WORLD OF INDUSTRIES 06/2018 (RU)

WORLD OF INDUSTRIES 06/2018 (RU)

WORLD OF INDUSTRIES 06/2018 (RU)

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

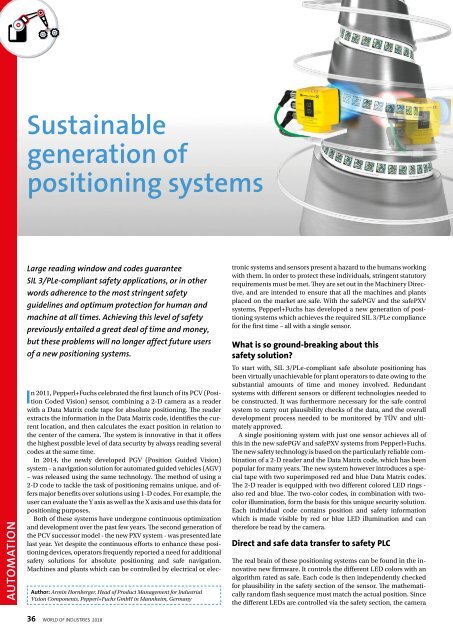

Sustainable<br />

generation of<br />

positioning systems<br />

AUTOMATION<br />

Large reading window and codes guarantee<br />

SIL 3/PLe-compliant safety applications, or in other<br />

words adherence to the most stringent safety<br />

guidelines and optimum protection for human and<br />

machine at all times. Achieving this level of safety<br />

previously entailed a great deal of time and money,<br />

but these problems will no longer affect future users<br />

of a new positioning systems.<br />

I<br />

n 2011, Pepperl+Fuchs celebrated the first launch of its PCV (Position<br />

Coded Vision) sensor, combining a 2-D camera as a reader<br />

with a Data Matrix code tape for absolute positioning. The reader<br />

extracts the information in the Data Matrix code, identifies the current<br />

location, and then calculates the exact position in relation to<br />

the center of the camera. The system is innovative in that it offers<br />

the highest possible level of data security by always reading several<br />

codes at the same time.<br />

In 2014, the newly developed PGV (Position Guided Vision)<br />

system – a navigation solution for automated guided vehicles (AGV)<br />

– was released using the same technology. The method of using a<br />

2-D code to tackle the task of positioning remains unique, and offers<br />

major benefits over solutions using 1-D codes. For example, the<br />

user can evaluate the Y axis as well as the X axis and use this data for<br />

positioning purposes.<br />

Both of these systems have undergone continuous optimization<br />

and development over the past few years. The second generation of<br />

the PCV successor model - the new PXV system - was presented late<br />

last year. Yet despite the continuous efforts to enhance these positioning<br />

devices, operators frequently reported a need for additional<br />

safety solutions for absolute positioning and safe navigation.<br />

Machines and plants which can be controlled by electrical or elec-<br />

Author: Armin Hornberger, Head of Product Management for Industrial<br />

Vision Components, Pepperl+Fuchs GmbH in Mannheim, Germany<br />

tronic systems and sensors present a hazard to the humans working<br />

with them. In order to protect these individuals, stringent statutory<br />

requirements must be met. They are set out in the Machinery Directive,<br />

and are intended to ensure that all the machines and plants<br />

placed on the market are safe. With the safePGV and the safePXV<br />

systems, Pepperl+Fuchs has developed a new generation of positioning<br />

systems which achieves the required SIL 3/PLe compliance<br />

for the first time – all with a single sensor.<br />

What is so ground-breaking about this<br />

safety solution?<br />

To start with, SIL 3/PLe-compliant safe absolute positioning has<br />

been virtually unachievable for plant operators to date owing to the<br />

substantial amounts of time and money involved. Redundant<br />

systems with different sensors or different technologies needed to<br />

be constructed. It was furthermore necessary for the safe control<br />

system to carry out plausibility checks of the data, and the overall<br />

development process needed to be monitored by TÜV and ultimately<br />

approved.<br />

A single positioning system with just one sensor achieves all of<br />

this in the new safePGV and safePXV systems from Pepperl+Fuchs.<br />

The new safety technology is based on the particularly reliable combination<br />

of a 2-D reader and the Data Matrix code, which has been<br />

popular for many years. The new system however introduces a special<br />

tape with two superimposed red and blue Data Matrix codes.<br />

The 2-D reader is equipped with two different colored LED rings -<br />

also red and blue. The two-color codes, in combination with twocolor<br />

illumination, form the basis for this unique security solution.<br />

Each individual code contains position and safety information<br />

which is made visible by red or blue LED illumination and can<br />

therefore be read by the camera.<br />

Direct and safe data transfer to safety PLC<br />

The real brain of these positioning systems can be found in the innovative<br />

new firmware. It controls the different LED colors with an<br />

algorithm rated as safe. Each code is then independently checked<br />

for plausibility in the safety section of the sensor. The mathematically<br />

random flash sequence must match the actual position. Since<br />

the different LEDs are controlled via the safety section, the camera<br />

36 <strong>WORLD</strong> <strong>OF</strong> <strong>INDUSTRIES</strong> <strong>2018</strong>