CPT International 01/2015

The leading technical journal for the global foundry industry – Das führende Fachmagazin für die weltweite Gießerei-Industrie

The leading technical journal for the

global foundry industry – Das führende Fachmagazin für die

weltweite Gießerei-Industrie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

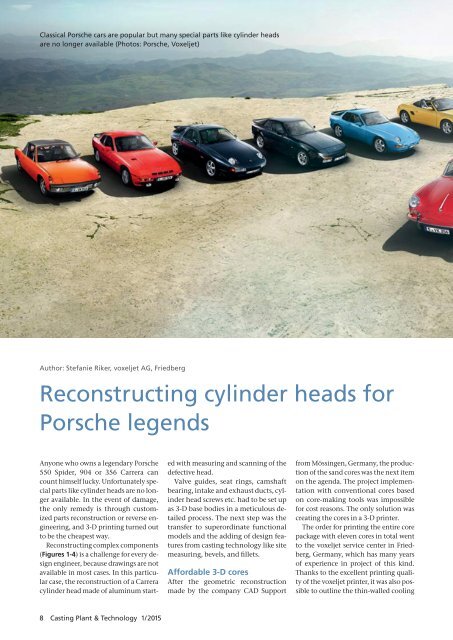

Classical Porsche cars are popular but many special parts like cylinder heads<br />

are no longer available (Photos: Por sche, Voxeljet)<br />

Author: Stefanie Riker, voxeljet AG, Friedberg<br />

Reconstructing cylinder heads for<br />

Porsche legends<br />

Anyone who owns a legendary Porsche<br />

550 Spider, 904 or 356 Carrera can<br />

count himself lucky. Unfortunately special<br />

parts like cylinder heads are no longer<br />

available. In the event of damage,<br />

the only remedy is through customized<br />

parts reconstruction or reverse engineering,<br />

and 3-D printing turned out<br />

to be the cheapest way.<br />

Reconstructing complex components<br />

(Figures 1-4) is a challenge for every design<br />

engineer, because drawings are not<br />

available in most cases. In this particular<br />

case, the reconstruction of a Carrera<br />

cylinder head made of aluminum started<br />

with measuring and scanning of the<br />

defective head.<br />

Valve guides, seat rings, camshaft<br />

bearing, intake and exhaust ducts, cylinder<br />

head screws etc. had to be set up<br />

as 3-D base bodies in a meticulous detailed<br />

process. The next step was the<br />

transfer to superordinate functional<br />

models and the adding of design features<br />

from casting technology like site<br />

measuring, bevels, and fillets.<br />

Affordable 3-D cores<br />

After the geometric reconstruction<br />

made by the company CAD Support<br />

from Mössingen, Germany, the production<br />

of the sand cores was the next item<br />

on the agenda. The project implementation<br />

with conventional cores based<br />

on core-making tools was impossible<br />

for cost reasons. The only solution was<br />

creating the cores in a 3-D printer.<br />

The order for printing the entire core<br />

package with eleven cores in total went<br />

to the voxeljet service center in Friedberg,<br />

Germany, which has many years<br />

of experience in project of this kind.<br />

Thanks to the excellent printing quality<br />

of the voxeljet printer, it was also possible<br />

to outline the thin-walled cooling<br />

8 Casting Plant & Technology 1/2<strong>01</strong>5