Compiled Embroidery Skill Articles

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

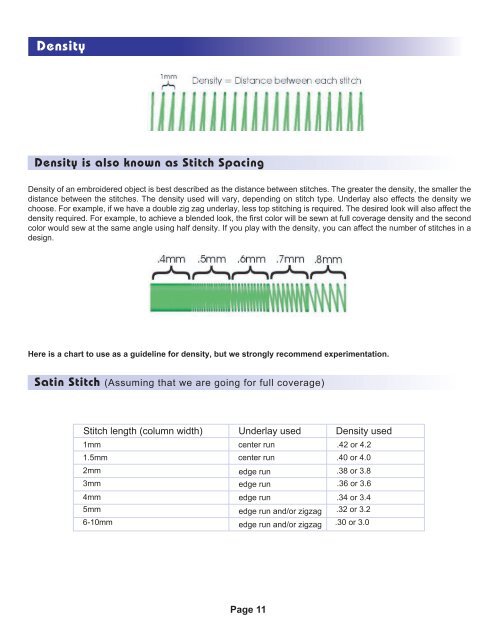

Density<br />

Density is also known as Stitch Spacing<br />

Density of an embroidered object is best described as the distance between stitches. The greater the density, the smaller the<br />

distance between the stitches. The density used will vary, depending on stitch type. Underlay also effects the density we<br />

choose. For example, if we have a double zig zag underlay, less top stitching is required. The desired look will also affect the<br />

density required. For example, to achieve a blended look, the first color will be sewn at full coverage density and the second<br />

color would sew at the same angle using half density. If you play with the density, you can affect the number of stitches in a<br />

design.<br />

Here is a chart to use as a guideline for density, but we strongly recommend experimentation.<br />

Satin Stitch (Assuming that we are going for full coverage)<br />

Stitch length (column width) Underlay used Density used<br />

1mm center run .42 or 4.2<br />

1.5mm<br />

center run .40 or 4.0<br />

2mm<br />

3mm<br />

edge run<br />

edge run<br />

.38 or 3.8<br />

.36 or 3.6<br />

4mm<br />

edge run<br />

.34 or 3.4<br />

5mm edge run and/or zigzag .32 or 3.2<br />

6-10mm edge run and/or zigzag .30 or 3.0<br />

Page 11