INFOBALE - Hjallerup Maskinforretning A/S

INFOBALE - Hjallerup Maskinforretning A/S

INFOBALE - Hjallerup Maskinforretning A/S

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

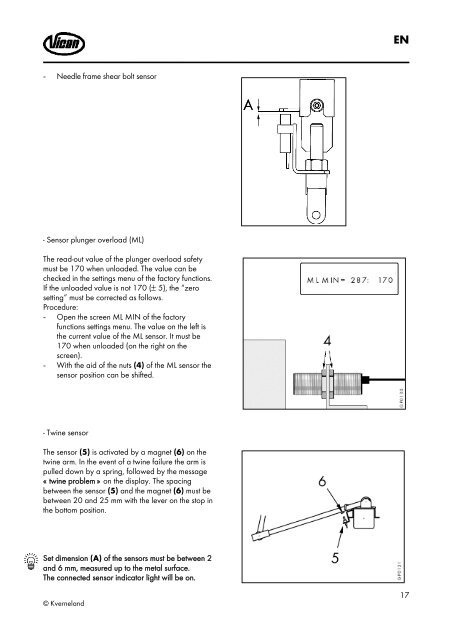

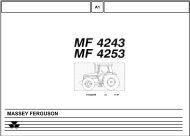

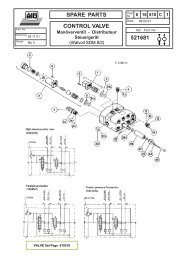

EN- Needle frame shear bolt sensor- Sensor plunger overload (ML)The read-out value of the plunger overload safetymust be 170 when unloaded. The value can bechecked in the settings menu of the factory functions.If the unloaded value is not 170 (± 5), the “zerosetting” must be corrected as follows.Procedure:- Open the screen ML MIN of the factoryfunctions settings menu. The value on the left isthe current value of the ML sensor. It must be170 when unloaded (on the right on thescreen).- With the aid of the nuts (4) of the ML sensor thesensor position can be shifted.- Twine sensorThe sensor (5) is activated by a magnet (6) on thetwine arm. In the event of a twine failure the arm ispulled down by a spring, followed by the message« twine problem » on the display. The spacingbetween the sensor (5) and the magnet (6) must bebetween 20 and 25 mm with the lever on the stop inthe bottom position.Set dimension (A) of the sensors must be between 2and 6 mm, measured up to the metal surface.The connected sensor indicator light will be on.© Kverneland17