Issue 06/2021

Highlights: Coating Films, Flexibles, Bags Basics: Cellulose based bioplastics

Highlights:

Coating

Films, Flexibles, Bags

Basics: Cellulose based bioplastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Clean-up ships fuelled<br />

by garbage<br />

Millions of tonnes of synthetic plastics are released to<br />

the environment each year. Of this, a fraction ends<br />

up in one of several oceanic gyres, natural locations<br />

where the currents tend to accumulate floating debris –<br />

including plastics. The largest and best known of these is<br />

the Great Pacific Garbage Patch (GPGP), which is estimated<br />

to cover an area roughly the size of the state of Texas (or<br />

France), and which seems to be increasing in size over time.<br />

Removing this plastic from the oceanic gyres has promise<br />

to return the ocean to a more pristine state and alleviate the<br />

associated burden on wildlife and the food chain. Current<br />

methods to remove this plastic use a boom system to<br />

concentrate the plastic and a ship to harvest it and return to<br />

port to unload the plastic cargo and refuel [1].<br />

Plastic is a natural energy carrier, which suggests the<br />

question: is there enough energy embodied in the plastic to<br />

power the ship and eliminate or reduce the need to return to<br />

port? If so, then can a process be devised to convert plastic<br />

into a form of fuel appropriate for modern diesel engines<br />

that are used to power ships?<br />

Thermodynamic analysis of the energy available in plastics<br />

answered the first question –<br />

yes, there is enough energy in<br />

the ocean plastics, provided that<br />

they are first concentrated using A<br />

booms and that the ship is small<br />

and efficient enough to minimize<br />

its fuel consumption.<br />

The next question was<br />

answered by designing a<br />

process to convert plastics into<br />

a liquid fuel precursor. The most<br />

important step of the process is a<br />

high-temperature reaction called<br />

hydrothermal liquefaction or<br />

HTL. HTL depolymerizes plastics<br />

at high temperature (300–550 °C)<br />

and high pressure (250–300<br />

bar), thereby converting it into a<br />

liquid form. Oil yields from HTL<br />

are typically >90 % even in the<br />

absence of catalysts and, unlike<br />

pyrolysis, yields of solid byproducts<br />

– which would need to<br />

be stored or burned in a special<br />

combustor – are less than 5, thus<br />

conferring certain comparative<br />

advantages to HTL.<br />

Current data on the GPGP<br />

indicates that it contains mainly<br />

polyethylene and polypropylene,<br />

a mixture that is especially<br />

Great Pacific<br />

Garbage Patch<br />

C<br />

~ 1900 km<br />

San Francisco Port<br />

Current with Plastic<br />

Boom 600 m<br />

appropriate for HTL. By-products include a gas that might<br />

be used as a cooking fuel; a solid that could be burned on<br />

board or stored; and process water that is cleaned prior to<br />

release. Further analysis indicated that the use of plasticderived<br />

fuels could reduce fuel consumption, and effectively<br />

eliminate fossil fuel use. The HTL derived fuel could be<br />

termed blue diesel, to reference its marine origin and in<br />

contrast with both traditional marine diesel and green<br />

diesel, derived from land-based renewable resources. The<br />

full feasibility study is available for free online (link below<br />

[1]). Future work will construct the process and test it at<br />

pilot-scale for realistic feeds, to ultimately transition to<br />

shipboard use. AT<br />

[1] Belden, E.R.; Kazantzis, N.K.; Reddy,C.M.; Kite-Powell, H; Timko,M.T.;<br />

Italiani, E.; Herschbach D.R.: Thermodynamic feasibility of shipboard<br />

conversion of marine plastics to blue diesel for self-powered ocean<br />

cleanup; https://doi.org/10.1073/pnas.2107250118<br />

www.wpi.edu<br />

California<br />

0.5 knots<br />

B<br />

D<br />

Current 14 cm s -1<br />

Boom Array System<br />

Reactor<br />

15 knots<br />

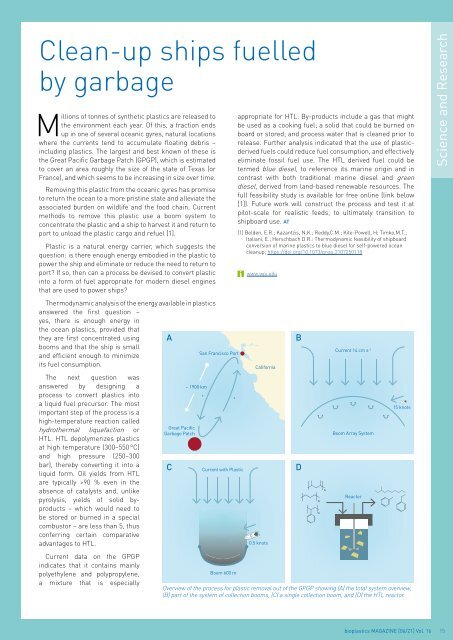

Overview of the process for plastic removal out of the GPGP showing (A) the total system overview,<br />

(B) part of the system of collection booms, (C) a single collection boom, and (D) the HTL reactor.<br />

Science and Research<br />

San Francisco Port<br />

Current bioplastics 14 cm s MAGAZINE [<strong>06</strong>/21] Vol. 16 15<br />

-1