Principles and Practical Aspects of Preparative Liquid Chromatography

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3.2.2 Fixed-loop design<br />

<strong>of</strong> autosampler<br />

When working with a system where – in alternating mode –<br />

analytical‐scale <strong>and</strong> preparative scale injection volumes are required, the<br />

size <strong>of</strong> the sample loop <strong>of</strong> a flow-through-needle design <strong>of</strong> autosampler<br />

will contribute significantly to the dwell volume. Systems with large dwell<br />

volumes will not perform well when using analytical flow rates. For these<br />

applications the fixed-loop design <strong>of</strong> autosampler with two sample loops<br />

<strong>of</strong> different sizes can eliminate this dilemma. A switching valve is used<br />

to create completely separate analytical <strong>and</strong> preparative flow paths.<br />

Nevertheless, there are several aspects we need to consider to be able<br />

to work successfully with this fixed-loop design <strong>of</strong> autosampler with<br />

dual loops.<br />

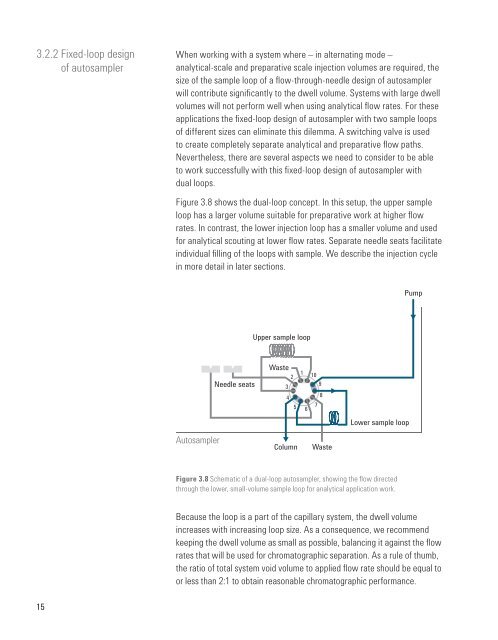

Figure 3.8 shows the dual-loop concept. In this setup, the upper sample<br />

loop has a larger volume suitable for preparative work at higher flow<br />

rates. In contrast, the lower injection loop has a smaller volume <strong>and</strong> used<br />

for analytical scouting at lower flow rates. Separate needle seats facilitate<br />

individual filling <strong>of</strong> the loops with sample. We describe the injection cycle<br />

in more detail in later sections.<br />

Pump<br />

Upper sample loop<br />

Autosampler<br />

Needle seats<br />

Waste<br />

2<br />

3<br />

4<br />

5<br />

Column<br />

1 10<br />

9<br />

6<br />

7<br />

8<br />

Waste<br />

Lower sample loop<br />

Figure 3.8 Schematic <strong>of</strong> a dual-loop autosampler, showing the flow directed<br />

through the lower, small-volume sample loop for analytical application work.<br />

Because the loop is a part <strong>of</strong> the capillary system, the dwell volume<br />

increases with increasing loop size. As a consequence, we recommend<br />

keeping the dwell volume as small as possible, balancing it against the flow<br />

rates that will be used for chromatographic separation. As a rule <strong>of</strong> thumb,<br />

the ratio <strong>of</strong> total system void volume to applied flow rate should be equal to<br />

or less than 2:1 to obtain reasonable chromatographic performance.<br />

15