Inside NIRMA Spring 2020 FINAL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Issue # 07, <strong>Spring</strong> <strong>2020</strong><br />

<strong>Inside</strong><br />

Leading the way in Nuclear Information and Records Management<br />

magazine<br />

Visit us at: <strong>NIRMA</strong>.org<br />

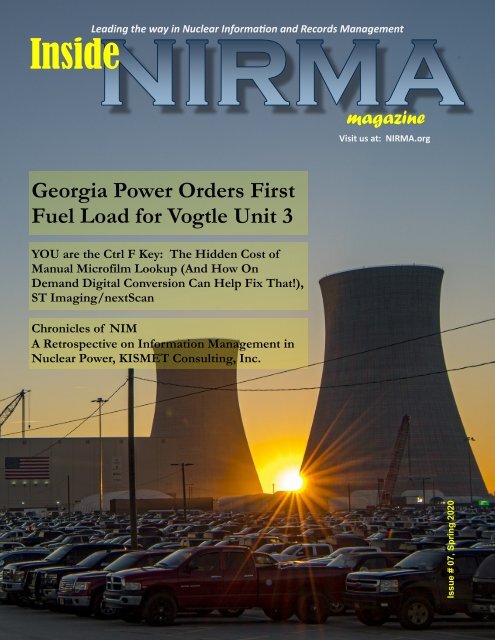

Georgia Power Orders First<br />

Fuel Load for Vogtle Unit 3<br />

YOU are the Ctrl F Key: The Hidden Cost of<br />

Manual Microfilm Lookup (And How On<br />

Demand Digital Conversion Can Help Fix That!),<br />

ST Imaging/nextScan<br />

Chronicles of NIM<br />

A Retrospective on Information Management in<br />

Nuclear Power, KISMET Consulting, Inc.

Contents<br />

<strong>Spring</strong> <strong>2020</strong><br />

4<br />

7<br />

10<br />

Georgia Power Orders First Fuel Load for Vogtle Unit 3<br />

YOU are the Ctrl F Key: The Hidden Cost of Manual<br />

Microfilm Lookup (And How On Demand Digital<br />

Conversion Can Help Fix That!)<br />

By Arijana Dizdarevic, Sales & Marketing Coordinator, STimaging / nextScan<br />

Chronicles of NIM: A Retrospective on Information<br />

Management in Nuclear Power<br />

By Eugene Yang, Kismet Consulting<br />

12<br />

14<br />

<strong>2020</strong> <strong>NIRMA</strong> Conference Keynote Speakers<br />

<strong>NIRMA</strong> Transforming the <strong>2020</strong> Conference<br />

By Janice Hoerber, Vice President of <strong>NIRMA</strong><br />

Front and Back Cover Photos: Georgia Power Company Plant:<br />

Front Cover (left) Plants Vogtle Units 1-4.<br />

Back Cover (right) Vogtle Unit 3 Reactor Vessel Cavity.<br />

2 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

CONTENTS<br />

in every issue<br />

FROM YOUR PRESIDENT—9<br />

SECRETARY NEWS—15<br />

TREASURER REPORT—16<br />

PDBU NEWS—16<br />

M&MBU NEWS—17<br />

NOMINATING COMMITTEE—17<br />

INDUSTRY NEWS—18<br />

Editors<br />

Neal and Sandra Miller<br />

DevereauxInc@outlook.com<br />

A Note from the Editors<br />

Help us Grow our<br />

Social Media Presence!<br />

In 2019, <strong>NIRMA</strong> took steps to further establish itself on<br />

social media, this included adding a Twitter account and<br />

taking the opportunity to communicate more frequently via<br />

Facebook and LinkedIn. With Facebook and Twitter alone,<br />

we were able to add nearly 400 followers and reach more<br />

than 25,000 people.<br />

While we were happy with those results, we aren’t<br />

through and to quote an old Carpenters song “We’ve Only<br />

Just Begun.” The <strong>NIRMA</strong> Board of Directors established<br />

“Increase <strong>NIRMA</strong>’s awareness by continued use of the<br />

<strong>NIRMA</strong> website and social media” as one of its key goals<br />

for <strong>2020</strong>. In pursuing this goal, we believe it will help us<br />

grow our membership and increase vendor participation.<br />

And by continuing to get bigger and better, it will allow us<br />

to increase the value we are able to provide our<br />

membership.<br />

Now the big question. How can you help? If you<br />

haven’t already, take a moment to like and follow us on<br />

Facebook and follow us on Twitter, LinkedIn and our newly<br />

established Instagram account. To take things to the next<br />

level, when you see a post from us, comment on it and<br />

share it with others.<br />

To help get you started, the links to each of our social<br />

media platforms are within the icons below. Please take a<br />

moment to follow us on Twitter and Instagram, like us on<br />

Facebook, and connect with us on LinkedIn.<br />

Thank you for your support!<br />

Neal & Sandra Miller<br />

Advertising<br />

Neal.F.Miller@gmail.com<br />

<strong>NIRMA</strong> Headquarters<br />

Sarah Perkins<br />

<strong>NIRMA</strong> Administrator<br />

245 Sunnyridge Ave., #41<br />

Fairfield, CT 06824<br />

nirma@nirma.org<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 3

Georgia Power Orders First Fuel<br />

Load for Vogtle Unit 3<br />

G<br />

eorgia Power has ordered<br />

the first nuclear fuel load<br />

for Vogtle Unit 3, the first<br />

nuclear fuel order to be<br />

placed in more than 30 years for a<br />

newly-designed reactor in the U.S.<br />

The fuel order marks another<br />

significant milestone at the Vogtle<br />

nuclear expansion near Waynesboro,<br />

Georgia.<br />

Consisting of 157 fuel assemblies<br />

with each measuring 14 feet tall, the<br />

fuel will eventually be loaded into<br />

the Unit 3 reactor vessel to support<br />

startup once the reactor begins<br />

operating. After this initial fueling,<br />

approximately one third of the total<br />

fuel assemblies will be replaced<br />

during each refueling outage after<br />

the units begin operating, similar to<br />

the process used at existing Vogtle<br />

units 1 and 2.<br />

The fuel order for Vogtle Unit 3<br />

comes just months after the<br />

placement of the containment vessel<br />

top, which was witnessed by U.S.<br />

Energy Secretary Rick Perry,<br />

Georgia Governor Brian Kemp,<br />

Plant Vogtle Unit 4 (Image: Georgia Power Company)<br />

U.S. Agriculture Secretary Sonny<br />

Perdue, North America's Building<br />

Trades Unions President Sean<br />

McGarvey, members of Congress<br />

and all five members of the Georgia<br />

Public Service Commission,<br />

signifying that all modules and large<br />

components have been placed inside<br />

the unit.<br />

In addition, the placement of<br />

three low-pressure turbine rotors<br />

and the generator rotor inside the<br />

Unit 3 turbine building have also<br />

been completed. The turbine rotors,<br />

weighing approximately 200 tons<br />

each and rotating at 1,800<br />

revolutions per minute, will pass<br />

steam through the turbine blades to<br />

power the generator and supply<br />

electricity to the grid. The highpressure<br />

turbine rotor will be<br />

installed in the coming weeks.<br />

Plant Vogtle Unit 3 Containment Vessel (Image: Georgia Power Company)<br />

4 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

Plant Vogtle Unit 3 and 4 (Image: Georgia Power Company)<br />

The generator rotor is the moving<br />

component of the electromagnetic<br />

system of the electric generator. As<br />

the turbines rotate, they turn the<br />

generator rotor. The generator rotor<br />

is surrounded by the generator stator<br />

that work together creating an<br />

electromagnetic field to generate<br />

electricity.<br />

Significant progress continues to<br />

be made at the construction site as<br />

the project workforce remains at an<br />

all-time high with approximately<br />

8,000 workers on site. With more<br />

than 800 permanent jobs available<br />

once the units begin operating,<br />

Vogtle 3 & 4 is currently the largest<br />

jobs-producing construction<br />

project in the state of Georgia.<br />

Looking inside the Plant Vogtle Unit 4 cooling tower (Image: Georgia Power Company)<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 5

By Arijana Dizdarevic<br />

Sales & Marketing Coordinator, STimaging / nextScan<br />

H<br />

ow much time does it take<br />

to look up just one record<br />

from a roll of microfilm?<br />

All you need to do is<br />

retrieve ONE piece of information<br />

from it. Simple! How long could that<br />

take?<br />

In our day-to-day digital world,<br />

we have grown accustom to instantly<br />

receiving information, but anyone<br />

who’s worked with microfilm knows<br />

that getting information from that<br />

medium could result in a lengthy<br />

task. You just fell into the classic<br />

“trap” of manual retrieval – one of<br />

the biggest hidden time sinks of<br />

record requests from analog film.<br />

The trouble with pulling records<br />

from microfilm is that you are not<br />

done once you find the microfilm<br />

roll. You have only just begun. Any<br />

roll of microfilm might contain up to<br />

1,500 documents, and it’s up to you<br />

to find the requested record.<br />

How long will that take?<br />

• If you can identify a<br />

document from a quick glance<br />

at the title, one second per<br />

frame would mean it takes 25<br />

minutes to get all the way<br />

through a roll of 1,500<br />

documents.<br />

• If you have to take a more indepth<br />

look, say 10 seconds,<br />

then that could equal more<br />

than four hours per roll!<br />

• Sometimes you’ll be lucky and<br />

the document you want will<br />

be right at the start, but<br />

sometimes it’ll be at the end.<br />

Taking the average, you are<br />

looking through 750<br />

documents.<br />

• That means that a typical<br />

“quick” records search of a<br />

full roll should take about 12<br />

minutes, while an in-depth<br />

search can take hours.<br />

The reason, and of course you know,<br />

because you have to read what is on<br />

each frame of film. On a modern PC<br />

running an MS Word or PDF file,<br />

simply entering Ctrl-F allows for a<br />

search function and jumping<br />

through a few highlighted keywords.<br />

With a manual process like<br />

microfilm, you are the Ctrl-F key,<br />

because your machine can’t do it for<br />

you.<br />

Continued on next page.<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 7

STimaging<br />

next can<br />

S<br />

Of course, certain things can help you cut down<br />

the manual search time, such as a table of contents, or<br />

if you have a general idea of where in the film to look.<br />

But luck or experience is a requirement there, and on<br />

average, you’re still probably going to spend at least 5<br />

or 10 minutes on a records lookup, even if you’re<br />

good and lucky.<br />

It is time to stop<br />

manually retrieving<br />

microfilm records. Step<br />

into the digital age by<br />

converting those<br />

records to digital<br />

microfilm ribbons and<br />

find the documents<br />

practically instantly.<br />

Let the computer do<br />

what it is good at and<br />

be the Ctrl-F command.<br />

Why Digitizing Your Microfilm<br />

Collection Saves Time – And Pays<br />

for Itself in the Long Run<br />

It may look like we spent the past several<br />

paragraphs discussing how inefficient it is to manually<br />

look up records on microfilm, but what we really want<br />

to show you is how much time it saves to do the<br />

process digitally.<br />

You can conduct a search on microfilm rolls just<br />

like you can with a PDF – you just need to convert the<br />

microfilm into a digital microfilm ribbon first. Then run<br />

a simple optical character recognition program to make<br />

it searchable. Besides the obvious practical benefits, like<br />

preservation, backing up the records, and protecting<br />

your collection from “Vinegar Syndrome” rot, you’ll be<br />

able to save a lot of time by getting an assist from your<br />

computer on every search you do.<br />

Digitizing an entire roll of microfilm to a digital file<br />

format can take as little as one minute on today’s fastest<br />

high-speed conversion unit. While scanning at a high<br />

rate is beneficial to your conversion project,<br />

guaranteeing that every file was digitized is critical to<br />

record retention requirements. Combined with software<br />

designed for batch audit processing, the daunting task of<br />

combing through thousands of files is simplified with a<br />

ribbon auditor. Users can see an entire scan and quickly<br />

check for complete capture, in addition to applying<br />

universal image enhancements to the ribbon or a<br />

selected group of frames. The key to completing your<br />

conversion project in one piece and on time is not only<br />

fast scanning but also fast auditing capabilities.<br />

High-speed microfilm conversion scanners will<br />

steer your department towards maximum operational<br />

efficiency by streamlining the record retrieval process.<br />

By instituting an on-demand process your staff can<br />

capture and convert entire rolls of microfilm as records<br />

are requested without making drastic changes to your<br />

existing business process. Any time there is a records<br />

request, simply capture the whole roll instead, find what<br />

you’re looking for using a fast search, and keep the<br />

digital copy forever – all in about the same amount of<br />

time it would have taken you to find the information<br />

manually.<br />

It is time to stop manually retrieving microfilm<br />

records. Step into the digital age by converting those<br />

records to digital microfilm ribbons and find the<br />

documents practically instantly. Let the computer do<br />

what it is good at and be the Ctrl-F command.<br />

STimaging<br />

S<br />

next can<br />

Click here to<br />

Contact us!<br />

8 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

From the President<br />

Michelle M. Smith<br />

T<br />

his past month the <strong>NIRMA</strong> Board of<br />

Directors met for our Winter Board meeting.<br />

The Board collectively reviewed our Strategic<br />

Plan and goals. We took an in-depth look at<br />

how we will achieve our goals for <strong>2020</strong>. The <strong>NIRMA</strong><br />

Strategic Plan states <strong>NIRMA</strong> is the industry leader in<br />

information and records management, uniquely<br />

qualified to provide:<br />

• guidance to our members in the areas of<br />

quality records programs,<br />

• regulatory compliance activities,<br />

• electronic records initiatives,<br />

• document management technologies, and<br />

• knowledge management issues.<br />

To comply with our Strategic Plan and goals<br />

<strong>NIRMA</strong> continues to seek visionaries to share ideas<br />

and to create a platform for our audience to discuss<br />

how to address the industry’s biggest challenges and<br />

create opportunities through using innovative tools.<br />

<strong>NIRMA</strong> has been working with industry peers to<br />

identify speakers for the upcoming conference. We<br />

have an array of presenters with topics that will be<br />

prevalent to our industry.<br />

Just a few of the top speakers already<br />

confirmed for <strong>2020</strong> include:<br />

• David Nelson, NRC Chief Information<br />

Officer and Chief Data Officer, will provide<br />

an overview of the NRC initiatives that will<br />

drive changes for our industry on August 2.<br />

• Colleen R. McClanahan, Directorate,<br />

Management & Program Analyst, FAC-COR<br />

with the Federal Bureau of Investigation on<br />

August 2.<br />

• Laura Williams, with the American Nuclear<br />

Insurers (ANI) has an extensive background<br />

in Health Physics and Decommissioning, will<br />

be the Keynote Speaker on August 3.<br />

• Karen Fili, current President & CEO of<br />

URENCO USA. Previously Site VP at<br />

Southern Company for Vogtle 3 & 4, and Site<br />

VP at Monticello Nuclear plant, will be the<br />

Keynote Speaker on August 4.<br />

For additional information on two Keynote<br />

Speakers, see pages 12 and 13.<br />

If you would like to present a topic or get involved<br />

in <strong>NIRMA</strong>, please contact us at nirma@nirma.org.<br />

Not a Member of <strong>NIRMA</strong>?<br />

Click here to join today!<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 9

I<br />

A Retrospective on Information<br />

Management in Nuclear Power<br />

By Eugene Y. Yang, KISMET Consulting, Inc.<br />

t was not necessarily always<br />

about document control and<br />

records management. I did<br />

process improvement consulting from<br />

the 1990’s and into 2000’s when<br />

“globalization” really emerged and<br />

competition was for real. This<br />

resulted in the “right-sizing” of<br />

companies; deregulation came to the<br />

electric utility sector, forcing the<br />

nuclear power industry to look at<br />

better efficiencies. This issue’s article<br />

reflects my experience in process<br />

improvement versus technology<br />

change.<br />

Growing up, I was a big fan of<br />

science fiction. I loved anthologies;<br />

you could<br />

read a<br />

variety of<br />

great short<br />

stories, filled<br />

with science<br />

“gee whiz”.<br />

One story<br />

that stuck<br />

with me was<br />

“The<br />

Specter<br />

General” by<br />

Theodore<br />

Cogswell. A maintenance battalion<br />

of the Imperial Space Marines<br />

establishes a<br />

base on an<br />

uninhabited<br />

planet, but it’s<br />

forgotten as the<br />

empire falls<br />

into civil war. For the next 500<br />

years, the soldiers doggedly stick to<br />

their mission in training for starships<br />

that never come. They lapse into a<br />

primitive farming and hunting<br />

existence, exhibiting characteristics<br />

of the American Indian culture.<br />

“Braves” are garbed in buckskin,<br />

wearing feathers that identify their<br />

company or platoon, and on their<br />

arms are painted rank insignia. One<br />

day, starships do show up, but they<br />

are sorely in need of maintenance.<br />

One particular brave immediately<br />

identifies one of the problems and<br />

fixes it. Astonished, the starship<br />

captain asks how did the brave know<br />

how to repair the problem, the brave<br />

shrugged and said, “That’s how I’ve<br />

always done it.”<br />

Starting in the late 1970s and into<br />

the 1990’s, the resurgent Japanese<br />

industrial base produced<br />

competitively priced, high-quality<br />

goods, staggering the economies of<br />

North America and Western Europe.<br />

For example, the United Kingdom,<br />

for the first time since the Industrial<br />

Revolution, became a net importer<br />

of finished goods. The big secret?<br />

The Japanese studied, implemented,<br />

and refined the quality management<br />

principles espoused by W. Edward<br />

Demig: Plan-Do-Study-Act (PDSA).<br />

“Process Improvement”, “Process<br />

Re-engineering”, and other like<br />

terms became all the rage.<br />

A good portion of the consulting<br />

that I did in those days was directed<br />

at achieving greater production in<br />

the capture, review, indexing,<br />

storage, and disposition of<br />

documents and records piling up at<br />

near mythic volumes. This work<br />

addressed not only fundamental<br />

recordkeeping processes, but also<br />

major plant processes, such as design<br />

change/modification, supply chain,<br />

maintenance management, and<br />

configuration management. I got to<br />

use cool (well, at the time!) tools<br />

such as MetaVision or IEW’s<br />

Knowledgeware that helped in<br />

modeling processes.<br />

The debate back then (and<br />

continues today!) is: which “answer”<br />

takes the lead - is it an improved<br />

process or is it better technology? I<br />

am still amused at the “armed<br />

10 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

camps” – the “process” or business people were all<br />

about the latest and greatest computer technology that<br />

would take care of their problems, and the information<br />

technologists would be about getting the “fill-in-theblank<br />

users” to come up with a cogent process<br />

description so they could fit in the technology.<br />

When I would facilitate a process review, there would<br />

be times when I’d scratch my head on a particular series<br />

of steps, and ask “why do you do this?” I’d get back,<br />

“That’s how we’ve always done it.” I would then think,<br />

you know, that’s a bad process; if they implement the<br />

system according to this process, they’re only making a<br />

bad process go faster! On the other hand, the nature-of<br />

-the-beast with technology is that there is an inherent<br />

“management system” in the software, processes that<br />

may not fit a company’s current culture or processes.<br />

So, do you adopt the process to meet the system, or do<br />

you adopt the system to meet the process?<br />

I’ve seen it both ways, with extraordinary hoopjumping<br />

and accompanying cultural angst. On one<br />

hand, so much change was done to a software<br />

application to meet a company’s process that it was<br />

Back then, the buzzword<br />

that got change going<br />

was “total quality<br />

management”; today,<br />

it’s Lean-Six Sigma.<br />

Tomorrow? No doubt<br />

there will be another<br />

methodology to get<br />

excited about, but the<br />

clash will be the same: is<br />

it process improvement<br />

or technology change?<br />

nearly unrecognizable if you saw that system used in<br />

another company. On the other hand, I’ve seen “edicts<br />

from on high” that the software must be used “as-is”,<br />

so the company needs to change its ways of doing<br />

business to meet it. Don’t get me wrong; there are valid<br />

reasons for either way, with justified cost-benefits, it’s<br />

just an interesting dichotomy I’ve observed – or been a<br />

part of!<br />

The best implementations, especially at the fleet-wide<br />

scale, is where a compromise is achieved between<br />

process improvement and technology change. There are<br />

some processes that must stay in place in order to meet<br />

regulatory needs (“if the process is bad, go tell the<br />

guv’mint!”); on the other hand, if a software company<br />

has a track record of effective success, a client should<br />

“listen” as to why the automated process is in place and<br />

strive to implement it.<br />

Back then, the buzzword that got change going was<br />

“total quality management”; today, it’s Lean-Six Sigma.<br />

Tomorrow? No doubt there will be another<br />

methodology to get excited about, but the clash will be<br />

the same: is it process improvement or technology<br />

change?<br />

Eugene has been a member of <strong>NIRMA</strong> for<br />

over 33 years. At the time he joined,<br />

<strong>NIRMA</strong> had only been in existence for 11<br />

years. He would love to hear about stories<br />

and anecdotes from others, so please email<br />

him at:<br />

eugene.yang@kismetconsulting.com.<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 11

<strong>NIRMA</strong> <strong>2020</strong> Conference<br />

Keynote<br />

speaker<br />

David Nelson currently serves as<br />

the Chief Information Officer (CIO)<br />

and Chief Data Officer (CDO) of<br />

the Nuclear Regulatory Commission<br />

(NRC). Mr. Nelson was selected for<br />

this role in 2016 to oversee the<br />

NRC’s information technology/<br />

information management (IT/IM)<br />

portfolio, including those IT systems<br />

supporting nuclear reactor safety and<br />

nuclear materials and waste safety.<br />

In addition to the IT/IM<br />

portfolio, Mr. Nelson is responsible<br />

for the NRC’s information resource<br />

management, enterprise architecture<br />

program, cybersecurity program,<br />

information and records<br />

management program, information<br />

collection program, and the agency’s<br />

implementation of the Freedom of<br />

Information Act and the Federal<br />

Privacy Act of 1974.<br />

Mr. Nelson previously held<br />

several executive roles at the Centers<br />

for Medicare and Medicaid Services<br />

(CMS), including CIO and Director,<br />

Office of Enterprise Information;<br />

Director, Office of Information<br />

Services; Director, Office of<br />

Enterprise Management; and<br />

Director, Data Analytics and Control<br />

Group for the Center for Program<br />

Integrity. Mr. Nelson’s Office<br />

managed the CMS’s $2.6 billion IT<br />

portfolio, including the complex<br />

ecosystem of applications and<br />

trusted data exchanges supporting<br />

Healthcare.gov, the Medicare claims<br />

processing system, and the Medicaid<br />

support and quality reporting<br />

systems. Mr. Nelson joined CMS in<br />

2004 as the Director, Division of<br />

Call Center Systems, Office of<br />

External Affairs and Beneficiary<br />

Services, and was charged with<br />

improving access to information for<br />

40 million Medicare beneficiaries.<br />

Before joining CMS, Mr. Nelson<br />

served in a variety of challenging<br />

private sector leadership roles,<br />

including co-founder of two<br />

broadband development companies<br />

that provided access to underserved<br />

markets in the United States.<br />

Mr. Nelson also served in<br />

executive operations roles both in<br />

the United States and abroad for<br />

several leading IT development and<br />

telecommunications companies, and<br />

as Vice President of Operations for a<br />

telecommunications firm where he<br />

managed the commissioning of<br />

several hundred satellite earth<br />

stations in 50 countries across<br />

Europe, Latin America, and the<br />

United States.<br />

Save the<br />

date!<br />

The 44 th Annual Nuclear<br />

Information Management<br />

Conference will be held on<br />

August 2-4, <strong>2020</strong>.<br />

12 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

<strong>NIRMA</strong> <strong>2020</strong> Conference<br />

Keynote<br />

speaker<br />

Colleen McClanahan is a<br />

Management & Program Analyst<br />

with the Federal Bureau of<br />

Investigation (FBI). Ms.<br />

McClanahan began her FBI career in<br />

2011 where she managed multiple<br />

information technology contracts in<br />

the FBI’s Information Technology<br />

Branch. Ms. McClanahan<br />

transferred to the Weapons of Mass<br />

Destruction Directorate (WMDD) is<br />

2013 where she managed the<br />

Directorate’s Contract<br />

Administration Program and<br />

implemented executive management<br />

strategic objectives regarding<br />

personnel assets. In 2014, she<br />

transferred to her current position,<br />

within WMDD, to the Nuclear and<br />

Radiological Countermeasures Unit<br />

(NRCU). Ms. McClanahan has<br />

provided program management on<br />

several international and domestic<br />

nuclear and radiological programs<br />

where she provides subject matter<br />

expertise on implementing<br />

countermeasures and tripwires to<br />

prevent, detect and respond to<br />

radiological and nuclear terrorism<br />

incidents.<br />

In addition to her day-to-day<br />

responsibilities in NRCU, Ms.<br />

McClanahan is a member of the<br />

FBI’s Victim Services Response<br />

Team where she supports the FBI’s<br />

response to mass casualty incidents.<br />

Ms. McClanahan received her<br />

Bachelor’s Degree in<br />

Communication Studies from<br />

Towson University. Prior to joining<br />

the FBI, Ms. McClanahan was the<br />

Director of Administration and<br />

Meetings Manager for Bostrom<br />

Corporation, an association<br />

management company.<br />

Ms. McClanahan will present<br />

“How the Federal Bureau of<br />

Investigation (FBI) Counters the<br />

Radiological Threat”.<br />

Description: The mission of the<br />

FBI is to protect the American<br />

people and uphold the Constitution<br />

of the United States. The FBI<br />

created the Weapons of Mass<br />

Destruction Directorate (WMDD)<br />

to build a cohesive and coordinated<br />

approach to incidents involving<br />

chemical, biological, radiological,<br />

nuclear, or explosive (CBRNe)<br />

material—with an overriding focus<br />

on prevention. Through a nuclear<br />

and radiological tripwire initiative,<br />

the FBI provides awareness briefing<br />

that discuss potential threats and<br />

vulnerabilities regarding the use of,<br />

research of, or manufacturing of<br />

radiological sources. The purpose of<br />

this presentation is to discuss:<br />

• An overview of the FBI,<br />

• the role of the WMD<br />

Coordinator,<br />

• types of threats applicable to<br />

<strong>NIRMA</strong> members,<br />

• suspicious behaviors, and<br />

• real world case studies.<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 13

<strong>NIRMA</strong> Transforming the<br />

<strong>2020</strong> Conference<br />

Janice Hoerber, Vice President<br />

I<br />

<strong>2020</strong>).<br />

t is an exciting time as we<br />

plan for the 44 th Nuclear<br />

Information Management<br />

Conference (August 2-4,<br />

<strong>NIRMA</strong> is embracing change and<br />

unveiling a new look for the <strong>2020</strong><br />

conference in the exclusive Palms<br />

Executive Conference Center at the JW<br />

Marriott Las Vegas Resort and Spa.<br />

For over a decade, the conference<br />

has been located in the Marquis<br />

Conference area. The <strong>NIRMA</strong><br />

Board is delighted with the new<br />

conference space in the Palms<br />

Tower and believe it will be a<br />

welcomed change for attendees and<br />

vendor exhibitors.<br />

The <strong>2020</strong> <strong>NIRMA</strong> Conference<br />

schedule will be changed up to<br />

revitalize the tracks and session<br />

topics to meet the needs of a<br />

broader audience. Each day will<br />

include a special Keynote speaker to<br />

share industry perspectives. An<br />

emphasis will also be on a<br />

Fundamentals track Sunday for the<br />

beginner as well as those looking for<br />

a refresher. Your feedback from last<br />

year's conference has been helpful in<br />

making adjustments for this August!<br />

We look forward to a terrific<br />

lineup of speakers and topics in<br />

August! The Call for Papers is<br />

posted on the <strong>NIRMA</strong> website (click<br />

here) with a variety of relevant topics<br />

to consider. Submit your 100-150<br />

word abstract of your presentation<br />

in March to Janice Hoerber,<br />

<strong>NIRMA</strong> Vice President at<br />

jhoerber@ameren.com.<br />

This year's<br />

<strong>NIRMA</strong><br />

conference<br />

theme is focused<br />

on the Nuclear<br />

Transformation<br />

and Embracing<br />

Change in your<br />

workplace.<br />

The <strong>NIRMA</strong> conference offers a<br />

forum for excellent networking.<br />

The conference schedule will be<br />

packed with learning opportunities<br />

as well as knowledge sharing among<br />

peers and the regulators.<br />

Highlight of the <strong>2020</strong><br />

Conference events:<br />

• Educational Opportunities<br />

for signup (coming soon)<br />

Saturday, August 1<br />

• Opening Day Keynote, plus<br />

ICRM Prep &<br />

Fundamentals track Sunday,<br />

August 2<br />

• Welcome Reception (food &<br />

beverages) early evening,<br />

Sunday, August 2<br />

• Vendor Exhibits & Raffles<br />

Monday, August 3 with<br />

dedicated Solution Spotlight<br />

talks<br />

• Keynotes, Technical<br />

Sessions and Panel<br />

Discussions Monday &<br />

Tuesday, August 3-4<br />

• <strong>NIRMA</strong> Business Unit<br />

meetings Wednesday, August<br />

5 & tentatively Thursday,<br />

August 6<br />

The Vendor Exhibitor<br />

Extravaganza will have a great new<br />

look Monday, August 3 in the<br />

Cascades ballroom!<br />

Continue checking the <strong>NIRMA</strong><br />

website at www.nirma.org for all the<br />

details and to register for the<br />

conference. We look forward to<br />

seeing you there!<br />

14 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

Sheila Pearcy, CRA<br />

W<br />

ell it has been a good year<br />

and here we are off to a<br />

good start for <strong>2020</strong>. The<br />

<strong>NIRMA</strong> Board of Directors<br />

(BOD) met in Summerlin for the Biannual<br />

Board Meetings in February.<br />

Much was accomplished. The Board<br />

discussed, reviewed and established:<br />

• <strong>NIRMA</strong> <strong>2020</strong> BOD Goals<br />

• Status of <strong>NIRMA</strong> Organization<br />

• Treasurer’s Report and <strong>2020</strong><br />

Budget<br />

• 5-Year Strategic Plan<br />

• SWOT (Strengths, Weaknesses,<br />

Opportunities, Threats)<br />

SUMMARY of <strong>NIRMA</strong> 2019<br />

ACCOMPLISHMENTS:<br />

• Successful 43rd Annual <strong>NIRMA</strong><br />

Conference.<br />

• <strong>NIRMA</strong> Board managed<br />

expenses closely in 2019 to net a<br />

positive finish for the year.<br />

• 3 Outstanding <strong>NIRMA</strong><br />

Magazines were produced and<br />

published.<br />

• Eugene Yang represented<br />

<strong>NIRMA</strong> in the United Arab<br />

Emirates by providing training<br />

and instruction to ENEC.<br />

• Selected the <strong>2020</strong>, Nominating<br />

Committee – Denise Pickett and<br />

Ed <strong>Spring</strong>er.<br />

• <strong>NIRMA</strong>’s social media presence<br />

has tripled for Facebook and<br />

Twitter.<br />

• Board approved WP-06, <strong>NIRMA</strong><br />

Decommissioning White Paper.<br />

• Board agreed to $50.00 <strong>NIRMA</strong><br />

membership cost for Nuclear<br />

Specialist (NS) Retired Members<br />

• Revised AP02, Annual Election<br />

and Board of Directors<br />

Reorganization Process.<br />

• Approved TG22, Management<br />

of Electronic Vendor Technical<br />

Documents and PP06,<br />

Alternative Approaches in the<br />

Implementation of the NRC<br />

Regulatory Issue Summary.<br />

• <strong>NIRMA</strong> was requested by NEI<br />

to present at the NEI<br />

Decommissioning Task Force.<br />

Eugene Yang presented on<br />

behalf of <strong>NIRMA</strong> - WP06 the<br />

<strong>NIRMA</strong> White Paper on<br />

Decommissioning.<br />

• Published ICRM Nuclear<br />

Specialist (NS) Brochure.<br />

• Two members Kathi Cole and<br />

Denise Pickett represented<br />

<strong>NIRMA</strong> at the annual 2019<br />

ARMA Conference to support<br />

Industry outreach.<br />

• Bruce Walters and Gil Bruckner<br />

were honored at the <strong>NIRMA</strong><br />

Annual Business Meeting for<br />

achieving the prestigious Nuclear<br />

Specialist (NS) certification.<br />

• M&M provided ongoing support<br />

of LinkedIn, Facebook, and<br />

Twitter as well as the <strong>NIRMA</strong><br />

Monthly Emails to the<br />

membership with the help of<br />

Devereaux Consulting. Posting<br />

organizational information,<br />

industry news and special<br />

notifications as requested by the<br />

Board. M&M BU has developed<br />

a draft Mentoring Program.<br />

• PDBU offered the Preconference<br />

training “Do You See<br />

the Flow?” on business process<br />

mapping and process<br />

improvements.<br />

• RIMBU continues to review<br />

Technical Guidelines for<br />

technical accuracy and validity,<br />

per the biannual review schedule.<br />

AUGUST 2019 BOARD<br />

ELECTION/<br />

REORGANIZATION<br />

RESULTS:<br />

President: Michelle Smith, STP<br />

Vice President: Janice Hoerber,<br />

Ameren Services<br />

Secretary: Sheila Pearcy, CRA,<br />

Regulatory Environmental Services<br />

(RES)<br />

Treasurer: Anita Beren, GE<br />

Healthcare<br />

Director of Infrastructure: Bruce<br />

Walters, CRM/NS, AECOM<br />

Director of Technical Programs:<br />

Lona Smith, STP<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 15

Professional<br />

Development<br />

Business Unit (PDBU)<br />

News<br />

Tammy Cutts, PDBU Director<br />

P<br />

rofessional development has a lot to offer<br />

individuals. These offerings can be personal;<br />

you can become better at your job, develop<br />

confidence in practicing your profession, prepare for<br />

future positions, or stay engaged in your current work.<br />

It's a requirement for individual's holding professional<br />

certifications such as CRA, CRM, IGP, CIP, etc. Your<br />

employers, current or future, reap benefits from your<br />

development as well.<br />

Professional development can be a lot of different<br />

experiences, and <strong>NIRMA</strong> is pleased to provide some of<br />

those to its members.<br />

Looking for opportunities?<br />

Consider the following:<br />

• Attend the <strong>NIRMA</strong> conference for benchmarking<br />

and sessions.<br />

• Enroll in the pre-conference workshop.<br />

• Those new to records management can attend<br />

Sunday sessions on the basics.<br />

• Those further along in their careers and looking to<br />

add a professional certification can attend the ICRM<br />

exam prep workshop on Sunday afternoon to learn<br />

about taking the CRA parts. And for existing<br />

CRAs/CRMs, there will be a NS and Fed exam<br />

review on Monday or Tuesday.<br />

• Already a CRA or CRM? Try the specialist<br />

designation (NS or Federal) prep on Monday.<br />

• Individuals with professional certifications can earn<br />

maintenance points by leading sessions.<br />

• Those with something to share can learn from the<br />

experience of developing and presenting a session<br />

while contributing to the development of attendees<br />

(click here to see the Call for Papers for the<br />

conference).<br />

I'm excited about the upcoming conference with its<br />

various offerings and I look forward to seeing you there!<br />

<strong>NIRMA</strong>’s Financial Holdings<br />

As of: February 20, <strong>2020</strong><br />

Anita S. Beren<br />

<strong>NIRMA</strong> Treasurer<br />

Checking Account $ 48,840.89<br />

Investment Account $ 132,046.10<br />

Debit Account $ 149.37<br />

16 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

MEMBERSHIP & MARKETING (M&M)<br />

Business Unit News<br />

Kathi Cole, M&MBU Director<br />

e are less than 6 months away from the <strong>2020</strong><br />

W<br />

<strong>NIRMA</strong> Conference. Time to start really<br />

thinking about attending the conference. There<br />

are great ways to enjoy and participate in the<br />

learning and fun.<br />

We have lined up some amazing Keynote<br />

speakers for this Conference. In the coming months, we<br />

will be sharing more details about topics, but right now<br />

we have speakers from the NRC, FBI, American<br />

Nuclear Insurers (ANI), and a former Site VP from<br />

Vogtle and Monticello nuclear plants. You and your<br />

work colleagues are going to want to hear these<br />

presentations … which leads us to the next topic.<br />

BRING-a-BUDDY” Campaign!<br />

We will again be promoting the “BRING-a-<br />

BUDDY” campaign in <strong>2020</strong>. When you register yourself<br />

and a “buddy” (a new attendee) to come to the <strong>2020</strong><br />

<strong>NIRMA</strong> conference, your names will be placed in a<br />

special drawing. Prizes are always fun! Remember to<br />

register by July 1st and receive the Early Bird Discount.<br />

The new attendee can be anyone from your<br />

J<br />

ust a reminder that the election for the <strong>NIRMA</strong><br />

Board of Directors will occur in July and we<br />

need your help in filling the two Board positions<br />

that are open for election. Please consider<br />

nominating yourself or other individuals who you<br />

consider qualified to fill these leadership positions for<br />

the Association.<br />

organization, such as IT, your<br />

boss, procedure writers, auditors,<br />

engineers, etc.<br />

<strong>NIRMA</strong> is offering a<br />

group discount when you register for the Conference<br />

early. Purchase 3 registrations from the same company,<br />

and all subsequent registrations are $600. These<br />

subsequent employees need not be part of the Records<br />

Management organization. They can be employees from<br />

any of the organizations within the same company.<br />

<strong>NIRMA</strong> is also offering a discounted price for your boss<br />

for $500 with your paid registration.<br />

Mentoring Program<br />

A draft Mentoring Program has been presented<br />

to the Board for consideration. Once approved and<br />

implemented, it will enable members to seek guidance<br />

from our more experienced members on a number of<br />

topics. We will be needing individuals to step up to<br />

become those mentors. Stay tuned. For additional<br />

information or questions, please contact Kathi Cole at<br />

kjccole1@yahoo.com or Denise Pickett at<br />

denisearma@gmail.com.<br />

UPCOMING ELECTION NEWS FROM THE<br />

NOMINATING COMMITTEE<br />

Denise L. Pickett, CRM/NS/FED, IGP<br />

Nominations for <strong>NIRMA</strong><br />

Board of Directors<br />

professional qualification, and desire and ability to serve<br />

on the Board. The term is three years.<br />

Please send your nominations to the Nominating<br />

Committee members, Denise Pickett at<br />

denise.pickett.crm@gmail.com or Ed <strong>Spring</strong>er at<br />

edgar.springer@pseg.com by April 25, <strong>2020</strong>.<br />

Factors to include in your consideration are length<br />

of time as a <strong>NIRMA</strong> member, committee activities,<br />

leadership positions held, service to <strong>NIRMA</strong>,<br />

Denise or Ed will provide proposed candidates with<br />

documents and guidance per AP02, Annual Election<br />

and Board of Directors Reorganization Process.<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 17

NuScale Submits SMR Design to<br />

Canadian Nuclear Safety Commission<br />

A NuScale power plant could house up to 12 individual power modules<br />

(Image: NuScale)<br />

NuScale has made its first submittal<br />

to the Canadian Nuclear Safety<br />

Commission (CNSC) for pre-licensing<br />

vendor design review (VDR) of its SMR<br />

design.<br />

This submission reflects the<br />

substantive work that NuScale<br />

continues to accomplish in the<br />

regulatory field as the company is<br />

simultaneously bringing the U.S.’s first<br />

NuScale power plant into production<br />

and operation by 2026. “Interest in<br />

building NuScale plants in Canada<br />

continues to grow. This pre-licensing<br />

process allows our design to be<br />

reviewed by another highly respected<br />

regulator, the Canadian Nuclear Safety<br />

Commission, and we look forward to<br />

their thorough evaluation of our<br />

innovative safety features,” said NuScale<br />

Chairman and Chief Executive Officer<br />

John Hopkins.<br />

“We are thrilled to continue our path<br />

forward to introduce our scalable,<br />

economic, carbon-free, and safe SMR<br />

technology to Canadian customers.”<br />

Building on the US Nuclear<br />

Regulatory Commission’s (NRC) design<br />

certification application (DCA) process,<br />

the submission to CNSC will allow a<br />

potential customer to maximize<br />

increased efficiencies for technical<br />

reviews when later seeking to submit a<br />

construction license application,<br />

according to NuScale.<br />

NuScale’s design is the world’s first<br />

SMR to undergo design certification<br />

review by the NRC, completing Phase 4<br />

of its DCA in December.<br />

NuScale has signed an agreement<br />

with Bruce Power to develop a business<br />

case to support the company’s efforts to<br />

bring its SMR technology to Canada.<br />

Ontario Power Generation participates<br />

on the NuScale Advisory Board and<br />

provides advice.<br />

Article reprinted with permission of<br />

Nuclear Energy <strong>Inside</strong>r. Read full<br />

article here.<br />

New Study Finds<br />

Nuclear Energy<br />

Significant for<br />

Washington’s Clean<br />

Energy Goals<br />

Washington, D.C.—Energy Northwest<br />

unveiled a new study that lays out a path to<br />

reliably achieve 100% carbon-free energy by<br />

2045 through clean resources like wind, solar<br />

and nuclear energy. The study from Energy<br />

+ Environmental Economics identifies<br />

pathways to reduce carbon emissions that<br />

includes preserving current nuclear plants<br />

through second license renewals and the<br />

deployment of innovative SMR. These<br />

findings build on a consensus that nuclear<br />

energy, and even more of it, will be needed to<br />

meet climate goals because it provides reliable<br />

carbon-free electricity, 24/7.<br />

The following statement can be<br />

attributed to Maria Korsnick,<br />

president and chief executive officer<br />

of the Nuclear Energy Institute:<br />

“Today, Energy Northwest released<br />

a study that clearly demonstrates the<br />

important role of nuclear energy in a<br />

carbon-free future. Key to the success<br />

in reaching Washington state’s clean<br />

energy transformation is the license<br />

renewal of the Columbia Generating<br />

Station nuclear power plant and the<br />

availability of firm, carbon-free<br />

generation, like that offered by small<br />

modular reactors.<br />

“SMR will provide always-on,<br />

reliable energy that can seamlessly<br />

complement wind and solar. The cost<br />

feasibility study shows that they can be<br />

a critical component of any plan to<br />

reach net-zero carbon emissions in a<br />

cost-effective way.”<br />

Article reprinted with permission<br />

of NEI. Read full article here.<br />

18 <strong>Spring</strong> <strong>2020</strong> <strong>NIRMA</strong>.org <strong>Inside</strong> <strong>NIRMA</strong>

The Versatile Test Reactor Can Help Unlock the<br />

Future of Carbon-Free Energy<br />

The <strong>2020</strong>s will be the decade of innovations in<br />

nuclear energy. The technologies and tools that will enable<br />

advanced nuclear reactors to become a reality are being<br />

developed now.<br />

Those more energetic neutrons have many<br />

advantages. They can split a much wider variety of atoms to<br />

make energy, including many atoms that were produced in<br />

today’s reactors and would otherwise be considered waste.<br />

They can run reactors that operate at much higher<br />

temperatures than are common today, which would produce<br />

steam that can be used for many more purposes. And many<br />

of those designs would run at far lower pressures, making<br />

them easier and less expensive to build.<br />

Versatile Test Reactor<br />

The U.S. Department of Energy’s Versatile Test<br />

Reactor (VTR) is one of those cutting-edge, specialized tools.<br />

Just getting under way, the VTR is intended to mimic the<br />

conditions that would exist in a category of advanced<br />

reactors now under development: fast reactors, which<br />

include sodium-cooled fast reactors, molten salt reactors and<br />

high-temperature gas reactors.<br />

With a pressing need to reduce carbon emissions<br />

and a growing worldwide demand for electricity, it is urgent<br />

to commercialize advanced reactor technologies, many of<br />

which use molten salt, sodium or helium gas (instead of<br />

water, as current plants do).<br />

Fast reactors are quite different than the reactors<br />

currently operating in the United States. When they run, the<br />

neutrons—subatomic particles that sustain the chain<br />

reaction—are moving with vastly more energy than in<br />

today’s reactors, in some cases with 100,000 times more<br />

energy.<br />

Those more energetic neutrons have many<br />

advantages. They can split a much wider variety of atoms to<br />

make energy, including many atoms that were produced in<br />

today’s reactors and would otherwise be considered waste.<br />

They can run reactors that operate at much higher<br />

temperatures than are common today, which would produce<br />

steam that can be used for many more purposes. And many<br />

of those designs would run at far lower pressures, making<br />

them easier and less expensive to build.<br />

There is a catch, though. No one is completely sure<br />

how all of the components of these new reactors would<br />

behave after a few decades in the stew of high-energy<br />

neutrons. And engineers don’t want to wait to find out.<br />

With a simulated environment, engineers can bathe<br />

the components in neutrons at a pace three or four times<br />

faster than they would see in an actual power reactor, pull<br />

the parts out for evaluation, and if necessary, make changes<br />

and try again. This is exactly what the VTR would provide.<br />

“We want to do a quick screening of these<br />

technologies,” said Kemal Pasamehmetoglu, executive<br />

director of the VTR project.<br />

In fact, the reactor could also be used to test<br />

materials for other industries and for materials that could be<br />

useful in today’s reactors.<br />

To prosper, experts say the U.S. needs its own hightech<br />

test facility for fast neutrons.<br />

Article reprinted with permission<br />

of NEI. Read full article here.<br />

<strong>Inside</strong> <strong>NIRMA</strong> <strong>NIRMA</strong>.org <strong>Spring</strong> <strong>2020</strong> 19

<strong>Inside</strong> <strong>NIRMA</strong> Magazine is published three times<br />

annually, in March, June and October.<br />

Click here to view past issues visit.<br />

Vogtle Unit 3 Reactor Vessel<br />

Cavity, see article on Page 4.