bioplasticsMAGAZINE_0905

bioplasticsMAGAZINE_0905

bioplasticsMAGAZINE_0905

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Paper Coating<br />

Improved<br />

Paper<br />

Coatings<br />

Article contributed by<br />

John T. Moore,<br />

Vice President- Business Development,<br />

DaniMer Scientific, Bainbridge, Georgia,<br />

USA<br />

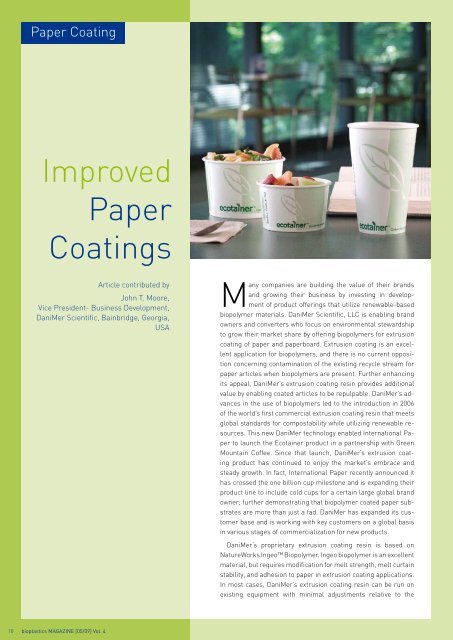

Many companies are building the value of their brands<br />

and growing their business by investing in development<br />

of product offerings that utilize renewable-based<br />

biopolymer materials. DaniMer Scientific, LLC is enabling brand<br />

owners and converters who focus on environmental stewardship<br />

to grow their market share by offering biopolymers for extrusion<br />

coating of paper and paperboard. Extrusion coating is an excellent<br />

application for biopolymers, and there is no current opposition<br />

concerning contamination of the existing recycle stream for<br />

paper articles when biopolymers are present. Further enhancing<br />

its appeal, DaniMer’s extrusion coating resin provides additional<br />

value by enabling coated articles to be repulpable. DaniMer’s advances<br />

in the use of biopolymers led to the introduction in 2006<br />

of the world’s first commercial extrusion coating resin that meets<br />

global standards for compostability while utilizing renewable resources.<br />

This new DaniMer technology enabled International Paper<br />

to launch the Ecotainer product in a partnership with Green<br />

Mountain Coffee. Since that launch, DaniMer’s extrusion coating<br />

product has continued to enjoy the market’s embrace and<br />

steady growth. In fact, International Paper recently announced it<br />

has crossed the one billion cup milestone and is expanding their<br />

product line to include cold cups for a certain large global brand<br />

owner; further demonstrating that biopolymer coated paper substrates<br />

are more than just a fad. DaniMer has expanded its customer<br />

base and is working with key customers on a global basis<br />

in various stages of commercialization for new products.<br />

DaniMer’s proprietary extrusion coating resin is based on<br />

NatureWorks Ingeo Biopolymer. Ingeo biopolymer is an excellent<br />

material, but requires modification for melt strength, melt curtain<br />

stability, and adhesion to paper in extrusion coating applications.<br />

In most cases, DaniMer’s extrusion coating resin can be run on<br />

existing equipment with minimal adjustments relative to the<br />

18 bioplastics MAGAZINE [05/09] Vol. 4