HELP Hydrocarbon Exploration and Licensing Policy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tamil Research Institution (TRI)<br />

5450 metres with maximum mud weight of 2.05 g.cc <strong>and</strong> reservoir<br />

temperature was more than 450 deg F. Due care was taken to ensure<br />

safe operations <strong>and</strong> safety of the well. Clear fluid comprising Calcium<br />

Bromide <strong>and</strong> Zinc Bromide was used during testing for desired<br />

pressure transmission for DST operation of different downhole<br />

valves. This technology enabled us to give stage wise cycling of the<br />

recirculation valves in the DST string, thus different predetermined<br />

drawdown could be given for activation. This also eliminated the use<br />

of CTU in 15 K well for repeated activation.<br />

n. Some of the new technologies for HPHT fields: Ceramic S<strong>and</strong> Screens<br />

having exceptional resistance to erosion/ corrosion <strong>and</strong> outst<strong>and</strong>ing<br />

hardness. It is touted to be useful in offshore wells <strong>and</strong> HPHT wells.<br />

Corrosion resistant alloys for casing liners <strong>and</strong> tubings. HPHT FB-3<br />

Retainer Production Packer-Used in more than 5 wells in ONGC<br />

Mumbai High <strong>and</strong> Rajahmundry Assets.<br />

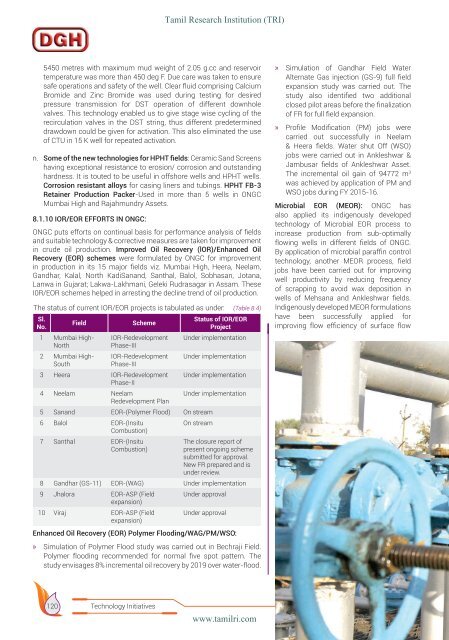

8.1.10 IOR/EOR EFFORTS IN ONGC:<br />

ONGC puts efforts on continual basis for performance analysis of fields<br />

<strong>and</strong> suitable technology & corrective measures are taken for improvement<br />

in crude oil production. Improved Oil Recovery (lOR)/Enhanced Oil<br />

Recovery (EOR) schemes were formulated by ONGC for improvement<br />

in production in its 15 major fields viz. Mumbai High, Heera, Neelam,<br />

G<strong>and</strong>har, Kalal, North KadiSan<strong>and</strong>, Santhal, Balol, Sobhasan, Jotana,<br />

Lanwa in Gujarat; Lakwa-Lakhmani, Geleki Rudrasagar in Assam. These<br />

I0R/EOR schemes helped in arresting the decline trend of oil production.<br />

The status of current IOR/EOR projects is tabulated as under: (Table 8.4)<br />

Sl.<br />

No.<br />

Field<br />

1 Mumbai High-<br />

North<br />

2 Mumbai High-<br />

South<br />

Scheme<br />

IOR-Redevelopment<br />

Phase-III<br />

IOR-Redevelopment<br />

Phase-III<br />

3 Heera IOR-Redevelopment<br />

Phase-II<br />

4 Neelam Neelam<br />

Redevelopment Plan<br />

5 San<strong>and</strong> EOR-(Polymer Flood) On stream<br />

6 Balol EOR-(Insitu<br />

Combustion)<br />

7 Santhal EOR-(Insitu<br />

Combustion)<br />

Status of IOR/EOR<br />

Project<br />

Under implementation<br />

Under implementation<br />

Under implementation<br />

Under implementation<br />

On stream<br />

The closure report of<br />

present ongoing scheme<br />

submitted for approval.<br />

New FR prepared <strong>and</strong> is<br />

under review.<br />

8 G<strong>and</strong>har (GS-11) EOR-(WAG) Under implementation<br />

9 Jhalora EOR-ASP (Field<br />

expansion)<br />

10 Viraj EOR-ASP (Field<br />

expansion)<br />

Under approval<br />

Under approval<br />

Enhanced Oil Recovery (EOR) Polymer Flooding/WAG/PM/WSO:<br />

»»<br />

Simulation of Polymer Flood study was carried out in Bechraji Field.<br />

Polymer flooding recommended for normal five spot pattern. The<br />

study envisages 8% incremental oil recovery by 2019 over water-flood.<br />

»»<br />

Simulation of G<strong>and</strong>har Field Water<br />

Alternate Gas injection (GS-9) full field<br />

expansion study was carried out. The<br />

study also identified two additional<br />

closed pilot areas before the finalization<br />

of FR for full field expansion.<br />

»»<br />

Profile Modification (PM) jobs were<br />

carried out successfully in Neelam<br />

& Heera fields. Water shut Off (WSO)<br />

jobs were carried out in Ankleshwar &<br />

Jambusar fields of Ankleshwar Asset.<br />

The incremental oil gain of 94772 m 3<br />

was achieved by application of PM <strong>and</strong><br />

WSO jobs during FY 2015-16.<br />

Microbial EOR (MEOR): ONGC has<br />

also applied its indigenously developed<br />

technology of Microbial EOR process to<br />

increase production from sub-optimally<br />

flowing wells in different fields of ONGC.<br />

By application of microbial paraffin control<br />

technology, another MEOR process, field<br />

jobs have been carried out for improving<br />

well productivity by reducing frequency<br />

of scrapping to avoid wax deposition in<br />

wells of Mehsana <strong>and</strong> Ankleshwar fields.<br />

Indigenously developed MEOR formulations<br />

have been successfully applied for<br />

improving flow efficiency of surface flow<br />

120<br />

Technology Initiatives<br />

www.tamilri.com