Boker Knifestyle | EN Edition 2018 / 2019

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

36 CONSTRUCTION OF A KITCH<strong>EN</strong> KNIFE<br />

CONSTRUCTION METHODS & BLADE JOINTS<br />

The knife has been an essential universal tool for more than 2.4 million years. Knives are available in a wide variety of shapes and designs for<br />

almost any purpose. As a tool, kitchen implement, decorative object or collector’s item – people value the advantages of these sharp tools<br />

in every kitchen. The construction possibilities for a kitchen knife are almost as varied as the possible uses – from cutting fresh bread to<br />

carving a beef tenderloin or filleting fresh fish. At the <strong>Boker</strong> Manufactory, we use three different blade and handle joint designs, depending<br />

on the knife series.<br />

Each design has its own tradition and purpose, and offers different advantages in terms of production, handling and use. Despite all<br />

differences, these designs of <strong>Boker</strong> kitchen knives have one thing in common - they are all excellent and superior kitchen knives that you<br />

will never want to put down. Depending on your individual and personal preferences in terms of design, weight, ergonomics and balance,<br />

you are sure to find the right knife in our collection.<br />

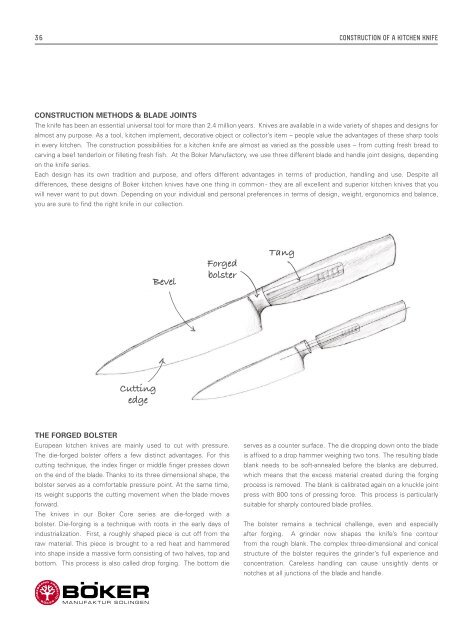

Bevel<br />

Forged<br />

bolster<br />

Tang<br />

Cutting<br />

edge<br />

THE FORGED BOLSTER<br />

European kitchen knives are mainly used to cut with pressure.<br />

The die-forged bolster offers a few distinct advantages. For this<br />

cutting technique, the index finger or middle finger presses down<br />

on the end of the blade. Thanks to its three dimensional shape, the<br />

bolster serves as a comfortable pressure point. At the same time,<br />

its weight supports the cutting movement when the blade moves<br />

forward.<br />

The knives in our <strong>Boker</strong> Core series are die-forged with a<br />

bolster. Die-forging is a technique with roots in the early days of<br />

industrialization. First, a roughly shaped piece is cut off from the<br />

raw material. This piece is brought to a red heat and hammered<br />

into shape inside a massive form consisting of two halves, top and<br />

bottom. This process is also called drop forging. The bottom die<br />

serves as a counter surface. The die dropping down onto the blade<br />

is affixed to a drop hammer weighing two tons. The resulting blade<br />

blank needs to be soft-annealed before the blanks are deburred,<br />

which means that the excess material created during the forging<br />

process is removed. The blank is calibrated again on a knuckle joint<br />

press with 800 tons of pressing force. This process is particularly<br />

suitable for sharply contoured blade profiles.<br />

The bolster remains a technical challenge, even and especially<br />

after forging. A grinder now shapes the knife’s fine contour<br />

from the rough blank. The complex three-dimensional and conical<br />

structure of the bolster requires the grinder’s full experience and<br />

concentration. Careless handling can cause unsightly dents or<br />

notches at all junctions of the blade and handle.