MakerBot Educators Guidebook 3rd Edition

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MAKERBOT EDUCATORS GUIDEBOOK Chapter 4: Curriculum Project Ideas<br />

PAGE 94<br />

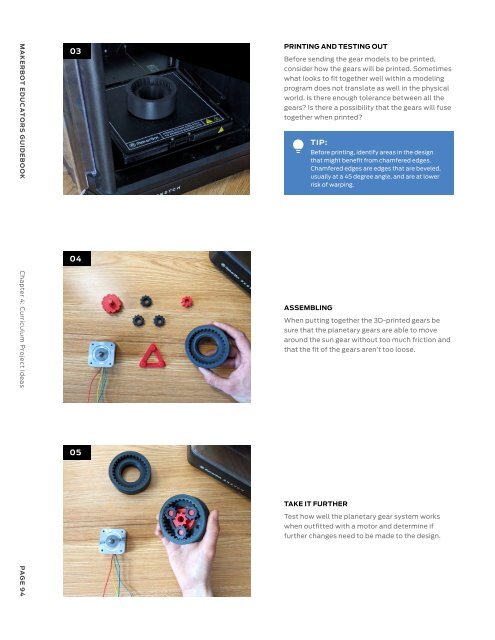

03<br />

04<br />

05<br />

PRINTING AND TESTING OUT<br />

Before sending the gear models to be printed,<br />

consider how the gears will be printed. Sometimes<br />

what looks to fit together well within a modeling<br />

program does not translate as well in the physical<br />

world. Is there enough tolerance between all the<br />

gears? Is there a possibility that the gears will fuse<br />

together when printed?<br />

TIP:<br />

ASSEMBLING<br />

Before printing, identify areas in the design<br />

that might benefit from chamfered edges.<br />

Chamfered edges are edges that are beveled,<br />

usually at a 45 degree angle, and are at lower<br />

risk of warping.<br />

When putting together the 3D-printed gears be<br />

sure that the planetary gears are able to move<br />

around the sun gear without too much friction and<br />

that the fit of the gears aren’t too loose.<br />

TAKE IT FURTHER<br />

Test how well the planetary gear system works<br />

when outfitted with a motor and determine if<br />

further changes need to be made to the design.<br />

Project: Snap-Together Robohand<br />

Project Category<br />

Part of the Lesson<br />

Design Difficulty<br />

LEARNING OBJECTIVES<br />

• Understand the mechanisms behind a robohand<br />

• Recognize the role 3D printing is playing in bringing down the costs<br />

of 3D prosthetics<br />

• Discuss how the existing design could be improved and what<br />

changes would be needed<br />

MAKERBOT EDUCATORS GUIDEBOOK Chapter 4: Curriculum Project Ideas<br />

PAGE 95