You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

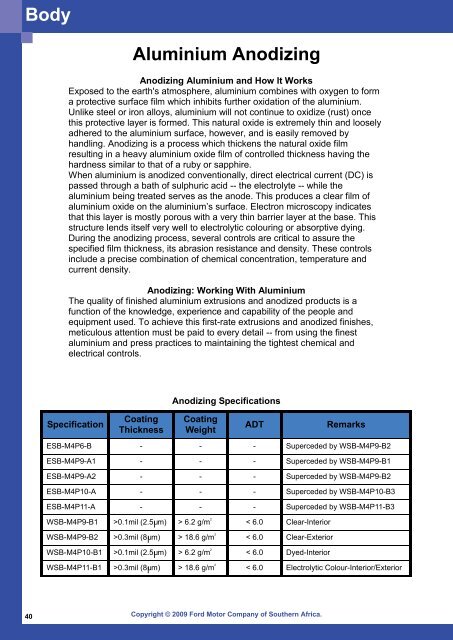

BodyAluminium AnodizingAnodizing Aluminium and How It WorksExposed to the earth's atmosphere, aluminium combines with oxygen to forma protective surface film which inhibits further oxidation of the aluminium.Unlike steel or iron alloys, aluminium will not continue to oxidize (rust) oncethis protective layer is formed. This natural oxide is extremely thin and looselyadhered to the aluminium surface, however, and is easily removed byhandling. Anodizing is a process which thickens the natural oxide filmresulting in a heavy aluminium oxide film of controlled thickness having thehardness similar to that of a ruby or sapphire.When aluminium is anodized conventionally, direct electrical current (DC) ispassed through a bath of sulphuric acid -- the electrolyte -- while thealuminium being treated serves as the anode. This produces a clear film ofaluminium oxide on the aluminium’s surface. Electron microscopy indicatesthat this layer is mostly porous with a very thin barrier layer at the base. Thisstructure lends itself very well to electrolytic colouring or absorptive dying.During the anodizing process, several controls are critical to assure thespecified film thickness, its abrasion resistance and density. These controlsinclude a precise combination of chemical concentration, temperature andcurrent density.Anodizing: Working With AluminiumThe quality of finished aluminium extrusions and anodized products is afunction of the knowledge, experience and capability of the people andequipment used. To achieve this first-rate extrusions and anodized finishes,meticulous attention must be paid to every detail -- from using the finestaluminium and press practices to maintaining the tightest chemical andelectrical controls.Anodizing SpecificationsSpecificationCoatingThicknessCoatingWeightADTRemarksESB-M4P6-B - - - Superceded by WSB-M4P9-B2ESB-M4P9-A1 - - - Superceded by WSB-M4P9-B1ESB-M4P9-A2 - - - Superceded by WSB-M4P9-B2ESB-M4P10-A - - - Superceded by WSB-M4P10-B3ESB-M4P11-A - - - Superceded by WSB-M4P11-B3WSB-M4P9-B12>0.1mil (2.5 um) > 6.2 g/m < 6.0 Clear-InteriorWSB-M4P9-B22>0.3mil (8 um) > 18.6 g/m < 6.0 Clear-ExteriorWSB-M4P10-B12>0.1mil (2.5 um) > 6.2 g/m < 6.0 Dyed-InteriorWSB-M4P11-B12>0.3mil (8 um) > 18.6 g/m < 6.0 Electrolytic Colour-Interior/Exterior40Copyright © 2009 <strong>Ford</strong> Motor Company of Southern Africa.