Biennial Report 2016/2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Selected Results<br />

Near-Infrared Chemical Imaging of Functional Finishes on Textiles<br />

O. Daikos, G. Mirschel, T. Scherzer<br />

The permanently increasing demands on product<br />

quality and homogeneity pose a continuous<br />

challenge to measuring and process control<br />

technologies that are indispensable to meet these<br />

requirements. In case of the production or processing<br />

of web-like or planar materials such as<br />

paper, polymer films, textiles, plates, sheets etc.,<br />

the homogeneity of the material and the spatial<br />

distribution of quantitative values of parameters<br />

resulting from finishing steps such as coating,<br />

impregnation, varnishing, lamination, etc. become<br />

more and more important. The advent of large<br />

hyperspectral cameras working in the NIR range<br />

broadened the potential of analytical methods for<br />

process control considerably. In the framework of<br />

this research area, new approaches for<br />

monitoring of technical processes are developed<br />

[1]. This contribution is focused on applications of<br />

NIR chemical imaging in textile surface finishing<br />

technology.<br />

Agents applied as finishes provide the textile<br />

fabric with special functional features. For<br />

example, such formulations include stiffening<br />

agents, optical brighteners, flame retardants,<br />

hydrophilic or hydrophobic agents, anti-static, and<br />

anti-microbial finishes etc. Depending on the<br />

specific substrate, agent, and intended application<br />

they may be applied with application weights in<br />

the range from less than 1 g/m² to several tens of<br />

g/m². The rather low application weight of some<br />

finishes makes very high demands on the<br />

sensitivity of the detection method.<br />

Figure 1: Chemical image of a polyester fabric provided with<br />

different amounts of a flame retardant. Gravimetric<br />

application weights: 15.5 g/m² (left) and 26 g/m² (right).<br />

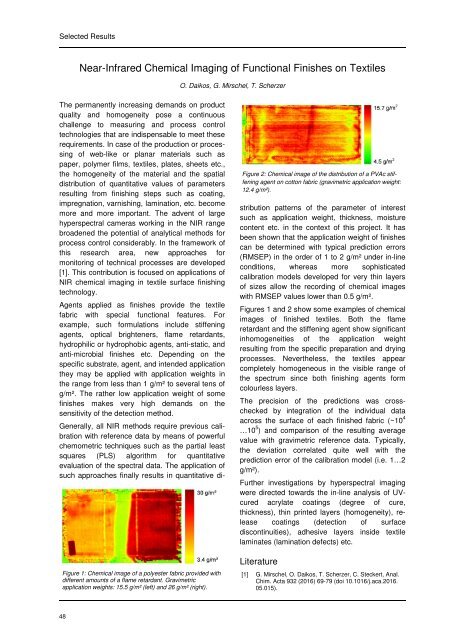

Figure 2: Chemical image of the distribution of a PVAc stiffening<br />

agent on cotton fabric (gravimetric application weight:<br />

12.4 g/m²).<br />

Generally, all NIR methods require previous calibration<br />

with reference data by means of powerful<br />

chemometric techniques such as the partial least<br />

squares (PLS) algorithm for quantitative<br />

evaluation of the spectral data. The application of<br />

such approaches finally results in quantitative distribution<br />

patterns of the parameter of interest<br />

such as application weight, thickness, moisture<br />

content etc. in the context of this project. It has<br />

been shown that the application weight of finishes<br />

can be determined with typical prediction errors<br />

(RMSEP) in the order of 1 to 2 g/m² under in-line<br />

conditions, whereas more sophisticated<br />

calibration models developed for very thin layers<br />

of sizes allow the recording of chemical images<br />

with RMSEP values lower than 0.5 g/m².<br />

Figures 1 and 2 show some examples of chemical<br />

images of finished textiles. Both the flame<br />

retardant and the stiffening agent show significant<br />

inhomogeneities of the application weight<br />

resulting from the specific preparation and drying<br />

processes. Nevertheless, the textiles appear<br />

completely homogeneous in the visible range of<br />

the spectrum since both finishing agents form<br />

colourless layers.<br />

The precision of the predictions was crosschecked<br />

by integration of the individual data<br />

across the surface of each finished fabric (~10 4<br />

…10 5 ) and comparison of the resulting average<br />

value with gravimetric reference data. Typically,<br />

the deviation correlated quite well with the<br />

prediction error of the calibration model (i.e. 1…2<br />

g/m²).<br />

Further investigations by hyperspectral imaging<br />

were directed towards the in-line analysis of UVcured<br />

acrylate coatings (degree of cure,<br />

thickness), thin printed layers (homogeneity), release<br />

coatings (detection of surface<br />

discontinuities), adhesive layers inside textile<br />

laminates (lamination defects) etc.<br />

Literature<br />

[1] G. Mirschel, O. Daikos, T. Scherzer, C. Steckert, Anal.<br />

Chim. Acta 932 (<strong>2016</strong>) 69-79 (doi 10.1016/j.aca.<strong>2016</strong>.<br />

05.015).<br />

48