LPG Products Catalogue - Cross Technical Services

LPG Products Catalogue - Cross Technical Services

LPG Products Catalogue - Cross Technical Services

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

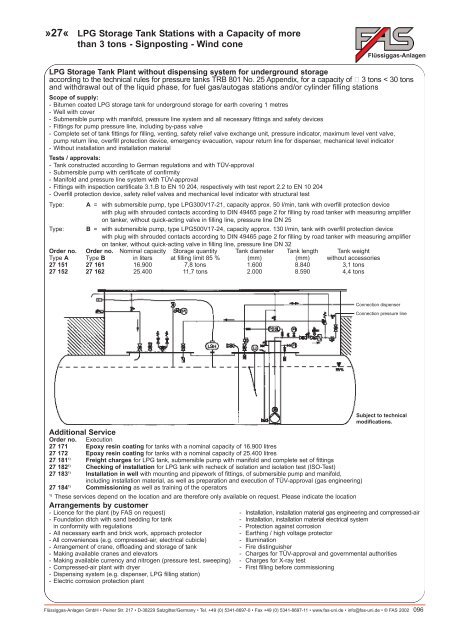

»27«<strong>LPG</strong> Storage Tank Stations with a Capacity of morethan 3 tons - Signposting - Wind coneFlüssiggas-Anlagen<strong>LPG</strong> Storage Tank Plant without dispensing system for underground storageaccording to the technical rules for pressure tanks TRB 801 No. 25 Appendix, for a capacity of 3 tons < 30 tonsand withdrawal out of the liquid phase, for fuel gas/autogas stations and/or cylinder filling stationsScope of supply:- Bitumen coated <strong>LPG</strong> storage tank for underground storage for earth covering 1 metres- Well with cover- Submersible pump with manifold, pressure line system and all necessary fittings and safety devices- Fittings for pump pressure line, including by-pass valve- Complete set of tank fittings for filling, venting, safety relief valve exchange unit, pressure indicator, maximum level vent valve,pump return line, overfill protection device, emergency evacuation, vapour return line for dispenser, mechanical level indicator- Without installation and installation materialTests / approvals:- Tank constructed according to German regulations and with TÜV-approval- Submersible pump with certificate of confirmity- Manifold and pressure line system with TÜV-approval- Fittings with inspection certificate 3.1.B to EN 10 204, respectively with test report 2.2 to EN 10 204- Overfill protection device, safety relief valves and mechanical level indicator with structural testType: A = with submersible pump, type <strong>LPG</strong>300V17-21, capacity approx. 50 l/min, tank with overfill protection devicewith plug with shrouded contacts according to DIN 49465 page 2 for filling by road tanker with measuring amplifieron tanker, without quick-acting valve in filling line, pressure line DN 25Type: B = with submersible pump, type <strong>LPG</strong>500V17-24, capacity approx. 130 l/min, tank with overfill protection devicewith plug with shrouded contacts according to DIN 49465 page 2 for filling by road tanker with measuring amplifieron tanker, without quick-acting valve in filling line, pressure line DN 32Order no. Order no. Nominal capacity Storage quantity Tank diameter Tank length Tank weightType A Type B in liters at filling limit 85 % (mm) (mm) without accessories27 151 27 161 16.900 7,8 tons 1.600 8.840 3,1 tons27 152 27 162 25.400 11,7 tons2.000 8.590 4,4 tons.Connection dispenserConnection pressure lineSubject to technicalmodifications.Additional ServiceOrder no. Execution27 171 Epoxy resin coating for tanks with a nominal capacity of 16.900 litres27 172 Epoxy resin coating for tanks with a nominal capacity of 25.400 litres27 181 1) Freight charges for <strong>LPG</strong> tank, submersible pump with manifold and complete set of fittings27 182 1)27 183 1) Checking of installation for <strong>LPG</strong> tank with recheck of isolation and isolation test (ISO-Test)Installation in well with mounting and pipework of fittings, of submersible pump and manifold,including installation material, as well as preparation and execution of TÜV-approval (gas engineering)27 184 1) Commissioning as well as training of the operators1)These services depend on the location and are therefore only available on request. Please indicate the locationArrangements by customer- Licence for the plant (by FAS on request)- Foundation ditch with sand bedding for tank--Installation, installation material gas engineering and compressed-airInstallation, installation material electrical systemin conformity with regulations- Protection against corrosion- All necessary earth and brick work, approach protector - Earthing / high voltage protector- All conveniences (e.g. compressed-air, electrical cubicle)- Arrangement of crane, offloading and storage of tank- Illumination- Fire distinguisher- Making available cranes and elevators - Charges for TÜV-approval and governmental authorities- Making available currency and nitrogen (pressure test, sweeping)- Compressed-air plant with dryer- Charges for X-ray test- First filling before commissioning- Dispensing system (e.g. dispenser, <strong>LPG</strong> filling station)- Electric corrosion protection plant.Flüssiggas-Anlagen GmbH • Peiner Str. 217 • D-38229 Salzgitter/Germany • Tel. +49 (0) 5341-8697-0 • Fax +49 (0) 5341-8697-11 • www.fas-uni.de • info@fas-uni.de • © FAS 2002 096