LPG Products Catalogue - Cross Technical Services

LPG Products Catalogue - Cross Technical Services

LPG Products Catalogue - Cross Technical Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

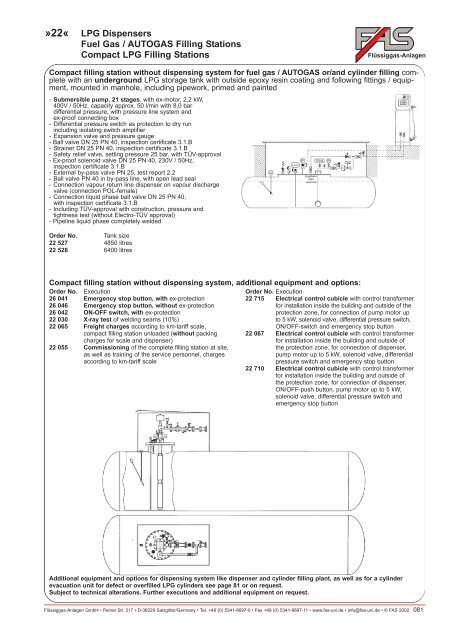

»22«<strong>LPG</strong> DispensersFuel Gas / AUTOGAS Filling StationsCompact <strong>LPG</strong> Filling StationsFlüssiggas-AnlagenCompact filling station without dispensing system for fuel gas / AUTOGAS or/and cylinder filling completewith an underground <strong>LPG</strong> storage tank with outside epoxy resin coating and following fittings / equipment,mounted in manhole, including pipework, primed and painted- Submersible pump, 21 stages, with ex-motor, 2,2 kW,400V / 50Hz, capacity approx. 50 l/min with 8,0 bardifferential pressure, with pressure line system andex-proof connecting box- Differential pressure switch as protection to dry runincluding isolating switch amplifier- Expansion valve and pressure gauge- Ball valve DN 25 PN 40, inspection certificate 3.1.B- Strainer DN 25 PN 40, inspection certificate 3.1.B- Safety relief valve, setting pressure 25 bar, with TÜV-approval- Ex-proof solenoid valve DN 25 PN 40, 230V / 50Hz,inspection certificate 3.1.B- External by-pass valve PN 25, test report 2.2- Ball valve PN 40 in by-pass line, with open lead seal- Connection vapour return line dispenser on vapour dischargevalve (connection POL-female)- Connection liquid phase ball valve DN 25 PN 40,with inspection certificate 3.1.B- Including TÜV-approval with construction, pressure andtightness test (without Electro-TÜV approval)- Pipeline liquid phase completely weldedOrder No. Tank size22 527 4850 litres22 528 6400 litres..Compact filling station without dispensing system, additional equipment and options:Order No. ExecutionOrder No. Execution26 041 Emergency stop button, with ex-protection 22 715 Electrical control cubicle with control transformer26 046 Emergency stop button, without ex-protectionfor installation inside the building and outside of the26 042 ON-OFF switch, with ex-protection protection zone, for connection of pump motor up22 030 X-ray test of welding seams (10%)to 5 kW, solenoid valve, differential pressure switch,22 065 Freight charges according to km-tariff scale,ON/OFF-switch and emergency stop buttoncompact filling station unloaded ( without packing 22 067 Electrical control cubicle with control transformercharges for scale and dispenser)for installation inside the building and outside of22 055 Commissioning of the complete filling station at site,the protection zone, for connection of dispenser,as well as training of the service personnel, chargespump motor up to 5 kW, solenoid valve, differentialaccording to km-tariff scalepressure switch and emergency stop button22 710 Electrical control cubicle with control transformerfor installation inside the building and outside ofthe protection zone, for connection of dispenser,ON/OFF-push button, pump motor up to 5 kW,solenoid valve, differential pressure switch andemergency stop buttonAdditional equipment and options for dispensing system like dispenser and cylinder filling plant, as well as for a cylinderevacuation unit for defect or overfilled <strong>LPG</strong> cylinders see page 81 or on request.Subject to technical alterations. Further executions and additional equipment on request.Flüssiggas-Anlagen GmbH • Peiner Str. 217 • D-38229 Salzgitter/Germany • Tel. +49 (0) 5341-8697-0 • Fax +49 (0) 5341-8697-11 • www.fas-uni.de • info@fas-uni.de • © FAS 2002 081