How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

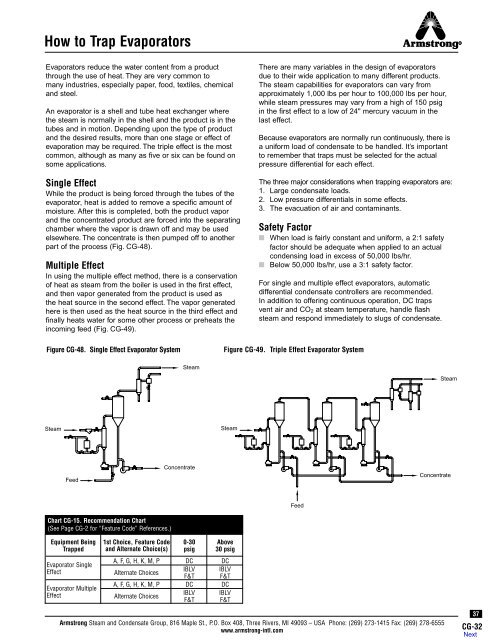

<strong>How</strong> <strong>to</strong> <strong>Trap</strong> Evapora<strong>to</strong>rsEvapora<strong>to</strong>rs reduce the water content from a productthrough the use of heat. They are very common <strong>to</strong>many industries, especially paper, food, textiles, chemicaland steel.An evapora<strong>to</strong>r is a shell and tube heat exchanger wherethe steam is normally in the shell and the product is in thetubes and in motion. Depending upon the type of productand the desired results, more than one stage or effect ofevaporation may be required. The triple effect is the mostcommon, although as many as five or six can be found onsome applications.Single EffectWhile the product is being forced through the tubes of theevapora<strong>to</strong>r, heat is added <strong>to</strong> remove a specific amount ofmoisture. After this is completed, both the product vaporand the concentrated product are forced in<strong>to</strong> the separatingchamber where the vapor is drawn off and may be usedelsewhere. The concentrate is then pumped off <strong>to</strong> anotherpart of the process (Fig. CG-48).Multiple EffectIn using the multiple effect method, there is a conservationof heat as steam from the boiler is used in the first effect,and then vapor generated from the product is used asthe heat source in the second effect. The vapor generatedhere is then used as the heat source in the third effect andfinally heats water for some other process or preheats theincoming feed (Fig. CG-49).There are many variables in the design of evapora<strong>to</strong>rsdue <strong>to</strong> their wide application <strong>to</strong> many different products.The steam capabilities for evapora<strong>to</strong>rs can vary fromapproximately 1,000 lbs per hour <strong>to</strong> 100,000 lbs per hour,while steam pressures may vary from a high of 150 psigin the first effect <strong>to</strong> a low of 24'' mercury vacuum in thelast effect.Because evapora<strong>to</strong>rs are normally run continuously, there isa uniform load of condensate <strong>to</strong> be handled. It’s important<strong>to</strong> remember that traps must be selected for the actualpressure differential for each effect.The three major considerations when trapping evapora<strong>to</strong>rs are:1. Large condensate loads.2. Low pressure differentials in some effects.3. The evacuation of air and contaminants.Safety Fac<strong>to</strong>r■ When load is fairly constant and uniform, a 2:1 safetyfac<strong>to</strong>r should be adequate when applied <strong>to</strong> an actualcondensing load in excess of 50,000 lbs/hr.■ Below 50,000 lbs/hr, use a 3:1 safety fac<strong>to</strong>r.For single and multiple effect evapora<strong>to</strong>rs, au<strong>to</strong>maticdifferential condensate controllers are recommended.In addition <strong>to</strong> offering continuous operation, DC trapsvent air and CO 2 at steam temperature, handle flashsteam and respond immediately <strong>to</strong> slugs of condensate.Figure CG-48. Single Effect Evapora<strong>to</strong>r SystemFigure CG-49. Triple Effect Evapora<strong>to</strong>r System<strong>Steam</strong><strong>Steam</strong><strong>Steam</strong><strong>Steam</strong>FeedConcentrateConcentrateFeedChart CG-15. Recommendation Chart(See Page CG-2 for “Feature Code” References.)Equipment Being<strong>Trap</strong>pedEvapora<strong>to</strong>r SingleEffectEvapora<strong>to</strong>r MultipleEffect1st Choice, Feature Codeand Alternate Choice(s)0-30psigAbove30 psigA, F, G, H, K, M, P DC DCIBLV IBLVAlternate ChoicesF&T F&TA, F, G, H, K, M, P DC DCIBLV IBLVAlternate ChoicesF&T F&T<strong>Armstrong</strong> <strong>Steam</strong> and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555www.armstrong-intl.com37CG-32