bioplasticsMAGAZINE_1201

bioplasticsMAGAZINE_1201

bioplasticsMAGAZINE_1201

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Foam<br />

A<br />

B<br />

CO 2<br />

CO 2<br />

Photosynthesis/<br />

carbon fixation<br />

Photosynthesis/<br />

carbon fixation<br />

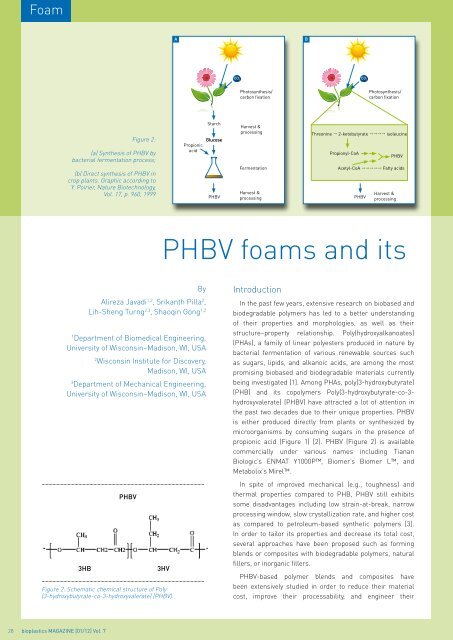

Figure 2:<br />

(a) Synthesis of PHBV by<br />

bacterial fermentation process;<br />

(b) Direct synthesis of PHBV in<br />

crop plants. Graphic according to<br />

Y. Poirier, Nature Biotechnology,<br />

Vol. 17, p. 960, 1999<br />

Propionic<br />

acid<br />

Starch<br />

Glucose<br />

PHBV<br />

Harvest &<br />

processing<br />

Fermentation<br />

Harvest &<br />

processing<br />

Threonine 2-ketobutyrate isoleucine<br />

Propionyl-CoA<br />

Acetyl-CoA Fatty acids<br />

PHBV<br />

PHBV<br />

Harvest &<br />

processing<br />

PHBV foams and its<br />

By<br />

Alireza Javadi 1,2 , Srikanth Pilla 2 ,<br />

Lih-Sheng Turng 2,3 , Shaoqin Gong 1,2<br />

1<br />

Department of Biomedical Engineering,<br />

University of Wisconsin–Madison, WI, USA<br />

2<br />

Wisconsin Institute for Discovery,<br />

Madison, WI, USA<br />

3<br />

Department of Mechanical Engineering,<br />

University of Wisconsin–Madison, WI, USA<br />

3HB<br />

PHBV<br />

3HV<br />

Figure 2: Schematic chemical structure of Poly<br />

(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV).<br />

Introduction<br />

In the past few years, extensive research on biobased and<br />

biodegradable polymers has led to a better understanding<br />

of their properties and morphologies, as well as their<br />

structure–property relationship. Poly(hydroxyalkanoates)<br />

(PHAs), a family of linear polyesters produced in nature by<br />

bacterial fermentation of various renewable sources such<br />

as sugars, lipids, and alkanoic acids, are among the most<br />

promising biobased and biodegradable materials currently<br />

being investigated [1]. Among PHAs, poly(3-hydroxybutyrate)<br />

(PHB) and its copolymers Poly(3-hydroxybutyrate-co-3-<br />

hydroxyvalerate) (PHBV) have attracted a lot of attention in<br />

the past two decades due to their unique properties. PHBV<br />

is either produced directly from plants or synthesized by<br />

microorganisms by consuming sugars in the presence of<br />

propionic acid (Figure 1) [2]. PHBV (Figure 2) is available<br />

commercially under various names including Tianan<br />

Biologic’s ENMAT Y1000P, Biomer’s Biomer L, and<br />

Metabolix’s Mirel.<br />

In spite of improved mechanical (e.g., toughness) and<br />

thermal properties compared to PHB, PHBV still exhibits<br />

some disadvantages including low strain-at-break, narrow<br />

processing window, slow crystallization rate, and higher cost<br />

as compared to petroleum-based synthetic polymers [3].<br />

In order to tailor its properties and decrease its total cost,<br />

several approaches have been proposed such as forming<br />

blends or composites with biodegradable polymers, natural<br />

fillers, or inorganic fillers.<br />

PHBV-based polymer blends and composites have<br />

been extensively studied in order to reduce their material<br />

cost, improve their processability, and engineer their<br />

28 bioplastics MAGAZINE [01/12] Vol. 7