motion-control-drives-D31-5-complete-English-2020-03-Update-2020-08

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

© Siemens <strong>2020</strong><br />

System overview<br />

■ Overview<br />

Step by step to more efficiency<br />

One of the core objectives of the European Union is a sustainable<br />

power industry. In industrial plants today, around 70 % of<br />

the power demand is from electrically driven systems. This high<br />

percentage contains huge potential for saving energy in electrical<br />

<strong>drives</strong>. For that reason, the European Union introduced<br />

minimum requirements for the energy efficiency of electric<br />

motors in the form of a statutory motor regulation as early as<br />

2011.<br />

However, measures aimed solely at the motor are not enough to<br />

achieve the mandatory energy-saving targets. The European<br />

legislation fills this gap with the standard series EN 50598 and<br />

extends the focus from individual drive components to entire<br />

drive systems, even enabling consideration of specific use<br />

cases.<br />

The European standard series EN 50598 defines the ecodesign<br />

requirements for drive systems in the low-voltage range with an<br />

electrically driven machine. It consists of definitions for energy<br />

efficiency (parts 1 and 2) and an ecobalance calculation<br />

(part 3).<br />

To take account of the different use cases, consideration of eight<br />

application-relevant operating points has been introduced as<br />

mandatory for the first time. Determination of loss values at these<br />

eight points and definition of efficiency classes are laid down by<br />

the standard in a uniform way. This enables data relevant to<br />

operation, such as application-specific load profiles, to now be<br />

taken into account more easily in the energy efficiency analysis.<br />

The standard is especially important for variable-speed <strong>drives</strong> of<br />

the following types:<br />

• for AC/AC converters without energy recovery functionality<br />

• for motors with integrated converters<br />

• for supply voltages of 100 V to 1000 V<br />

• for power ratings of 0.12 kW to 1000 kW<br />

To cover all applications of driven machines, the new standard<br />

defines operating points in full-load and partial-load operation,<br />

at which the losses of the motor and drive systems have to be<br />

determined. Based on the loss data at the operating points in<br />

partial-load operation, variable-speed <strong>drives</strong> can be explicitly<br />

considered in more detail. This makes their advantages<br />

especially clear.<br />

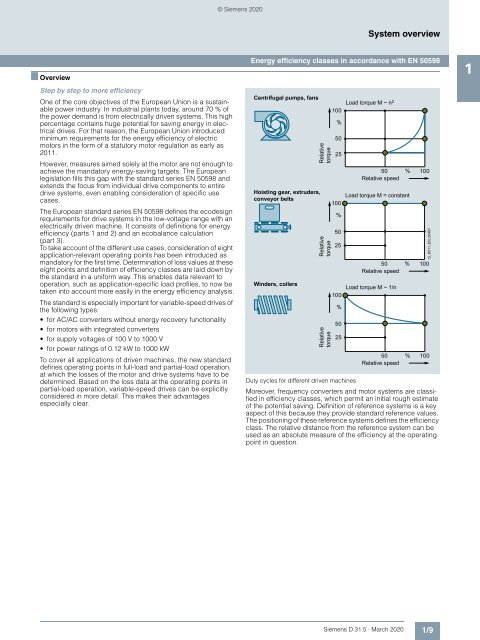

Energy efficiency classes in accordance with EN 50598<br />

Centrifugal pumps, fans<br />

Hoisting gear, extruders,<br />

conveyor belts<br />

Winders, coilers<br />

Relative<br />

torque<br />

Relative<br />

torque<br />

Relative<br />

torque<br />

100<br />

%<br />

50<br />

25<br />

100<br />

%<br />

50<br />

25<br />

100<br />

%<br />

50<br />

25<br />

Load torque M ~ n 2<br />

50<br />

Relative speed<br />

50<br />

Relative speed<br />

Duty cycles for different driven machines<br />

Moreover, frequency converters and motor systems are classified<br />

in efficiency classes, which permit an initial rough estimate<br />

of the potential saving. Definition of reference systems is a key<br />

aspect of this because they provide standard reference values.<br />

The positioning of these reference systems defines the efficiency<br />

class. The relative distance from the reference system can be<br />

used as an absolute measure of the efficiency at the operating<br />

point in question.<br />

%<br />

Load torque M = constant<br />

Load torque M ~ 1/n<br />

50<br />

Relative speed<br />

%<br />

%<br />

100<br />

G_D011_EN_00467<br />

100<br />

100<br />

1<br />

Siemens D 31.5 · March <strong>2020</strong><br />

1/9