Compiled Embroidery Skill Articles

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

10/28/2016 Getting Started Part 2 Troubleshooting Bad <strong>Embroidery</strong> <strong>Embroidery</strong> Article<br />

4 Reviews<br />

Getting Started Part 2 <br />

Troubleshooting Bad <strong>Embroidery</strong><br />

By Bonnie Landsberger on February 22, 2015<br />

Share Your Project<br />

(Click Image to Enlarge)<br />

0 0 0<br />

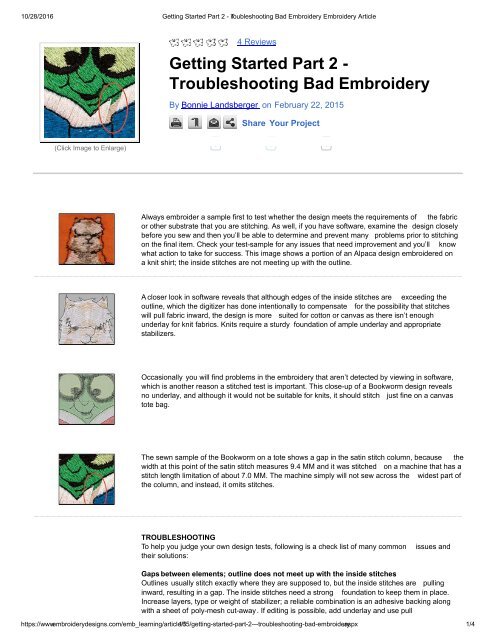

Always embroider a sample first to test whether the design meets the requirements of the fabric<br />

or other substrate that you are stitching. As well, if you have software, examine the design closely<br />

before you sew and then you’ll be able to determine and prevent many problems prior to stitching<br />

on the final item. Check your testsample for any issues that need improvement and you’ll know<br />

what action to take for success. This image shows a portion of an Alpaca design embroidered on<br />

a knit shirt; the inside stitches are not meeting up with the outline.<br />

A closer look in software reveals that although edges of the inside stitches are exceeding the<br />

outline, which the digitizer has done intentionally to compensate for the possibility that stitches<br />

will pull fabric inward, the design is more suited for cotton or canvas as there isn’t enough<br />

underlay for knit fabrics. Knits require a sturdy foundation of ample underlay and appropriate<br />

stabilizers.<br />

Occasionally you will find problems in the embroidery that aren’t detected by viewing in software,<br />

which is another reason a stitched test is important. This closeup of a Bookworm design reveals<br />

no underlay, and although it would not be suitable for knits, it should stitch just fine on a canvas<br />

tote bag.<br />

The sewn sample of the Bookworm on a tote shows a gap in the satin stitch column, because the<br />

width at this point of the satin stitch measures 9.4 MM and it was stitched on a machine that has a<br />

stitch length limitation of about 7.0 MM. The machine simply will not sew across the widest part of<br />

the column, and instead, it omits stitches.<br />

TROUBLESHOOTING<br />

To help you judge your own design tests, following is a check list of many common<br />

their solutions:<br />

issues and<br />

Gaps between elements; outline does not meet up with the inside stitches:<br />

Outlines usually stitch exactly where they are supposed to, but the inside stitches are pulling<br />

inward, resulting in a gap. The inside stitches need a strong foundation to keep them in place.<br />

Increase layers, type or weight of stabilizer; a reliable combination is an adhesive backing along<br />

with a sheet of polymesh cutaway. If editing is possible, add underlay and use pull<br />

https://www.embroiderydesigns.com/emb_learning/article/1<br />

compensation<br />

165/gettingstartedpart2troubleshootingbadembroidery<br />

to extend sides where stitches pull inward.<br />

.aspx 1/4