Maintworld 3/2017

In this issue: Using Technology and Innovation to Manage Mega-Maintenance Challenges Identify the Root Cause of a Misalignment Condition Elements of a Good Preventive Maintenance Program

In this issue:

Using Technology and Innovation to Manage Mega-Maintenance Challenges

Identify the Root Cause of a Misalignment Condition

Elements of a Good Preventive Maintenance Program

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RELIABILITY<br />

is a win-win, change will happen and<br />

the improvements will be sustained.<br />

If not, frustration will continue.<br />

Are you willing to do that?<br />

Upon making that suggestion I could<br />

again see some doubt. Technical<br />

people are not always great with the<br />

“touchy-feely” stuff. We may be interested<br />

in technical solutions, and<br />

we might want to dictate how things<br />

should be done and maybe even take<br />

credit for the change. That motivates<br />

you, but it doesn’t motivate the other<br />

person. So this is a tough decision to<br />

make. What’s most important, you<br />

or the people who are working with?<br />

What’s most important, you or the<br />

success of the reliability improvement<br />

program (i.e. the success of the<br />

organization)?<br />

Conclusion<br />

With strong leadership, reliability<br />

can be improved, and every employee<br />

will benefit. It is very difficult to force<br />

change, but when people are motivated<br />

anything is possible.<br />

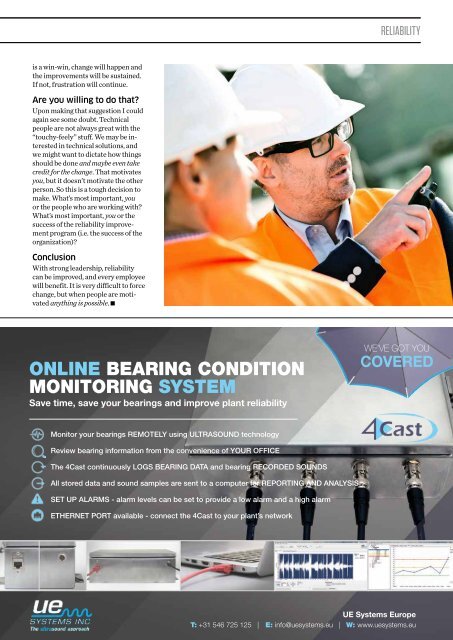

ONLINE BEARING CONDITION<br />

MONITORING SYSTEM<br />

Save time, save your bearings and improve plant reliability<br />

WE’VE GOT YOU<br />

COVERED<br />

Monitor your bearings REMOTELY using ULTRASOUND technology<br />

Review bearing information from the convenience of YOUR OFFICE<br />

The 4Cast continuously LOGS BEARING DATA and bearing RECORDED SOUNDS<br />

All stored data and sound samples are sent to a computer for REPORTING AND ANALYSIS<br />

SET UP ALARMS - alarm levels can be set to provide a low alarm and a high alarm<br />

ETHERNET PORT available - connect the 4Cast to your plant’s network<br />

UE Systems Europe<br />

T: +31 546 725 125 | E: info@uesystems.eu | W: www.uesystems.eu