- Page 4 and 5: ACKNOWLEDGEMENTSThe Program Outline

- Page 6: SECTION 1OCCUPATION ANALYSIS CHARTW

- Page 13 and 14: TheoryPracticalLine DPerforms Shiel

- Page 15 and 16: Theory PracticalI-5 Describe Hoisti

- Page 17 and 18: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 19 and 20: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 21 and 22: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 23 and 24: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 25 and 26: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 27 and 28: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 29 and 30: LINE A:APPLIES OCCUPATIONAL SKILLSC

- Page 31 and 32: LINE A:APPLIES OCCUPATIONAL SKILLSC

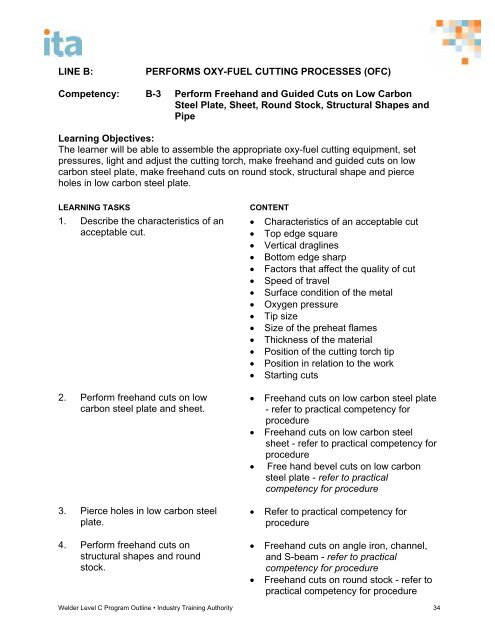

- Page 33 and 34: LINE A:Competency:APPLIES OCCUPATIO

- Page 35 and 36: NOTE: Refer To Current Welder Train

- Page 37: 5. Describe cutting torches, cuttin

- Page 41 and 42: LINE B:PERFORMS OXY-FUEL CUTTING PR

- Page 43 and 44: LINE C:PERFORMS FUSION AND BRAZE WE

- Page 45 and 46: LINE C:PERFORMS FUSION AND BRAZE WE

- Page 47 and 48: LINE C:PERFORMS FUSION AND BRAZE WE

- Page 49 and 50: LINE C:PERFORMS FUSION AND BRAZE WE

- Page 51 and 52: LINE C:PERFORMS FUSION AND BRAZE WE

- Page 53 and 54: LINE C:Competency:PERFORMS FUSION A

- Page 55 and 56: 2. Describe safety requirements,pre

- Page 57 and 58: 5. Describe and select electrodehol

- Page 59 and 60: 4. Describe correct handling andsto

- Page 61 and 62: LINE D:PERFORMS SHIELDED METAL ARC

- Page 63 and 64: LINE D:PERFORMS SHIELDED METAL ARC

- Page 65 and 66: LINE D:PERFORMS SHIELDED METAL ARC

- Page 67 and 68: 2. Demonstrate the build-up andhard

- Page 69 and 70: LINE D:Competency:PERFORMS SHIELDED

- Page 71 and 72: 3. Weld groove welds in the flat(1G

- Page 73 and 74: 6. Describe safety requirements. P

- Page 75 and 76: 4. Describe procedures for gougingc

- Page 77 and 78: 4. Describe the main factors ofPAC.

- Page 79 and 80: Welding gunToxic fumes/ventilationO

- Page 81 and 82: 4. Describe equipment for semiautom

- Page 83 and 84: LINE F:PERFORMS SEMI-AUTOMATIC WELD

- Page 85 and 86: LINE F:P)(FCAW)PERFORMS SEMI-AUTOMA

- Page 87 and 88: LINE F:P)(FCAW)PERFORMS SEMI-AUTOMA

- Page 89 and 90:

LINE F:P)(FCAW)PERFORMS SEMI-AUTOMA

- Page 91 and 92:

4. Weld fillet welds in the horizon

- Page 93 and 94:

LINE F:P)(FCAW)Competency:PERFORMS

- Page 95 and 96:

LINE F:P)(FCAW)Competency:PERFORMS

- Page 97 and 98:

LINE F:Competency:PERFORMS SEMI-AUT

- Page 99 and 100:

LINE F:P)(FCAW)Competency:PERFORMS

- Page 101 and 102:

LINE F:Competency:PERFORMS SEMI-AUT

- Page 103 and 104:

LINE F:Competency:PERFORMS SEMI-AUT

- Page 105 and 106:

LINE F:P)(FCAW)Competency:PERFORMS

- Page 107 and 108:

Achievement Criteria:The learner wi

- Page 109 and 110:

LINE F:P)(FCAW)Competency:PERFORMS

- Page 111 and 112:

LINE G:DESCRIBE BASIC METALLURGY RE

- Page 113 and 114:

LINE G:DESCRIBE BASIC METALLURGY RE

- Page 115 and 116:

LINE G:DESCRIBE BASIC METALLURGY RE

- Page 117 and 118:

LINE G:DESCRIBE BASIC METALLURGY RE

- Page 119 and 120:

LINE I:DESCRIBES AND PERFORMS MATEI

- Page 121 and 122:

4. Recognize and name commonknots,

- Page 123 and 124:

4. Identify common rigginghardware.

- Page 125 and 126:

LINE I:DESCRIBES AND PERFORMS MATER

- Page 127 and 128:

LINE J:READS WELDING DRAWINGSCompet

- Page 129 and 130:

LINE J:READS WELDING DRAWINGSCompet

- Page 131 and 132:

4. Identify the dimensioning ofbolt

- Page 133 and 134:

3. Identify bills of material and o

- Page 135 and 136:

LINE K:LAYOUT AND FABRICATE COMPONE

- Page 137 and 138:

LINE K:LAYOUT AND FABRICATE COMPONE

- Page 139 and 140:

LINE N:PERFORMS SUBMERGED ARC WELDI

- Page 141 and 142:

LINE N:PERFORMS SUBMERGED ARC WELDI

- Page 143 and 144:

LINE N:PERFORMS SUBMERGED ARC WELDI

- Page 145 and 146:

INSTRUCTORSWELDER C TRAINING PROVID

- Page 147 and 148:

STUDENT FACILITIES‣ Adequate lunc

- Page 149 and 150:

Testing EquipmentAdapter fittingsAm

- Page 151 and 152:

RECOMMENDED REFERENCETEXTBOOKSWELDE

- Page 153 and 154:

APPENDIX ONEWELDER LEVEL CFINAL WEL

- Page 155 and 156:

Welder Level C Apprenticeship Progr

- Page 159 and 160:

APPENDIX TWOWELDER LEVEL CPROGRAMFI

- Page 161 and 162:

Welder Level C Program Outline •

- Page 165 and 166:

Welder Level C Program Outline •

- Page 167 and 168:

Welder Level C Program Outline •

- Page 169:

FINAL PRACTICAL EXAMINATION #3MATER

- Page 173 and 174:

Level "C" Weld Test #1 Performance

- Page 175 and 176:

Level "C" Weld Test #2 Performance

- Page 177 and 178:

Level "C" Weld Test #3 Performance

- Page 179 and 180:

Level C Final Weld TestsPRS-CWelder

- Page 181 and 182:

In addition to the above requiremen