How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

How to Trap Steam Distribution Systems - Armstrong International, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

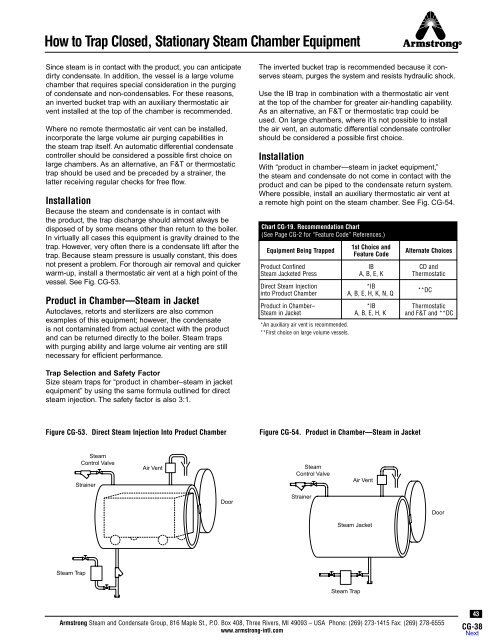

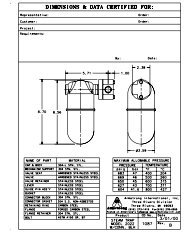

<strong>How</strong> <strong>to</strong> <strong>Trap</strong> Closed, Stationary <strong>Steam</strong> Chamber EquipmentSince steam is in contact with the product, you can anticipatedirty condensate. In addition, the vessel is a large volumechamber that requires special consideration in the purgingof condensate and non-condensables. For these reasons,an inverted bucket trap with an auxiliary thermostatic airvent installed at the <strong>to</strong>p of the chamber is recommended.Where no remote thermostatic air vent can be installed,incorporate the large volume air purging capabilities inthe steam trap itself. An au<strong>to</strong>matic differential condensatecontroller should be considered a possible first choice onlarge chambers. As an alternative, an F&T or thermostatictrap should be used and be preceded by a strainer, thelatter receiving regular checks for free flow.InstallationBecause the steam and condensate is in contact withthe product, the trap discharge should almost always bedisposed of by some means other than return <strong>to</strong> the boiler.In virtually all cases this equipment is gravity drained <strong>to</strong> thetrap. <strong>How</strong>ever, very often there is a condensate lift after thetrap. Because steam pressure is usually constant, this doesnot present a problem. For thorough air removal and quickerwarm-up, install a thermostatic air vent at a high point of thevessel. See Fig. CG-53.Product in Chamber—<strong>Steam</strong> in JacketAu<strong>to</strong>claves, re<strong>to</strong>rts and sterilizers are also commonexamples of this equipment; however, the condensateis not contaminated from actual contact with the productand can be returned directly <strong>to</strong> the boiler. <strong>Steam</strong> trapswith purging ability and large volume air venting are stillnecessary for efficient performance.The inverted bucket trap is recommended because it conservessteam, purges the system and resists hydraulic shock.Use the IB trap in combination with a thermostatic air ventat the <strong>to</strong>p of the chamber for greater air-handling capability.As an alternative, an F&T or thermostatic trap could beused. On large chambers, where it’s not possible <strong>to</strong> installthe air vent, an au<strong>to</strong>matic differential condensate controllershould be considered a possible first choice.InstallationWith “product in chamber—steam in jacket equipment,”the steam and condensate do not come in contact with theproduct and can be piped <strong>to</strong> the condensate return system.Where possible, install an auxiliary thermostatic air vent ata remote high point on the steam chamber. See Fig. CG-54.Chart CG-19. Recommendation Chart(See Page CG-2 for “Feature Code” References.)Equipment Being <strong>Trap</strong>pedProduct Confined<strong>Steam</strong> Jacketed PressDirect <strong>Steam</strong> Injectionin<strong>to</strong> Product ChamberProduct in Chamber–<strong>Steam</strong> in Jacket*An auxiliary air vent is recommended.**First choice on large volume vessels.1st Choice andFeature CodeIBA, B, E, K*IBA, B, E, H, K, N, Q*IBA, B, E, H, KAlternate ChoicesCD andThermostatic**DCThermostaticand F&T and **DC<strong>Trap</strong> Selection and Safety Fac<strong>to</strong>rSize steam traps for “product in chamber–steam in jacketequipment” by using the same formula outlined for directsteam injection. The safety fac<strong>to</strong>r is also 3:1.Figure CG-53. Direct <strong>Steam</strong> Injection In<strong>to</strong> Product ChamberFigure CG-54. Product in Chamber—<strong>Steam</strong> in Jacket<strong>Steam</strong>Control ValveStrainerAir Vent<strong>Steam</strong>Control ValveAir VentDoorStrainerDoor<strong>Steam</strong> Jacket<strong>Steam</strong> <strong>Trap</strong><strong>Steam</strong> <strong>Trap</strong><strong>Armstrong</strong> <strong>Steam</strong> and Condensate Group, 816 Maple St., P.O. Box 408, Three Rivers, MI 49093 – USA Phone: (269) 273-1415 Fax: (269) 278-6555www.armstrong-intl.com43CG-38