bioplasticsMAGAZINE_1201

bioplasticsMAGAZINE_1201

bioplasticsMAGAZINE_1201

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Automotive<br />

PLA and carbon nanotubes<br />

Nanotechnology for automotive applications<br />

Conductivity (S/cm)<br />

1,4<br />

1,2<br />

1<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

0<br />

By<br />

A. Tielas, V. Ventosinos, M. de Dios<br />

Plastic Product / Process Area<br />

Engineering & Development Department<br />

Galician Automotive Technological Centre<br />

(CTAG)<br />

Porriño, Spain<br />

PLA/CNT (7%) PLA/CNT (7%)<br />

Talc (10%)<br />

PP/CNT (7%) PP/CNT (7%)<br />

Talc (10%)<br />

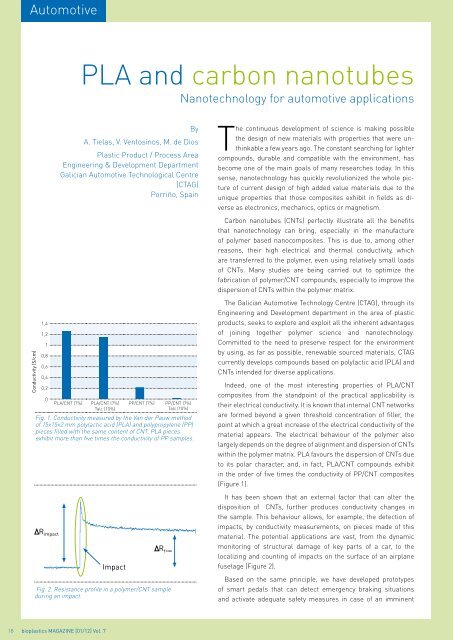

Fig. 1. Conductivity measured by the Van der Pauw method<br />

of 15x15x2 mm polylactic acid (PLA) and polypropylene (PP)<br />

pieces filled with the same content of CNT. PLA pieces<br />

exhibit more than five times the conductivity of PP samples.<br />

R impact<br />

Impact<br />

R t=∞<br />

Fig. 2. Resistance profile in a polymer/CNT sample<br />

during an impact.<br />

The continuous development of science is making possible<br />

the design of new materials with properties that were unthinkable<br />

a few years ago. The constant searching for lighter<br />

compounds, durable and compatible with the environment, has<br />

become one of the main goals of many researches today. In this<br />

sense, nanotechnology has quickly revolutionized the whole picture<br />

of current design of high added value materials due to the<br />

unique properties that those composites exhibit in fields as diverse<br />

as electronics, mechanics, optics or magnetism.<br />

Carbon nanotubes (CNTs) perfectly illustrate all the benefits<br />

that nanotechnology can bring, especially in the manufacture<br />

of polymer based nanocomposites. This is due to, among other<br />

reasons, their high electrical and thermal conductivity, which<br />

are transferred to the polymer, even using relatively small loads<br />

of CNTs. Many studies are being carried out to optimize the<br />

fabrication of polymer/CNT compounds, especially to improve the<br />

dispersion of CNTs within the polymer matrix.<br />

The Galician Automotive Technology Centre (CTAG), through its<br />

Engineering and Development department in the area of plastic<br />

products, seeks to explore and exploit all the inherent advantages<br />

of joining together polymer science and nanotechnology.<br />

Committed to the need to preserve respect for the environment<br />

by using, as far as possible, renewable sourced materials, CTAG<br />

currently develops compounds based on polylactic acid (PLA) and<br />

CNTs intended for diverse applications.<br />

Indeed, one of the most interesting properties of PLA/CNT<br />

composites from the standpoint of the practical applicability is<br />

their electrical conductivity. It is known that internal CNT networks<br />

are formed beyond a given threshold concentration of filler, the<br />

point at which a great increase of the electrical conductivity of the<br />

material appears. The electrical behaviour of the polymer also<br />

largely depends on the degree of alignment and dispersion of CNTs<br />

within the polymer matrix. PLA favours the dispersion of CNTs due<br />

to its polar character, and, in fact, PLA/CNT compounds exhibit<br />

in the order of five times the conductivity of PP/CNT composites<br />

(Figure 1).<br />

It has been shown that an external factor that can alter the<br />

disposition of CNTs, further produces conductivity changes in<br />

the sample. This behaviour allows, for example, the detection of<br />

impacts, by conductivity measurements, on pieces made of this<br />

material. The potential applications are vast, from the dynamic<br />

monitoring of structural damage of key parts of a car, to the<br />

localizing and counting of impacts on the surface of an airplane<br />

fuselage (Figure 2).<br />

Based on the same principle, we have developed prototypes<br />

of smart pedals that can detect emergency braking situations<br />

and activate adequate safety measures in case of an imminent<br />

18 bioplastics MAGAZINE [01/12] Vol. 7