atw - International Journal for Nuclear Power | 05.2021

Description Ever since its first issue in 1956, the atw – International Journal for Nuclear Power has been a publisher of specialist articles, background reports, interviews and news about developments and trends from all important sectors of nuclear energy, nuclear technology and the energy industry. Internationally current and competent, the professional journal atw is a valuable source of information. www.nucmag.com

Description

Ever since its first issue in 1956, the atw – International Journal for Nuclear Power has been a publisher of specialist articles, background reports, interviews and news about developments and trends from all important sectors of nuclear energy, nuclear technology and the energy industry. Internationally current and competent, the professional journal atw is a valuable source of information.

www.nucmag.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>atw</strong> Vol. 66 (2021) | Issue 5 ı September<br />

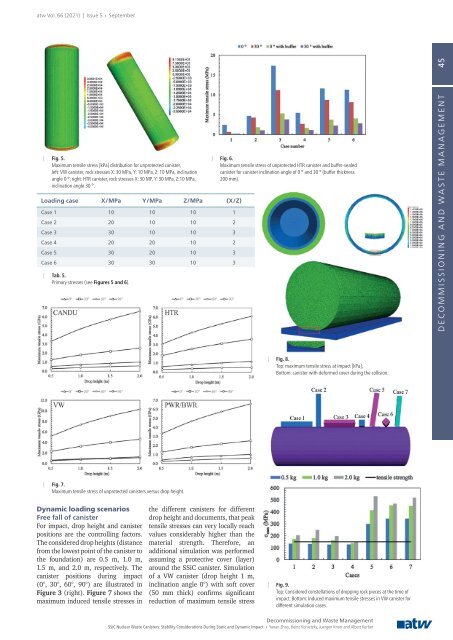

| Fig. 5.<br />

Maximum tensile stress [kPa] distribution <strong>for</strong> unprotected canister,<br />

left: VW canister, rock stresses X: 30 MPa, Y: 10 MPa, Z: 10 MPa, inclination<br />

angle 0 °; right: HTR canister, rock stresses X: 30 MP, Y: 30 MPa, Z:10 MPa,<br />

inclination angle 30 °.<br />

Loading case X/MPa Y/MPa Z/MPa (X/Z)<br />

Case 1 10 10 10 1<br />

Case 2 20 10 10 2<br />

Case 3 30 10 10 3<br />

Case 4 20 20 10 2<br />

Case 5 30 20 10 3<br />

Case 6 30 30 10 3<br />

| Tab. 5.<br />

Primary stresses (see Figures 5 and 6).<br />

| Fig. 6.<br />

Maximum tensile stress of unprotected HTR canister and buffer-sealed<br />

canister <strong>for</strong> canister inclination angle of 0 ° and 30 ° (buffer thickness<br />

200 mm).<br />

DECOMMISSIONING AND WASTE MANAGEMENT 45<br />

| Fig. 8.<br />

Top: maximum tensile stress at impact [kPa];<br />

Bottom: canister with de<strong>for</strong>med cover during the collision.<br />

| Fig. 7.<br />

Maximum tensile stress of unprotected canisters versus drop height.<br />

Dynamic loading scenarios<br />

Free fall of canister<br />

For impact, drop height and canister<br />

positions are the controlling factors.<br />

The considered drop heights (distance<br />

from the lowest point of the canister to<br />

the foundation) are 0.5 m, 1.0 m,<br />

1.5 m, and 2.0 m, respectively. The<br />

canister positions during impact<br />

(0°, 30°, 60°, 90°) are illustrated in<br />

Figure 3 (right). Figure 7 shows the<br />

maximum induced tensile stresses in<br />

the different canisters <strong>for</strong> different<br />

drop height and documents, that peak<br />

tensile stresses can very locally reach<br />

values considerably higher than the<br />

material strength. There<strong>for</strong>e, an<br />

additional simulation was per<strong>for</strong>med<br />

assuming a protective cover (layer)<br />

around the SSiC canister. Simulation<br />

of a VW canister (drop height 1 m,<br />

inclination angle 0°) with soft cover<br />

(50 mm thick) confirms significant<br />

reduction of maximum tensile stress<br />

| Fig. 9.<br />

Top: Considered constellations of dropping rock pieces at the time of<br />

impact; Bottom: Induced maximum tensile stresses in VW canister <strong>for</strong><br />

different simulation cases.<br />

Decommissioning and Waste Management<br />

SSiC <strong>Nuclear</strong> Waste Canisters: Stability Considerations During Static and Dynamic Impact ı Yanan Zhao, Heinz Konietzky, Juergen Knorr and Albert Kerber