Current is measured in AMPERES (AMPS, A or I). See Figure 1.NOTE: Meter is only clamped around one wire.ON/OFFSwitchRef 58FIGURE 1PowerPlugBlackWhiteBlackGreenRed (+)Black (–)from MotorVOLTAGE:Voltage is the force that causes current to flow in a circuit.Voltage is measured in VOLTS (V or E). See Figure 2.120 ACON/OFFSwitchRef 58Potentiometer Ref 37FIGURE 2VPowerPlugBlackBlackGreenWhiteMotorRed (+)Black (–)3

BASIC ELECTRICAL TERMINOLOGYRESISTANCE:Resistance is anything that causes an opposition to the flow of current in a circuit.Resistance is used to control the amount of voltage and/or amperage in a circuit.Resistance is measured in OHMS - Ω. See Figure 3.A common component check would be motor and clutch field windings.FIGURE 3Known Value-BlackRedYelYelKnown Value+-4

CONTINUITY TESTINGChecking “continuity” is one of the most common tests in electrical troubleshooting. Continuity is the ability of a wire or electrical component toconduct current. When you use a continuity tester, you connect a circuit (the continuity tester) that you know works, to a wire or a component thatmay or may not work. The continuity tester will tell you if the wire or component is capable of conducting current.Continuity testers are available at almost any hardware store.A volt-ohmmeter or VOM can also be used to check continuity. This meter can be purchased at most electrical or electronic supply stores.To test a component for continuity:1 Check the tester by connecting the leads.* If using a test light the light should turn on.* If using a digital volt-ohmmeter, the screen should show 00 if OL appears the meter needs to be repaired.0.000SWITCH TESTING-ROCKERCommon test procedure for a SPST Switch:5

WIRE CONTINUITY TESTINGContinuity testing will “NOT” find wire fragmentation!!Example:120 Vac input static voltage and drops to 119Vac load voltage.A good piece of wire will carry line and load voltage.Damaged / Fragmented WireDamaged / Fragmented WirePinched Wire120 Vac input static voltage and drops to 76Vac load voltage.Other causes:Poor stripping of outer insulation.Poor crimp.A defective piece of wire may carry line voltage but will “NOT” carry load voltage6

GROUND TESTINGImproper installation or alteration of grounding plug could results in risk of electric shock, fire or explosion that could cause serious injury or death.The other function of the grounding plug is to protect the control board from static build up. If the plug is missing this could cause permanent damageto the control board.Every corded electric sprayer that comes into your shop for repair should be tested as described below, to make sure that it is properly grounded.Pull the machine’s plug out of the wall outlet and connect one lead from a DC continuity test light or a VOM to the (round) ground terminal on theplug.NOTE:If the ground terminal is broken off of the plug, install a new plug.Touch the test light (or VOM) leads to several bare metal surfaces on the body of the machine. If the light (or meter) indicates continuity, the machineis properly grounded. If the light (or meter) doesn’t indicate continuity trace through the ground (green) wiring on the machine to determine wherethe break is.7

CAPACITOR TESTING:A capacitor is an electrical component that stores electricity. Capacitors are usually used to help start a motor or make a motor run more effThe following instructions can be used to test any capacitor.WARNING!A CAPACITOR CAN SHOCK YOU EVEN WHEN A MACHINE IS UNPLUGGED. NEVER TOUCH CAPACITOR TERMINALS WITHYOUR FINGERS. ALWAYS USE TOOLS WITH INSULATED HANDLES. NEVER DISCHARGE A CAPACITOR NEAR FLAMMABLELIQUIDS OR VAPORS.1 Visually inspect the capacitor for leaks, mechanically damage or loose terminals. Replace it if any of these problems exist.2 Unplug the machine and remove the capacitor(s).If capacitor(s) are attached to the control board the test can not be perormed.3 “SEE ABOVE WARNING” Using a screwdriver withinsulated handles, hold so that the blade contacts thecapacitor terminals as shown in Fig. A. This will“discharge” the capacitor.4 Put a volt-Ohm meter on the R X 100 scale.FIG. ACapacitor5 While watching the meter, connect the 2 leads to the 2 terminals on the capacitor.If the capacitor is good, the meter needle will go to the right (toward 0 resistance) (Fig. 1), then to the left (toward - maximum resistance)If the meter needle goes all the way to the right and stays there, the capacitor is defective.(Fig.2)If the meter needle stays all the way to the left (doesn't move at all when connected to the capacitor), the capacitor is defective.(Fig. 3)GOOD BAD BAD8

RECTIFIER(See Fig. 1) Now we come to the most popular application of the diode: rectifcation. Simply rectifcation is the conversion of alternatingcurrent (AC) to direct current (DC). This almost always involves the use of some device that only allows one-way flow of electrons.As we have seen, this is exactly what a diode does.RECTIFIER TESTING:The following instructions can be used to test any bridge rectifer.Use a DC continuity test light or a VOM (on the R x 100 scale) for all tests.Disconnect all wires from the rectifer.1 Connect test leads as shown in Figure A. If the meter beeps, the rectifer isdefective. If the meter does not beep, go to the next step.2 Connect test leads as shown in Figure B. If the meter does not beep, therectifer is defective. If the meter beeps, go to the next step.3 Connect test leads as shown in Figure C. If the meter beeps, the rectifer isdefective. If the meter does not beep, go to the next step.4 Connect test leads as shown in Figure D. If the meter does not beep, therectifer is defective. If the meter beeps, go to the next step.5 Connect test leads as shown in Figure E. If the meter beeps, the rectifer isdefective. If the meter does not beep, go to the next step.-FIG. 1DCACAC+ DC6 Connect test leads as shown in Figure F. If the meter does not beep, the rectifer is defective. If the meter beeps, go to the next step.7 Connect test leads as shown in Figure G. If the meter beeps, the rectifer is defective. If the meter does not beep, go to the next step.8 Connect test leads as shown in Figure H. If the meter does not beep, the rectife r is defective. If the meter beeps, the rectifer is good.OL 0.000OL 0.000FIG. A FIG. B FIG. C FIG. DOL 0.000OL 0.000FIG. E FIG. F FIG. G FIG. H9

Motor will not run.RTX 650 and TX 65See step 1.Do you haveover 100 AC volts?NORepair orreplace thepower Cord.110-120 ACVStep 1Power switch ON.Cord plugged in.Meter on AC Volts110-120 ACVStep 2Power switch ON.Cord plugged in.Meter on AC VoltsYES--See step 2. Do you haveover 100 AC volts?NOReplace thepower switch.Fuse+Fuse+YESRedBlackRedBlackSee step 3.Do you haveover 100 AC volts?NOCheck the 3ampFuse, if ok repalcefuse holder.BlackGreenRedBlackGreenRedYESWhite-Replace MotorWhitePower CordWhite-WhitePower CordMotorFuseON/OFFSwitch110-120 ACVStep 3Power switch ON.Cord plugged in.Meter on AC Volts-RedBlackFuseBlackRedGreenRedRedBlackGreenChassis GroundWhiteWhitePower CordGreenBlack+-WhiteWhitePower Cord10

Motor will not run.RTX 900, 1250 and TX 90, 125Green Wire (GND)See step 1.Do you haveover 100 AC volts?YESNORepair orreplace thepower Cord.110-120 ACV-Power CordStep 1Power switch ON.Cord plugged in.Meter on AC VoltsGreenWhiteBlackBlack+WhiteMotorSee step 2. Do you haveover 100 AC volts?NOReplace thepower switch.-SwitchGreenYESReplace MotorGreen Wire (GND)White Wire110-120 ACV-Power CordStep 2Power switch ON.Cord plugged in.Meter on AC VoltsGreen Wire (GND)GreenWhiteBlackBlack+GreenWhiteMotor-Power CordSwitchMotorBlack WireSwitch11

RotoFlex Motor or Compressor motor will not run.RTX 750 and RTX 1000See pages 00, for the steps.See step 1.Do you haveover 100 AC volts?NORepair orreplace thepower Cord.YESSee step 2. Do you haveover 100 AC volts?NORepair orreplace Whitewire or wire splice.YESSee step 3.Do you haveover 100 AC volts?YESNORepair orreplace Black wirefrom power cord topower switch.See step 4.Do you haveover 100 AC volts?NOReplace thepower switch.YESSee step 5. Do you haveover 100 AC volts?NORepair orreplace Blackwire or wire splice.12

RotoFlex Motor or Compressor motor will not run.RTX 750 and RTX 1000110-120 ACV-Step 1Cord plugged in.Wires connected.Meter on AC Volts110-120 ACV-Step 2Cord plugged in.Wires connected.Meter on AC Volts110-120 ACV-Step 3Power switch ON.Cord plugged in.Wires connectedto power switch.Meter on AC VoltsWHITEGREEN-POWERCORDWHITE-GREENPOWERCORD-POWERSWITCHSELECTORSWITCHBLUEWHITE+WHITEBLACK+POWERCORDBLACKCAPACITORBLACK+WHITEBLACKBLACKBLACKMOTORPOWERSWITCHSELECTORSWITCHBLUEBLUEGREENGROUNDGREENYELLOWWHITEGREENPOWERCORD110-120 ACV-Step 4Power switch ON.Cord plugged in.Wires connectedto power switch.Meter on AC VoltsBLACKWHITEAIR COMPRESSORBLACKBLACKPOWERSWITCHSELECTORSWITCH-110-120 ACV-Step 5Power switch ON.Cord plugged in.Black Wire unpluggedfrom Selector switch.Meter on AC VoltsPOWERSWITCH-BLACKSELECTORSWITCHBLUEBLACKWHITEBLUEBLACK+POWERCORD+WHITEBLACKPOWERCORD13

RotoFlex Motor motor will not run.RTX 750 and RTX 1000Does theAir Compressormotor run?YESSee step 1.Do you haveover 100 AC volts?YESSee step 2.Do you haveover 100 AC volts?NO See Motorswill not run.NONORepair orreplace Whitewire or wire splice.Repair orreplace Blackwire or wire splice.110-120 ACV-POWERSWITCH-BLACKStep 1Power switch ON.Cord plugged in.Wires connectedto selector switch.Selector switch ON.Meter on AC VoltsSELECTORSWITCHBLUE110-120 ACV-Step 2Power switch ON.Cord plugged in.Wires connectedto selector switch.Selector switch ON.Meter on AC VoltsYESSee Capacitortest. Does theCapacitor test ok?YESNOReplace theCapacitor.To MotorYellowWHITE+WHITEGREENPOWERCORDPOWERSWITCHBLACKSELECTORSWITCH-BLUEReplace theRotoflex Motor.BLACKCAPACITORBLACKBLACKTo MotorYellowWHITE+GREENPOWERCORDMOTORWHITEPOWERSWITCHSELECTORSWITCHBLUEGREENGROUNDYELLOWGREENBLACKBLUEGREENWHITEPOWERCORDBLACKWHITEAIR COMPRESSORBLACKBLACK14

Air Compressor Motor motor will not run.RTX 750 and RTX 1000Does theRotoflex motorrun?NO See Motorswill not run.110-120 ACVStep 1Power switch ON.Cord plugged in.Meter on AC VoltsYESSee step 1.Do you haveover 100 AC volts?YESNORepair orreplace Whitewire or wire splice.--POWERSWITCHSELECTORSWITCH110-120 ACV-Step 2Power switch ON.Cord plugged in.Meter on AC VoltsSee step 2.Do you haveover 100 AC volts?YESReplace theAir Compressor.NORepair orreplace Blackwire or wire splice.CAPACITORBLACKTo MotorYellowWHITEBLUE+WHITEBLACKGREENPOWERCORDPOWERSWITCH-BLACKTo MotorYellowWHITESELECTORSWITCHBLUE+GREENPOWERCORDBLACKBLACKWHITEMOTORBLACKPOWERSWITCHSELECTORSWITCHBLUEGREENGROUNDYELLOWGREENBLUEGREENWHITEPOWERCORDBLACKWHITEAIR COMPRESSORBLACKBLACK15

RTX 1500 <strong>Electrical</strong> and Air Ladder DiagramPower cord plugged in and Power Switch Off .N/O MainPower Switch117693Load Blk120VMMotor/AirCompressorNeutral WhtGrndOpen inPrime ModeN/C Primer Switch 119064Main Valve Coil287326N/C Air FlowSensor Switch287326Air Flow15D559ValveassemblyThe Switch will remain closeduntil air flow is present. TheGun being triggered or a AirLeak will cause the ball to lift upand open the circuit.AirCompressorAir CoolerCylinder ValveCoil 15D560Gun ValveKEY<strong>Electrical</strong> Switching CircuitAir FlowExhaustedAirCoilSensor Switch15D559Valve assembly45psiExhaustedAirCylinder Valve 15D560:WithCoil Voltage Applied. This will allow airto be exhausted and the weight of themotor to push the cylinder rod in andremove tension on the Roto Flex Hose.CoilAirRegulatorAirExhaustedAirCylinder Valve16

RTX 1500 <strong>Electrical</strong> and Air Ladder DiagramPower cord plugged in and Power Switch ONN/O MainPower Switch117693Load Blk120VMMotor/AirCompressorNeutral WhtGrndOpen inPrime ModeN/C Primer Switch 119064AirCompressorMain Valve Coil287326N/C Air FlowSensor Switch287326Cylinder ValveCoil 15D560Air FlowGun Valve15D559ValveassemblyThe Switch will remain closeduntil air flow is present. TheGun being triggered or a AirLeak will cause the ball to lift upand open the circuit.KEY<strong>Electrical</strong> Load CircuitAir FlowAir CoolerCoilExhaustedAirSensor Switch15D559Valve assembly45psiExhaustedAirCylinder Valve 15D560:With Coil Voltage Applied. This will Coilallow air to be exhausted and the weight of themotor to push the cylinder rod in and removetension on the Roto Flex Hose.AirRegulatorAirExhaustedAir17

RTX 1500 <strong>Electrical</strong> and Air Ladder DiagramPower cord plugged in and Power Switch ON and IN the PRIME MODEN/O MainPower Switch117693Load Blk120VMMotor/AirCompressorNeutral WhtGrndOpen inPrime ModeN/C Primer Switch 119064AirCompressorMain Valve Coil287326N/C Air FlowSensor Switch287326Cylinder ValveCoil 15D560Air FlowGun Valve15D559ValveassemblyThe Switch will remain closeduntil air flow is present. TheGun being triggered or a AirLeak will cause the ball to lift upand open the circuit.KEY<strong>Electrical</strong> Switching CircuitAir FlowAir CoolerCoilExhaustedAirSensor Switch15D559Valve assembly45psiExhaustedAirCylinder Valve 15D560 : With No CoilVoltage.This will allow air to enter the Coilcylinder and push the cylinder rod out and puttension on the Roto Flex Hose.AirRegulatorAirExhaustedAir18

RTX 1500 <strong>Electrical</strong> and Air Ladder DiagramPower cord plugged in and Power Switch ON and Gun Trigger ClosedN/O MainPower Switch117693Load Blk120VMMotor/AirCompressorNeutral WhtGrndOpen inPrime ModeN/C Primer Switch 119064AirCompressorMain Valve Coil287326N/C Air FlowSensor Switch287326Cylinder ValveCoil 15D560Air FlowGun Valve15D559ValveassemblyThe Switch will remain closeduntil air flow is present. TheGun being triggered or a AirLeak will cause the ball to lift upand open the circuit.KEY<strong>Electrical</strong> Switching CircuitAir FlowAir CoolerCoilExhaustedAirSensor Switch15D559Valve assembly45psiExhaustedAirCylinder Valve 15D560:With Coil Voltage Applied. This will allow Coilair to be exhausted and the weight of themotor to push the cylinder rod in and removetension on the Roto Flex Hose.AirRegulatorAirExhaustedAir19

RTX 1500 <strong>Electrical</strong> and Air Ladder DiagramPower cord plugged in and Power Switch ON and Spray Gun Trigger Open .N/O MainPower Switch117693Load Blk120VMMotor/AirCompressorNeutral WhtGrndOpen inPrime ModeN/C Primer Switch 119064AirCompressorMain Valve Coil287326N/C Air FlowSensor Switch287326Cylinder ValveCoil 15D560Air FlowGun Valve15D559ValveassemblyThe Switch will remain closeduntil air flow is present. TheGun being triggered or a AirLeak will cause the ball to lift upand open the circuit.KEY<strong>Electrical</strong> Switching CircuitAir FlowAir CoolerCoilExhaustedAirSensor Switch15D559Valve assembly45psiExhaustedAirCylinder Valve 15D560 :With No Coil Voltage.This will allow air Coilto enter the cylinder and push the cylinder rodout and put tension on the Roto Flex Hose.AirRegulatorAirExhaustedAir20

1030FC <strong>Electrical</strong> and Air Ladder DiagramRotary Switch in the Off .EnginePowerNotUsedClutch CoilThermistorWht. Com.Blk. OffBlu. Prime15B671ROTORYSWITCHRed HighYel. Med.Grn. LowEngine12-18VAC234234Control BoardPinionAssembly245399AirCompressorControl Board mustsee 30psi to operate!AirRegulator0-125psiExhaustedAirFlow Sensor Kit234232Flow SwitchGun ValveThe Flow Switch will remainopen until air flow is present.The Gun being triggered ora Air Leak will cause thepiston to move towards themagnetic reed switch andclose the circuit. Once theControl Board senses theclosed circuit it will engagethe clutch and close the dumpvalve.Mac Air Valve15B683No Coil Voltage. This will allow air to enter thetop Black air hose and force the dump valveopen and allow material to be pumped back tothe supply container.BlueBlackDump Valve287127AirTransducer:Sends a signal to the control board for materialpressure and protects the sprayer from overpressurizing. Shuts pump down at 1000psi!21

EnginePowerNotUsedClutch CoilThermistor1030FC <strong>Electrical</strong> and Air Ladder DiagramRotary Switch in the Prime Mode .When the rotary switch is in the Prime position the Control Boardwill send out 8-12VDC to the clutch and the pump will engageand prime the system. Note: The dump valve remains open.Wht. Com.Blk. OffBlu. Prime15B671ROTORYSWITCH234234Control BoardRed HighYel. Med.Grn. LowEngine12-18VACPinionAssembly245399AirCompressorControl Board mustsee 30psi to operate!AirRegulator0-125psiExhaustedAirFlow Sensor Kit234232Flow SwitchGun ValveThe Flow Switch shouldremain open and have noeffect while the rotary switchis in the prime mode. If thedump valve remains closedcheck the gun and air hose forleaks, if no leaks are found,unplug the flow switch fromthe control board. If the dumpvalve opens, replace flowsensor kit 234232. If the dumpvalve still remains closedcheck the dump valve for ablockage and the Mac AirValve for a stuck spool valve.Mac Air Valve15B683No Coil Voltage. This will allow air to enter thetop Black air hose and force the dump valveopen and allow material to be pumped back tothe supply container.BlueBlackDump Valve287127AirTransducer:Sends a signal to the control board for materialpressure and protects the sprayer from overpressurizing. Shuts pump down at 1000psi!22

Engine PowerNotUsed1030FC <strong>Electrical</strong> and Air Ladder DiagramSpraying Mode:In order to spray the control board must senses 30psi or higher and the rotary switch must be in oneof the 3 settings Low/Med./High. When the spray gun is triggered the flow switch will close,sending a signal to the control board. The control board will then send voltage out to the clutchfield to start the pump. At the same time voltage will be sent to the Mac air valve coil. The coil willclose the air valve changing the direction of the air flow to the dump valve. Air will now travelthrough the blue hose to the back of the dump valve forcing it closed .When this occurs thematerial will be forced out through the material hose.Clutch CoilThermistorWht. Com.Blk. OffBlu. Prime15B671ROTORYSWITCH234234Control BoardRed HighYel. Med.Grn. LowEngine12-18VACPinionAssembly245399AirRegulator0-125psiAirCompressorMac Air Valve15B683BlueExhaustedAirBlackControl Board mustsee 30psi to operate!Flow Sensor Kit234232AirFlow SwitchGun ValveGun AirNozzleThe Flow Switch will remainopen until air flow is present.The Gun being triggered ora Air Leak will cause thepiston to move towards themagnetic reed switch andclose the circuit. Once theControl Board senses theclosed circuit it will engagethe clutch and close the dumpvalve.When Coil Voltage is present, the coil will close theair valve changing the direction of the air flow to thedump valve. Air will now travel through the bluehose to the back of the dump valve forcing it closedDump Valve287127AirTransducer:Sends a signal to the control board for materialpressure and protects the sprayer from overpressurizing. Shuts pump down at 1000psi!23

GM 1030 Tex Sprayer1. PRESSURE SWITCH (normal open) Closes when 30 psi of pressure is maintained.2. Differential PRESURE SWITCH (normal open) Closes when 5 cfms of air flow is maintained or when a air leak is present.3. Combination gauge and SAFTEY SWITCH (normal closed)Interrupts electrical flow to the clutch stopping pumping(not engine) when pressure reaches 1000 psi. .4. BRIDGE RECIFIER converts AC voltage from the engine lighting coil to DC voltage which energizes the clutch.5. 4 WAY VALVE (active when main switch is in the spray mode and switches 1 and 2 are closed) Controls air to dumpcylinder, positioning piston so as to close off the dump outlet on the dump cylinder enabling material to be sprayed.( When power is off 4-Way valve returns to the dump position relieving pressure.Blue3RedRed1Under PressureSwitchRedBlueN.C.Com. N.O.Yellow2FlowSwitchRedRedPressureGauge with builtin Over pressureswitch.BlackBrown54 WaySoleniod ValveBlack4Rectifier+ AC-ACWhiteBlackGROUNDRed from EngineBlack to ClutchWhite to ClutchEngineRedMain Switchin OFF postionBlueSprayPrimeBlueRedBlueBlueRedNCRedRedUnderPressureSwitchComNO12FlowSwitch3ExternalPressureSwitchBrownACDC +4DC -RectifierRed(+)(-)54 WaySoleniodValveBlackACWhiteClutch CoilGROUND24