issue 05/2021

Highlights: Fibres, Textiles, Nonwovens Biocomposites Basics: CO2-based plastics

Highlights:

Fibres, Textiles, Nonwovens

Biocomposites

Basics: CO2-based plastics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Green2Black<br />

developing biobased acrylonitrile<br />

By:<br />

S. Schonauer, T. Röding & T. Gries<br />

Institut für Textiltechnik of RWTH Aachen University, Aachen, Germany<br />

Due to the transition towards renewable resources as<br />

well as politically set goals by 2030, the industry is facing<br />

fundamental changes in energy supply and its raw<br />

material base. This bears the risk of shortages, rising prices,<br />

or incompatibility with established processes. It therefore<br />

makes sense to develop processes with which fossil-based<br />

basic materials can gradually be replaced by renewable ones.<br />

The ITA of RWTH Aachen University is currently in the process<br />

of developing such a drop-in solution for the basic chemical<br />

acrylonitrile (ACN).<br />

ACN is one of the most important basic chemicals or<br />

monomers for the plastics industry worldwide. The demand in<br />

the international context lies around 6 million tonnes per year<br />

with a slight trend upwards [1, 2]. Currently, ACN is produced<br />

within the petrochemical industry. This means that ACN is<br />

produced on the basis of mineral oil. Its use as a raw material<br />

entails not only various risks for society and nature but is also<br />

not consistent with present ecological goals. Alternative initial<br />

raw materials that result in a sustainable process chain are a<br />

promising solution for tackling these problems. [3]<br />

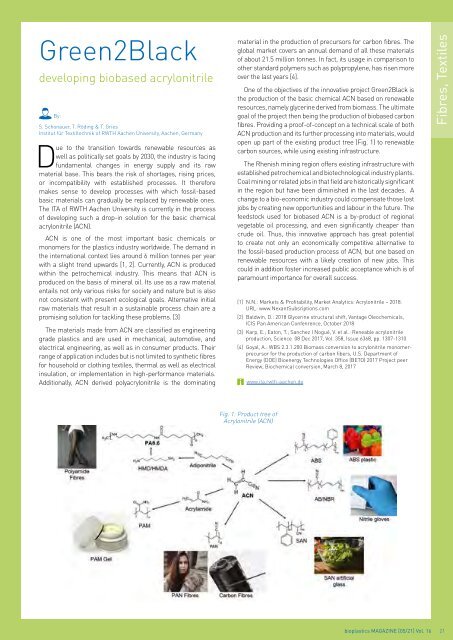

The materials made from ACN are classified as engineering<br />

grade plastics and are used in mechanical, automotive, and<br />

electrical engineering, as well as in consumer products. Their<br />

range of application includes but is not limited to synthetic fibres<br />

for household or clothing textiles, thermal as well as electrical<br />

insulation, or implementation in high-performance materials.<br />

Additionally, ACN derived polyacrylonitrile is the dominating<br />

material in the production of precursors for carbon fibres. The<br />

global market covers an annual demand of all these materials<br />

of about 21.5 million tonnes. In fact, its usage in comparison to<br />

other standard polymers such as polypropylene, has risen more<br />

over the last years [4].<br />

One of the objectives of the innovative project Green2Black is<br />

the production of the basic chemical ACN based on renewable<br />

resources, namely glycerine derived from biomass. The ultimate<br />

goal of the project then being the production of biobased carbon<br />

fibres. Providing a proof-of-concept on a technical scale of both<br />

ACN production and its further processing into materials, would<br />

open up part of the existing product tree (Fig. 1) to renewable<br />

carbon sources, while using existing infrastructure.<br />

The Rhenish mining region offers existing infrastructure with<br />

established petrochemical and biotechnological industry plants.<br />

Coal mining or related jobs in that field are historically significant<br />

in the region but have been diminished in the last decades. A<br />

change to a bio-economic industry could compensate those lost<br />

jobs by creating new opportunities and labour in the future. The<br />

feedstock used for biobased ACN is a by-product of regional<br />

vegetable oil processing, and even significantly cheaper than<br />

crude oil. Thus, this innovative approach has great potential<br />

to create not only an economically competitive alternative to<br />

the fossil-based production process of ACN, but one based on<br />

renewable resources with a likely creation of new jobs. This<br />

could in addition foster increased public acceptance which is of<br />

paramount importance for overall success.<br />

[1] N.N.: Markets & Profitability, Market Analytics: Acrylonitrile – 2018.<br />

URL: www.NexantSubsriptions.com<br />

[2] Baldwin, D.: 2018 Glycerine structural shift, Vantage Oleochemicals,<br />

ICIS Pan American Confenrence, October 2018<br />

[3] Karp, E.; Eaton, T.; Sanchez I Nogué, V. et al.: Reneable acrylonitrile<br />

production, Science 08 Dec 2017, Vol. 358, Issue 6368, pp. 1307-1310<br />

[4] Goyal, A.: WBS 2.3.1.200 Biomass conversion to acrylonitrile monomerprecursor<br />

for the production of carbon fibers, U.S. Department of<br />

Energy (DOE) Bioenergy Technologies Office (BETO) 2017 Project peer<br />

Review, Biochemical conversion, March 8, 2017<br />

www.ita.rwth-aachen.de<br />

Fibres, Textiles textiles<br />

Fig. 1: Product tree of<br />

Acrylonitrile (ACN)<br />

bioplastics MAGAZINE [<strong>05</strong>/21] Vol. 16 21