The Garage 282

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NEWS 08<br />

Cut to the finish<br />

line faster with<br />

Mirka Iridium<br />

A<br />

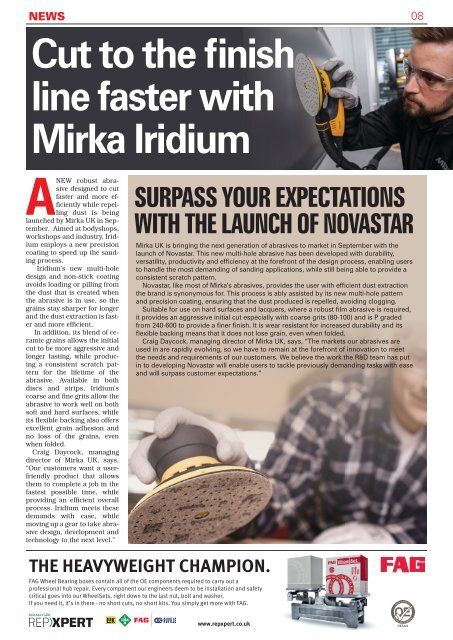

NEW robust abrasive<br />

designed to cut<br />

faster and more efficiently<br />

while repelling<br />

dust is being<br />

launched by Mirka UK in September.<br />

Aimed at bodyshops,<br />

workshops and industry, Iridium<br />

employs a new precision<br />

coating to speed up the sanding<br />

process.<br />

Iridium’s new multi-hole<br />

design and non-stick coating<br />

avoids loading or pilling from<br />

the dust that is created when<br />

the abrasive is in use, so the<br />

grains stay sharper for longer<br />

and the dust extraction is faster<br />

and more efficient.<br />

In addition, its blend of ceramic<br />

grains allows the initial<br />

cut to be more aggressive and<br />

longer lasting, while producing<br />

a consistent scratch pattern<br />

for the lifetime of the<br />

abrasive. Available in both<br />

discs and strips, Iridium’s<br />

coarse and fine grits allow the<br />

abrasive to work well on both<br />

soft and hard surfaces, while<br />

its flexible backing also offers<br />

excellent grain adhesion and<br />

no loss of the grains, even<br />

when folded.<br />

Craig Daycock, managing<br />

director of Mirka UK, says,<br />

“Our customers want a userfriendly<br />

product that allows<br />

them to complete a job in the<br />

fastest possible time, while<br />

providing an efficient overall<br />

process. Iridium meets these<br />

demands with ease, while<br />

moving up a gear to take abrasive<br />

design, development and<br />

technology to the next level.”<br />

SURPASS YOUR EXPECTATIONS<br />

WITH THE LAUNCH OF NOVASTAR<br />

Mirka UK is bringing the next generation of abrasives to market in September with the<br />

launch of Novastar. This new multi-hole abrasive has been developed with durability,<br />

versatility, productivity and efficiency at the forefront of the design process, enabling users<br />

to handle the most demanding of sanding applications, while still being able to provide a<br />

consistent scratch pattern.<br />

Novastar, like most of Mirka’s abrasives, provides the user with efficient dust extraction<br />

the brand is synonymous for. This process is ably assisted by its new multi-hole pattern<br />

and precision coating, ensuring that the dust produced is repelled, avoiding clogging.<br />

Suitable for use on hard surfaces and lacquers, where a robust film abrasive is required,<br />

it provides an aggressive initial cut especially with coarse grits (80-100) and is P graded<br />

from 240-600 to provide a finer finish. It is wear resistant for increased durability and its<br />

flexible backing means that it does not lose grain, even when folded.<br />

Craig Daycock, managing director of Mirka UK, says, “<strong>The</strong> markets our abrasives are<br />

used in are rapidly evolving, so we have to remain at the forefront of innovation to meet<br />

the needs and requirements of our customers. We believe the work the R&D team has put<br />

in to developing Novastar will enable users to tackle previously demanding tasks with ease<br />

and will surpass customer expectations.”<br />

THE HEAVYWEIGHT CHAMPION.<br />

FAG Wheel Bearing boxes contain all of the OE components required to carry out a<br />

professional hub repair. Every component our engineers deem to be installation and safety<br />

critical goes into our WheelSets, right down to the last nut, bolt and washer.<br />

If you need it, it’s in there - no short cuts, no short kits. You simply get more with FAG.<br />

www.repxpert.co.uk<br />

8 News.indd 1 14/09/2018 09:54