You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

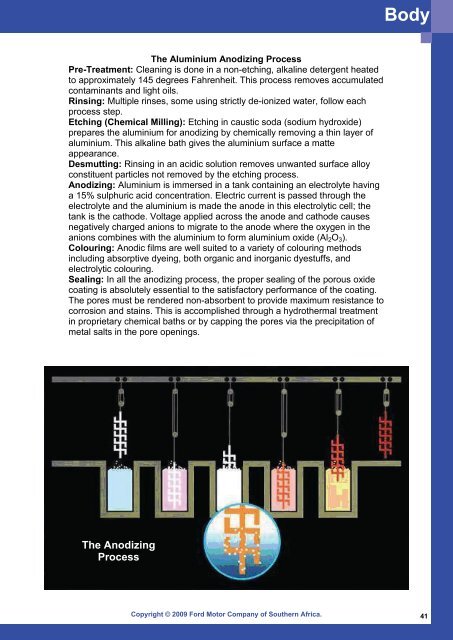

BodyThe Aluminium Anodizing ProcessPre-Treatment: Cleaning is done in a non-etching, alkaline detergent heatedto approximately 145 degrees Fahrenheit. This process removes accumulatedcontaminants and light oils.Rinsing: Multiple rinses, some using strictly de-ionized water, follow eachprocess step.Etching (Chemical Milling): Etching in caustic soda (sodium hydroxide)prepares the aluminium for anodizing by chemically removing a thin layer ofaluminium. This alkaline bath gives the aluminium surface a matteappearance.Desmutting: Rinsing in an acidic solution removes unwanted surface alloyconstituent particles not removed by the etching process.Anodizing: Aluminium is immersed in a tank containing an electrolyte havinga 15% sulphuric acid concentration. Electric current is passed through theelectrolyte and the aluminium is made the anode in this electrolytic cell; thetank is the cathode. Voltage applied across the anode and cathode causesnegatively charged anions to migrate to the anode where the oxygen in theanions combines with the aluminium to form aluminium oxide (Al 2 O 3 ).Colouring: Anodic films are well suited to a variety of colouring methodsincluding absorptive dyeing, both organic and inorganic dyestuffs, andelectrolytic colouring.Sealing: In all the anodizing process, the proper sealing of the porous oxidecoating is absolutely essential to the satisfactory performance of the coating.The pores must be rendered non-absorbent to provide maximum resistance tocorrosion and stains. This is accomplished through a hydrothermal treatmentin proprietary chemical baths or by capping the pores via the precipitation ofmetal salts in the pore openings.The AnodizingProcessCopyright © 2009 <strong>Ford</strong> Motor Company of Southern Africa. 41