How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

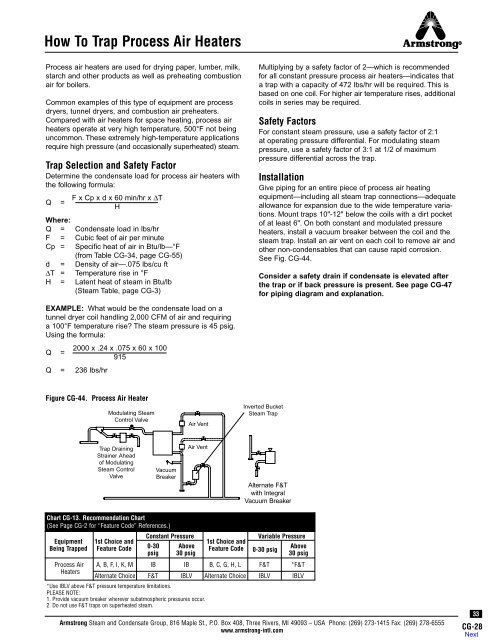

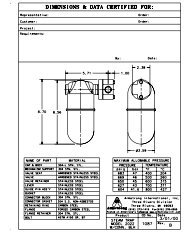

<strong>How</strong> To <strong>Trap</strong> Process Air HeatersProcess air heaters are used for drying paper, lumber, milk,starch and other products as well as preheating combustionair for boilers.Common examples of this type of equipment are processdryers, tunnel dryers, and combustion air preheaters.Compared with air heaters for space heating, process airheaters operate at very high temperature, 500°F not beinguncommon. These extremely high-temperature applicationsrequire high pressure (and occasionally superheated) steam.<strong>Trap</strong> Selection and Safety Fac<strong>to</strong>rDetermine the condensate load for process air heaters withthe following formula:Q =Where:Q = Condensate load in lbs/hrF = Cubic feet of air per minuteCp =F x Cp x d x 60 min/hr x ∆THSpecific heat of air in Btu/lb—°F(from Table CG-34, page CG-55)d = Density of air—.075 lbs/cu ft∆T = Temperature rise in °FH = Latent heat of steam in Btu/lb(<strong>Steam</strong> Table, page CG-3)Multiplying by a safety fac<strong>to</strong>r of 2—which is recommendedfor all constant pressure process air heaters—indicates thata trap with a capacity of 472 lbs/hr will be required. This isbased on one coil. For higher air temperature rises, additionalcoils in series may be required.Safety Fac<strong>to</strong>rsFor constant steam pressure, use a safety fac<strong>to</strong>r of 2:1at operating pressure differential. For modulating steampressure, use a safety fac<strong>to</strong>r of 3:1 at 1/2 of maximumpressure differential across the trap.InstallationGive piping for an entire piece of process air heatingequipment—including all steam trap connections—adequateallowance for expansion due <strong>to</strong> the wide temperature variations.Mount traps 10"-12" below the coils with a dirt pocke<strong>to</strong>f at least 6". On both constant and modulated pressureheaters, install a vacuum breaker between the coil and thesteam trap. Install an air vent on each coil <strong>to</strong> remove air andother non-condensables that can cause rapid corrosion.See Fig. CG-44.Consider a safety drain if condensate is elevated afterthe trap or if back pressure is present. See page CG-47for piping diagram and explanation.EXAMPLE: What would be the condensate load on atunnel dryer coil handling 2,000 CFM of air and requiringa 100°F temperature rise? The steam pressure is 45 psig.Using the formula:Q =2000 x .24 x .075 x 60 x 100915Q = 236 lbs/hrFigure CG-44. Process Air HeaterModulating <strong>Steam</strong>Control ValveAir VentInverted Bucket<strong>Steam</strong> <strong>Trap</strong><strong>Trap</strong> DrainingStrainer Aheadof Modulating<strong>Steam</strong> ControlValveVacuumBreakerAir VentAlternate F&Twith IntegralVacuum BreakerChart CG-13. Recommendation Chart(See Page CG-2 for “Feature Code” References.)EquipmentBeing <strong>Trap</strong>ped1st Choice andFeature CodeConstant Pressure0-30psigAbove30 psig1st Choice andFeature CodeVariable Pressure0-30 psigAbove30 psigProcess AirHeatersAlternate Choice F&T IBLV Alternate Choice IBLV IBLV*Use IBLV above F&T pressure temperature limitations.PLEASE NOTE:1. Provide vacuum breaker wherever subatmospheric pressures occur.2. Do not use F&T traps on superheated steam.A, B, F, I, K, M IB IB B, C, G, H, L F&T *F&T<strong>Armstrong</strong> <strong>Steam</strong> and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555www.armstrong-intl.com33CG-28