Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

D and DL Annular Blowout Preventers<br />

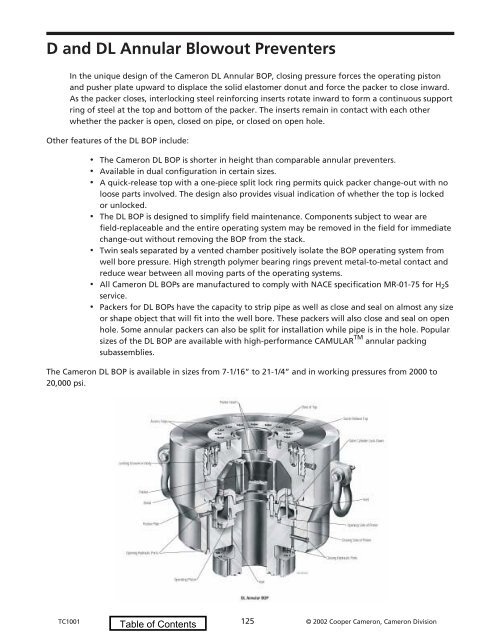

In the unique design of the Cameron DL Annular BOP, closing pressure forces the operating piston<br />

and pusher plate upward to displace the solid elastomer donut and force the packer to close inward.<br />

As the packer closes, interlocking steel reinforcing inserts rotate inward to form a continuous support<br />

ring of steel at the top and bottom of the packer. The inserts remain in contact with each other<br />

whether the packer is open, closed on pipe, or closed on open hole.<br />

Other features of the DL BOP include:<br />

• The Cameron DL BOP is shorter in height than comparable annular preventers.<br />

• Available in dual configuration in certain sizes.<br />

• A quick-release top with a one-piece split lock ring permits quick packer change-out with no<br />

loose parts involved. The design also provides visual indication of whether the top is locked<br />

or unlocked.<br />

• The DL BOP is designed to simplify field maintenance. Components subject to wear are<br />

field-replaceable and the entire operating system may be removed in the field for immediate<br />

change-out without removing the BOP from the stack.<br />

• Twin seals separated by a vented chamber positively isolate the BOP operating system from<br />

well bore pressure. High strength polymer bearing rings prevent metal-to-metal contact and<br />

reduce wear between all moving parts of the operating systems.<br />

• All Cameron DL BOPs are manufactured to comply with NACE specification MR-01-75 for H 2 S<br />

service.<br />

• Packers for DL BOPs have the capacity to strip pipe as well as close and seal on almost any size<br />

or shape object that will fit into the well bore. These packers will also close and seal on open<br />

hole. Some annular packers can also be split for installation while pipe is in the hole. Popular<br />

sizes of the DL BOP are available with high-performance CAMULAR TM annular packing<br />

subassemblies.<br />

The Cameron DL BOP is available in sizes from 7-1/16” to 21-1/4” and in working pressures from 2000 to<br />

20,000 psi.<br />

TC1001 125 © <strong>2002</strong> Cooper Cameron, Cameron Division