-TechManual_SRK05,09,12CR-S,CRR-S,CRP-S

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

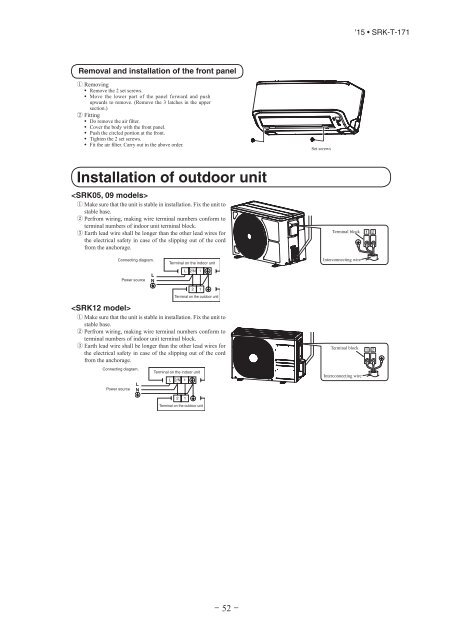

Removal and installation of the front panel<br />

Removing<br />

Remove the 2 set screws.<br />

Move the lower part of the panel forward and push<br />

upwards to remove. (Remove the 3 latches in the upper<br />

section.)<br />

Fitting<br />

Do remove the air filter.<br />

Cover the body with the front panel.<br />

Push the circled portion at the front.<br />

Tighten the 2 set screws.<br />

Fit the air filter. Carry out in the above order.<br />

Installation of outdoor unit<br />

<br />

Make sure that the unit is stable in installation. Fix the unit to<br />

stable base.<br />

Perfrom wiring, making wire terminal numbers conform to<br />

terminal numbers of indoor unit terminal block.<br />

Earth lead wire shall be longer than the other lead wires for<br />

the electrical safety in case of the slipping out of the cord<br />

from the anchorage.<br />

Connecting diagram.<br />

<br />

Make sure that the unit is stable in installation. Fix the unit to<br />

stable base.<br />

Perfrom wiring, making wire terminal numbers conform to<br />

terminal numbers of indoor unit terminal block.<br />

Earth lead wire shall be longer than the other lead wires for<br />

the electrical safety in case of the slipping out of the cord<br />

from the anchorage.<br />

Connecting diagram.<br />

Power source<br />

Power source<br />

L<br />

N<br />

L<br />

N<br />

Terminal on the indoor unit<br />

Terminal on the indoor unit<br />

L 2/N 1<br />

2<br />

L 2/N 1<br />

Terminal on the outdoor unit<br />

1<br />

2<br />

Terminal on the outdoor unit<br />

1<br />

'15 • SRK-T-171<br />

Set screws<br />

Terminal block 1 2<br />

Interconnecting wire<br />

Terminal block<br />

1 2<br />

Interconnecting wire<br />

– 32–<br />

RMA012A080_<strong>09</strong>1-<strong>09</strong>3_EN.indb 32 05/11/2014 11:50:41