bioplasticsMAGAZINE_0905

bioplasticsMAGAZINE_0905

bioplasticsMAGAZINE_0905

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Basics<br />

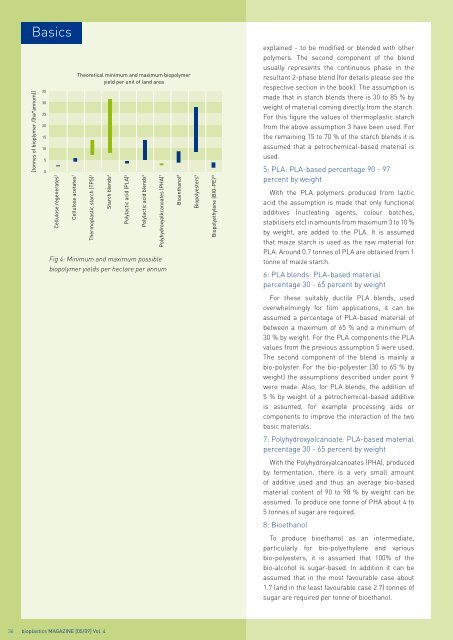

[tonnes of bioplymer /(ha*annum)]<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Cellulose regenerates 2<br />

Cellulose acetates 1<br />

Theoretical minimum and maximum biopolymer<br />

yield per unit of land area<br />

Thermoplastic starch (TPS) 3<br />

Starch blends 4<br />

Polylactic acid (PLA) 5<br />

Polylactic acid blends 6<br />

Polyhydroxyalkcanoates (PHA) 7<br />

Fig 4: Minimum and maximum possible<br />

biopolymer yields per hectare per annum<br />

Bioenthanol 8<br />

Biopolyesters 9<br />

Biopolyethylene (BIO-PE) 10<br />

explained - to be modified or blended with other<br />

polymers. The second component of the blend<br />

usually represents the continuous phase in the<br />

resultant 2-phase blend (for details please see the<br />

respective section in the book). The assumption is<br />

made that in starch blends there is 30 to 85 % by<br />

weight of material coming directly from the starch.<br />

For this figure the values of thermoplastic starch<br />

from the above assumption 3 have been used. For<br />

the remaining 15 to 70 % of the starch blends it is<br />

assumed that a petrochemical-based material is<br />

used.<br />

5: PLA: PLA-based percentage 90 - 97<br />

percent by weight<br />

With the PLA polymers produced from lactic<br />

acid the assumption is made that only functional<br />

additives (nucleating agents, colour batches,<br />

stabilisers etc) in amounts from maximum 3 to 10 %<br />

by weight, are added to the PLA. It is assumed<br />

that maize starch is used as the raw material for<br />

PLA. Around 0.7 tonnes of PLA are obtained from 1<br />

tonne of maize starch.<br />

6: PLA blends: PLA-based material<br />

percentage 30 - 65 percent by weight<br />

For these suitably ductile PLA blends, used<br />

overwhelmingly for film applications, it can be<br />

assumed a percentage of PLA-based material of<br />

between a maximum of 65 % and a minimum of<br />

30 % by weight. For the PLA components the PLA<br />

values from the previous assumption 5 were used.<br />

The second component of the blend is mainly a<br />

bio-polyster. For the bio-polyester (30 to 65 % by<br />

weight) the assumptions described under point 9<br />

were made. Also, for PLA blends, the addition of<br />

5 % by weight of a petrochemical-based additive<br />

is assumed, for example processing aids or<br />

components to improve the interaction of the two<br />

basic materials.<br />

7: Polyhydroxyalcanoate: PLA-based material<br />

percentage 30 - 65 percent by weight<br />

With the Polyhydroxyalcanoates (PHA), produced<br />

by fermentation, there is a very small amount<br />

of additive used and thus an average bio-based<br />

material content of 90 to 98 % by weight can be<br />

assumed. To produce one tonne of PHA about 4 to<br />

5 tonnes of sugar are required.<br />

8: Bioethanol<br />

To produce bioethanol as an intermediate,<br />

particularly for bio-polyethylene and various<br />

bio-polyesters, it is assumed that 100% of the<br />

bio-alcohol is sugar-based. In addition it can be<br />

assumed that in the most favourable case about<br />

1.7 (and in the least favourable case 2.7) tonnes of<br />

sugar are required per tonne of bioethanol.<br />

36 bioplastics MAGAZINE [05/09] Vol. 4