MakerBot Educators Guidebook 3rd Edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MAKERBOT EDUCATORS GUIDEBOOK Chapter 4: Curriculum Project Ideas<br />

PAGE 72<br />

02<br />

List of items that need to be designed<br />

● Gripper Fingers<br />

● Phalanges<br />

Interact with objects and is capable of picking<br />

up and dropping objects.<br />

Responsible for expanding and retracting the<br />

gripper’s fingers.<br />

● Actuator<br />

● Core Connector<br />

Element that moves in a fixed up and down<br />

direction, and drives movement to the phalanges.<br />

Center element that joins the phalanges to the<br />

actuator.<br />

● Trident Housing<br />

● Nuts and Bolts<br />

An element that acts both as housing for the<br />

gripper and works with the gripper fingers and<br />

Used throughout the design to keep parts in<br />

place.<br />

secures the gripper fingers in place.<br />

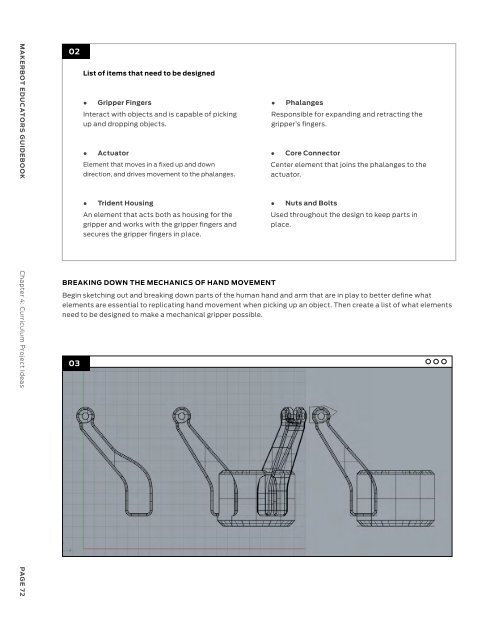

BREAKING DOWN THE MECHANICS OF HAND MOVEMENT<br />

Begin sketching out and breaking down parts of the human hand and arm that are in play to better define what<br />

elements are essential to replicating hand movement when picking up an object. Then create a list of what elements<br />

need to be designed to make a mechanical gripper possible.<br />

03<br />

PLAN AND DESIGN<br />

Using a preferred 3D modeling program (beginner-friendly modeling programs will work for this, too), begin thinking<br />

about how you will start designing the mechanical gripper. Will the actuator be designed first or the housing for the<br />

gripper? Is it best to start designing the biggest component first?<br />

Keep in mind there is no linear path for designing a prototype. It’s a cyclical process that develops over a period of time.<br />

04<br />

TIP:<br />

A good rule of thumb when designing something complex or with multiple parts is to break the designs down into<br />

simple shapes first, this will allow you to add design complexities later on.<br />

PRINT, REDESIGN AND PRINT AGAIN<br />

A mechanical gripper will require multiple printed parts. When preparing files to print, be sure to keep in mind how<br />

you orient the different parts on the build plate and if the orientation of parts will lend to stronger or weaker parts.<br />

The printing part of the process is where you’ll most likely find areas that need improvement - are the gripper fingers<br />

too long? Is there too much tolerance between the bolts and the parts? Keep these things in mind for the next<br />

iteration of this prototype.<br />

MAKERBOT EDUCATORS GUIDEBOOK Chapter 4: Curriculum Project Ideas<br />

PAGE 73