bioplasticsMAGAZINE_1205

bioplasticsMAGAZINE_1205

bioplasticsMAGAZINE_1205

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Materials<br />

slaughterhouses, the animal waste rendering industry,<br />

and biodiesel production. Lipids from slaughterhouse<br />

waste are converted to fatty acid methylesters (FAMEs,<br />

biodiesel). FAMEs consisting of saturated fatty acids,<br />

generally constitute a fuel that has an elevated cold filter<br />

plugging point (CFPP) which can be disadvantageous<br />

in blends that exceed 20% by vol. FAMEs. In ANIMPOL,<br />

these saturated fractions are biotechnologically<br />

converted towards PHA biopolymers. As a by-product<br />

of the transesterification of lipids to FAMEs, crude<br />

glycerol phase (CGP) accrues in high quantities. CGP<br />

is also available as a carbon source for the production<br />

of catalytically active biomass and the production of<br />

low molecular mass PHA. This brings together waste<br />

producers from the animal processing industry with meat<br />

and bone meal (MBM) producers (rendering industry),<br />

the bio-fuel industry and polymer processing companies.<br />

This synergism results in value creation for all players.<br />

The basic scheme is illustrated in Fig. 3, whereas Fig. 4<br />

provides a rough estimation for the available amounts<br />

of raw materials in Europe and the amounts of PHA<br />

biopolyesters that are theoretically accessible therefrom.<br />

Major Objectives of ANIMPOL<br />

The project activities are based on a total of 13 main<br />

pillars:<br />

1. Design of an integrated industrial process for<br />

microbial mediated, cost-efficient production of<br />

biodegradable PHA biopolyesters, by starting from<br />

waste from slaughterhouses, rendering industry, and<br />

biodiesel production. These wastes are upgraded to<br />

renewable raw materials. After the end of the project,<br />

data should be available for designing a pilot scale<br />

production plant.<br />

2. Improvement of the quality of biodiesel by removal of<br />

its saturated fraction.<br />

3. Assessment of the raw materials (lipids from animal<br />

waste, saturated biodiesel fraction, surplus glycerol<br />

from biodiesel production) for the fermentation<br />

process by selected microbial strains accumulating<br />

structurally diversified PHAs.<br />

4. For improvement of microbial growth and quality, and<br />

the amount of the PHA produced, appropriate strains<br />

are studied, including recombinant gene expression<br />

or host cell genome modification. Microbial growth<br />

and the PHA production phase are established to be<br />

scaled-up for optimized production of structurally<br />

predefined PHAs. Protocols for controlled PHA<br />

production are developed aiming at reproducible<br />

product quality.<br />

6. Development of an environmentally safe, inexpensive<br />

and efficient downstream process for recovery and<br />

purification of PHAs.<br />

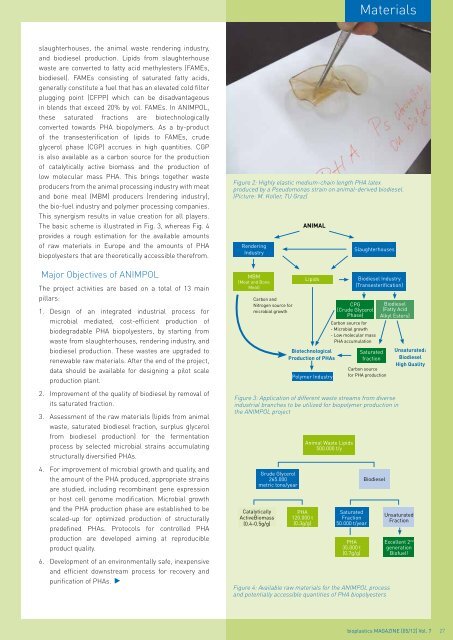

Figure 2: Highly elastic medium-chain length PHA latex<br />

produced by a Pseudomonas strain on animal-derived biodiesel.<br />

(Picture: M. Koller, TU Graz)<br />

Rendering<br />

Industry<br />

MBM<br />

(Meat and Bone<br />

Meal)<br />

Carbon and<br />

Nitrogen source for<br />

microbial growth<br />

Grude Glycerol<br />

265.000<br />

metric tons/year<br />

Catalytically<br />

ActiveBiomass<br />

(0.4-0.5g/g)<br />

ANIMAL<br />

Lipids<br />

Biotechnological<br />

Production of PHAs<br />

Polymer Industry<br />

PHA<br />

120.000 t<br />

(0.3g/g)<br />

Animal Waste Lipids<br />

500.000 t/y<br />

Saturated<br />

Fraction<br />

50.000 t/year<br />

PHA<br />

35.000 t<br />

(0.7g/g)<br />

Slaughterhouses<br />

Biodiesel Industry<br />

(Transesterification)<br />

CPG<br />

(Crude Glycerol<br />

Phase)<br />

Carbon source for<br />

- Microbial growth<br />

- Low molecular mass<br />

PHA accumulation<br />

Saturated<br />

fraction<br />

Carbon source<br />

for PHA production<br />

Biodiesel<br />

Figure 4: Available raw materials for the ANIMPOL process<br />

and potentially accessible quantities of PHA biopolyesters<br />

Biodiesel<br />

(Fatty Acid<br />

Alkyl Esters)<br />

Figure 3: Application of different waste streams from diverse<br />

industrial branches to be utilized for biopolymer production in<br />

the ANIMPOL project<br />

Unsaturated:<br />

Biodiesel<br />

High Quality<br />

Unsaturated<br />

Fraction<br />

Excellent 2 nd<br />

generation<br />

Biofuel!<br />

bioplastics MAGAZINE [05/12] Vol. 7 27