bioplasticsMAGAZINE_0902

bioplasticsMAGAZINE_0902

bioplasticsMAGAZINE_0902

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Opinion<br />

End of Life<br />

for Biodegradable &<br />

kg CO 2<br />

eq.<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

-10<br />

-20<br />

-30<br />

Attributional LCA<br />

Non Compostabel Cutlery<br />

Cutlery<br />

Organic Fraction<br />

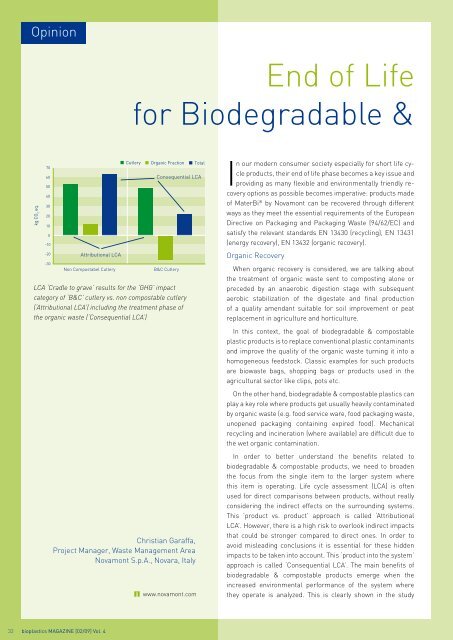

LCA ‘Cradle to grave’ results for the ‘GHG’ impact<br />

category of ‘B&C’ cutlery vs. non compostable cutlery<br />

(‘Attributional LCA’) including the treatment phase of<br />

the organic waste (‘Consequential LCA’)<br />

Christian Garaffa,<br />

Project Manager, Waste Management Area<br />

Novamont S.p.A., Novara, Italy<br />

www.novamont.com<br />

Total<br />

Consequential LCA<br />

B&C Cutlery<br />

In our modern consumer society especially for short life cycle<br />

products, their end of life phase becomes a key issue and<br />

providing as many flexible and environmentally friendly recovery<br />

options as possible becomes imperative: products made<br />

of MaterBi ® by Novamont can be recovered through different<br />

ways as they meet the essential requirements of the European<br />

Directive on Packaging and Packaging Waste (94/62/EC) and<br />

satisfy the relevant standards EN 13430 (recycling), EN 13431<br />

(energy recovery), EN 13432 (organic recovery).<br />

Organic Recovery<br />

When organic recovery is considered, we are talking about<br />

the treatment of organic waste sent to composting alone or<br />

preceded by an anaerobic digestion stage with subsequent<br />

aerobic stabilization of the digestate and final production<br />

of a quality amendant suitable for soil improvement or peat<br />

replacement in agriculture and horticulture.<br />

In this context, the goal of biodegradable & compostable<br />

plastic products is to replace conventional plastic contaminants<br />

and improve the quality of the organic waste turning it into a<br />

homogeneous feedstock. Classic examples for such products<br />

are biowaste bags, shopping bags or products used in the<br />

agricultural sector like clips, pots etc.<br />

On the other hand, biodegradable & compostable plastics can<br />

play a key role where products get usually heavily contaminated<br />

by organic waste (e.g. food service ware, food packaging waste,<br />

unopened packaging containing expired food). Mechanical<br />

recycling and incineration (where available) are difficult due to<br />

the wet organic contamination.<br />

In order to better understand the benefits related to<br />

biodegradable & compostable products, we need to broaden<br />

the focus from the single item to the larger system where<br />

this item is operating. Life cycle assessment (LCA) is often<br />

used for direct comparisons between products, without really<br />

considering the indirect effects on the surrounding systems.<br />

This ‘product vs. product’ approach is called ‘Attributional<br />

LCA’. However, there is a high risk to overlook indirect impacts<br />

that could be stronger compared to direct ones. In order to<br />

avoid misleading conclusions it is essential for these hidden<br />

impacts to be taken into account. This ‘product into the system’<br />

approach is called ‘Consequential LCA’. The main benefits of<br />

biodegradable & compostable products emerge when the<br />

increased environmental performance of the system where<br />

they operate is analyzed. This is clearly shown in the study<br />

32 bioplastics MAGAZINE [02/09] Vol. 4