Biennial Report 2016/2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Selected Results<br />

Novel Setup for Investigation of Ion Energy and Ion Mass Selective<br />

Hyperthermal Ion-Beam Assisted Deposition Processes<br />

J.W. Gerlach, P. Schumacher, M. Mensing, B. Rauschenbach<br />

in collaboration with<br />

S. Rauschenbach, MPI-FKF Stuttgart / University of Oxford, UK, I. Cermak, CGC Instruments, Chemnitz<br />

Ion-beam assisted deposition (IBAD) is a highly<br />

effective hybrid physical thin film deposition<br />

technique which on the one hand offers the<br />

opportunity to investigate fundamental processes<br />

involved in ion-assisted film growth and on the<br />

other hand provides manifold possibilities to<br />

intentionally modify the properties of the prepared<br />

thin films [1]. The technique is characterized by<br />

simultaneous irradiation of the growing thin film<br />

with energetic ions during deposition with the aim<br />

to significantly influence the growth processes<br />

themselves. In contrast to other physical<br />

deposition methods like e.g. magnetron sputtering<br />

or pulsed laser deposition, IBAD is mainly defined<br />

by the separability of the involved material fluxes,<br />

which are directed towards the sample, as well as<br />

by the possibility to adjust the parameters vapor<br />

flux and ion flux highly accurate, the latter<br />

generated in form of a broad ion beam. As for<br />

nitrogen ion beams however, nitrogen plasma<br />

based ion-beam sources counteract the demand<br />

to choose the ion-beam parameters as freely as<br />

possible, because (i) the resulting ion beam<br />

consists of a blend of both molecular (N 2 + ) and<br />

atomic nitrogen ions (N + ) and (ii) both species can<br />

possess differing kinetic energy distributions.<br />

Particularly in the case of hyperthermal ion<br />

energies ranging from several 10 eV to a few<br />

100 eV this creates great difficulties to input the<br />

ion energy into the growing film surface in a welldefined<br />

and well-controlled way. Therefore, in<br />

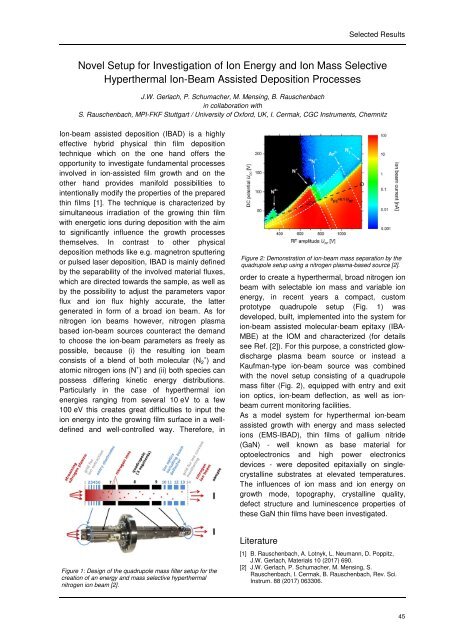

Figure 2: Demonstration of ion-beam mass separation by the<br />

quadrupole setup using a nitrogen plasma-based source [2].<br />

order to create a hyperthermal, broad nitrogen ion<br />

beam with selectable ion mass and variable ion<br />

energy, in recent years a compact, custom<br />

prototype quadrupole setup (Fig. 1) was<br />

developed, built, implemented into the system for<br />

ion-beam assisted molecular-beam epitaxy (IBA-<br />

MBE) at the IOM and characterized (for details<br />

see Ref. [2]). For this purpose, a constricted glowdischarge<br />

plasma beam source or instead a<br />

Kaufman-type ion-beam source was combined<br />

with the novel setup consisting of a quadrupole<br />

mass filter (Fig. 2), equipped with entry and exit<br />

ion optics, ion-beam deflection, as well as ionbeam<br />

current monitoring facilities.<br />

As a model system for hyperthermal ion-beam<br />

assisted growth with energy and mass selected<br />

ions (EMS-IBAD), thin films of gallium nitride<br />

(GaN) - well known as base material for<br />

optoelectronics and high power electronics<br />

devices - were deposited epitaxially on singlecrystalline<br />

substrates at elevated temperatures.<br />

The influences of ion mass and ion energy on<br />

growth mode, topography, crystalline quality,<br />

defect structure and luminescence properties of<br />

these GaN thin films have been investigated.<br />

Figure 1: Design of the quadrupole mass filter setup for the<br />

creation of an energy and mass selective hyperthermal<br />

nitrogen ion beam [2].<br />

Literature<br />

[1] B. Rauschenbach, A. Lotnyk, L. Neumann, D. Poppitz,<br />

J.W. Gerlach, Materials 10 (<strong>2017</strong>) 690.<br />

[2] J.W. Gerlach, P. Schumacher, M. Mensing, S.<br />

Rauschenbach, I. Cermak, B. Rauschenbach, Rev. Sci.<br />

Instrum. 88 (<strong>2017</strong>) 063306.<br />

45