Siouxland Magazine - Volume 2 Issue 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

was purchased for the construction of the Veterans<br />

Memorial Bridge in 1978. Their move to 501 W 9th in<br />

South Sioux City continues to be the current location.<br />

By this time, Harold’s son, Terry McArthur, had become<br />

an employee of the business – beginning the first<br />

generational transition. When Harold died in 1983<br />

the business was 51% owned by Terry. Terry would<br />

eventually buy out his brothers. Terry has two sons,<br />

Dave and Bill, who grew up around the business. Dave<br />

remembers he and his brother playing on the dirt piles<br />

and writing their names in the concrete as the business<br />

was moved and buildings went up. “We played hide<br />

and seek in the shop a lot as kids.” Dave recalls, “This<br />

is where I grew up. “ By 1986, Dave had begun working<br />

part-time in the shop on weekends and in the summer,<br />

learning first-hand what the business entailed by<br />

working alongside his father and others.<br />

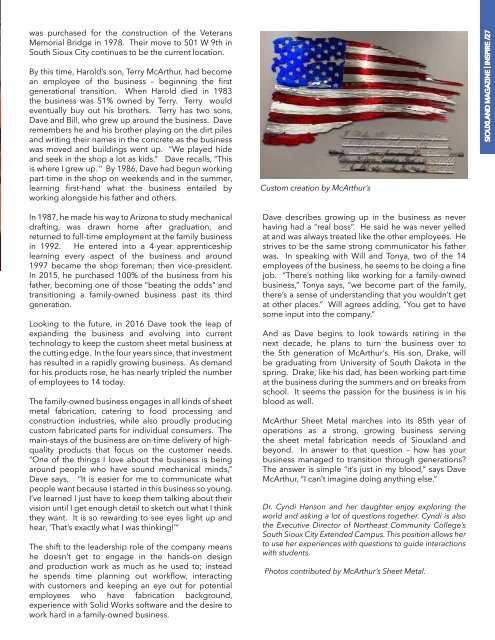

Custom creation by McArthur’s<br />

<strong>Siouxland</strong> <strong>Magazine</strong> | Inspire /27<br />

In 1987, he made his way to Arizona to study mechanical<br />

drafting, was drawn home after graduation, and<br />

returned to full-time employment at the family business<br />

in 1992. He entered into a 4-year apprenticeship<br />

learning every aspect of the business and around<br />

1997 became the shop foreman; then vice-president.<br />

In 2015, he purchased 100% of the business from his<br />

father, becoming one of those “beating the odds” and<br />

transitioning a family-owned business past its third<br />

generation.<br />

Looking to the future, in 2016 Dave took the leap of<br />

expanding the business and evolving into current<br />

technology to keep the custom sheet metal business at<br />

the cutting edge. In the four years since, that investment<br />

has resulted in a rapidly growing business. As demand<br />

for his products rose, he has nearly tripled the number<br />

of employees to 14 today.<br />

The family-owned business engages in all kinds of sheet<br />

metal fabrication, catering to food processing and<br />

construction industries, while also proudly producing<br />

custom fabricated parts for individual consumers. The<br />

main-stays of the business are on-time delivery of highquality<br />

products that focus on the customer needs.<br />

“One of the things I love about the business is being<br />

around people who have sound mechanical minds,”<br />

Dave says, “It is easier for me to communicate what<br />

people want because I started in this business so young.<br />

I’ve learned I just have to keep them talking about their<br />

vision until I get enough detail to sketch out what I think<br />

they want. It is so rewarding to see eyes light up and<br />

hear, ‘That’s exactly what I was thinking!’”<br />

The shift to the leadership role of the company means<br />

he doesn’t get to engage in the hands-on design<br />

and production work as much as he used to; instead<br />

he spends time planning out workflow, interacting<br />

with customers and keeping an eye out for potential<br />

employees who have fabrication background,<br />

experience with Solid Works software and the desire to<br />

work hard in a family-owned business.<br />

Dave describes growing up in the business as never<br />

having had a “real boss”. He said he was never yelled<br />

at and was always treated like the other employees. He<br />

strives to be the same strong communicator his father<br />

was. In speaking with Will and Tonya, two of the 14<br />

employees of the business, he seems to be doing a fine<br />

job. “There’s nothing like working for a family-owned<br />

business,” Tonya says, “we become part of the family,<br />

there’s a sense of understanding that you wouldn’t get<br />

at other places.” Will agrees adding, “You get to have<br />

some input into the company.”<br />

And as Dave begins to look towards retiring in the<br />

next decade, he plans to turn the business over to<br />

the 5th generation of McArthur’s. His son, Drake, will<br />

be graduating from University of South Dakota in the<br />

spring. Drake, like his dad, has been working part-time<br />

at the business during the summers and on breaks from<br />

school. It seems the passion for the business is in his<br />

blood as well.<br />

McArthur Sheet Metal marches into its 85th year of<br />

operations as a strong, growing business serving<br />

the sheet metal fabrication needs of <strong>Siouxland</strong> and<br />

beyond. In answer to that question – how has your<br />

business managed to transition through generations?<br />

The answer is simple “it’s just in my blood,” says Dave<br />

McArthur, “I can’t imagine doing anything else.”<br />

Dr. Cyndi Hanson and her daughter enjoy exploring the<br />

world and asking a lot of questions together. Cyndi is also<br />

the Executive Director of Northeast Community College’s<br />

South Sioux City Extended Campus. This position allows her<br />

to use her experiences with questions to guide interactions<br />

with students.<br />

Photos contributed by McArthur’s Sheet Metal.