How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

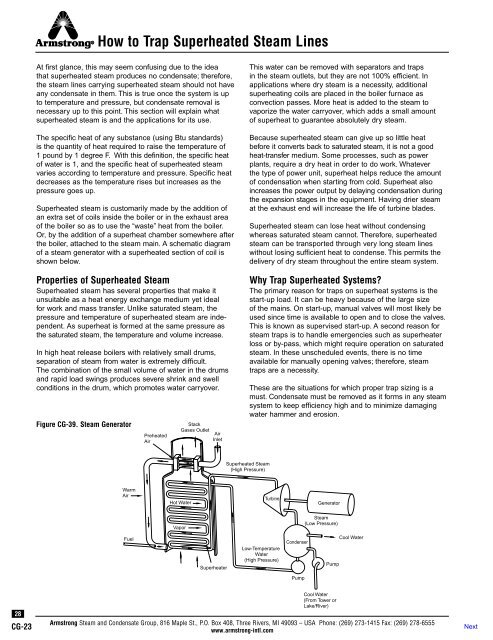

<strong>How</strong> <strong>to</strong> <strong>Trap</strong> Superheated <strong>Steam</strong> LinesAt first glance, this may seem confusing due <strong>to</strong> the ideathat superheated steam produces no condensate; therefore,the steam lines carrying superheated steam should not haveany condensate in them. This is true once the system is up<strong>to</strong> temperature and pressure, but condensate removal isnecessary up <strong>to</strong> this point. This section will explain whatsuperheated steam is and the applications for its use.The specific heat of any substance (using Btu standards)is the quantity of heat required <strong>to</strong> raise the temperature of1 pound by 1 degree F. With this definition, the specific hea<strong>to</strong>f water is 1, and the specific heat of superheated steamvaries according <strong>to</strong> temperature and pressure. Specific heatdecreases as the temperature rises but increases as thepressure goes up.Superheated steam is cus<strong>to</strong>marily made by the addition ofan extra set of coils inside the boiler or in the exhaust areaof the boiler so as <strong>to</strong> use the “waste” heat from the boiler.Or, by the addition of a superheat chamber somewhere afterthe boiler, attached <strong>to</strong> the steam main. A schematic diagramof a steam genera<strong>to</strong>r with a superheated section of coil isshown below.Properties of Superheated <strong>Steam</strong>Superheated steam has several properties that make itunsuitable as a heat energy exchange medium yet idealfor work and mass transfer. Unlike saturated steam, thepressure and temperature of superheated steam are independent.As superheat is formed at the same pressure asthe saturated steam, the temperature and volume increase.In high heat release boilers with relatively small drums,separation of steam from water is extremely difficult.The combination of the small volume of water in the drumsand rapid load swings produces severe shrink and swellconditions in the drum, which promotes water carryover.Figure CG-39. <strong>Steam</strong> Genera<strong>to</strong>rPreheatedAirStackGases OutletAirInletThis water can be removed with separa<strong>to</strong>rs and trapsin the steam outlets, but they are not 100% efficient. Inapplications where dry steam is a necessity, additionalsuperheating coils are placed in the boiler furnace asconvection passes. More heat is added <strong>to</strong> the steam <strong>to</strong>vaporize the water carryover, which adds a small amoun<strong>to</strong>f superheat <strong>to</strong> guarantee absolutely dry steam.Because superheated steam can give up so little heatbefore it converts back <strong>to</strong> saturated steam, it is not a goodheat-transfer medium. Some processes, such as powerplants, require a dry heat in order <strong>to</strong> do work. Whateverthe type of power unit, superheat helps reduce the amoun<strong>to</strong>f condensation when starting from cold. Superheat alsoincreases the power output by delaying condensation duringthe expansion stages in the equipment. Having drier steamat the exhaust end will increase the life of turbine blades.Superheated steam can lose heat without condensingwhereas saturated steam cannot. Therefore, superheatedsteam can be transported through very long steam lineswithout losing sufficient heat <strong>to</strong> condense. This permits thedelivery of dry steam throughout the entire steam system.Why <strong>Trap</strong> Superheated <strong>Systems</strong>?The primary reason for traps on superheat systems is thestart-up load. It can be heavy because of the large sizeof the mains. On start-up, manual valves will most likely beused since time is available <strong>to</strong> open and <strong>to</strong> close the valves.This is known as supervised start-up. A second reason forsteam traps is <strong>to</strong> handle emergencies such as superheaterloss or by-pass, which might require operation on saturatedsteam. In these unscheduled events, there is no timeavailable for manually opening valves; therefore, steamtraps are a necessity.These are the situations for which proper trap sizing is amust. Condensate must be removed as it forms in any steamsystem <strong>to</strong> keep efficiency high and <strong>to</strong> minimize damagingwater hammer and erosion.Superheated <strong>Steam</strong>(High Pressure)WarmAirHot WaterTurbineGenera<strong>to</strong>rVapor<strong>Steam</strong>(Low Pressure)FuelSuperheaterLow-TemperatureWater(High Pressure)CondenserPumpCool WaterPump28CG-23Cool Water(From Tower orLake/River)<strong>Armstrong</strong> <strong>Steam</strong> and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555www.armstrong-intl.com