Issue 06/2021

Highlights: Coating Films, Flexibles, Bags Basics: Cellulose based bioplastics

Highlights:

Coating

Films, Flexibles, Bags

Basics: Cellulose based bioplastics

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

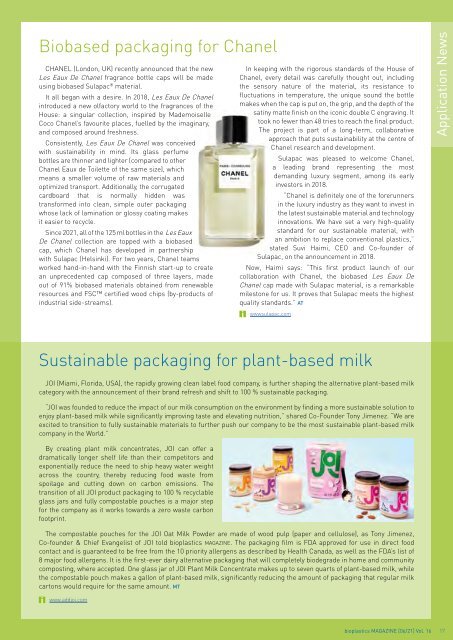

Biobased packaging for Chanel<br />

CHANEL (London, UK) recently announced that the new<br />

Les Eaux De Chanel fragrance bottle caps will be made<br />

using biobased Sulapac ® material.<br />

It all began with a desire. In 2018, Les Eaux De Chanel<br />

introduced a new olfactory world to the fragrances of the<br />

House: a singular collection, inspired by Mademoiselle<br />

Coco Chanel’s favourite places, fuelled by the imaginary,<br />

and composed around freshness.<br />

Consistently, Les Eaux De Chanel was conceived<br />

with sustainability in mind. Its glass perfume<br />

bottles are thinner and lighter (compared to other<br />

Chanel Eaux de Toilette of the same size), which<br />

means a smaller volume of raw materials and<br />

optimized transport. Additionally, the corrugated<br />

cardboard that is normally hidden was<br />

transformed into clean, simple outer packaging<br />

whose lack of lamination or glossy coating makes<br />

it easier to recycle.<br />

Since <strong>2021</strong>, all of the 125 ml bottles in the Les Eaux<br />

De Chanel collection are topped with a biobased<br />

cap, which Chanel has developed in partnership<br />

with Sulapac (Helsinki). For two years, Chanel teams<br />

worked hand-in-hand with the Finnish start-up to create<br />

an unprecedented cap composed of three layers, made<br />

out of 91% biobased materials obtained from renewable<br />

resources and FSC certified wood chips (by-products of<br />

industrial side-streams).<br />

In keeping with the rigorous standards of the House of<br />

Chanel, every detail was carefully thought out, including<br />

the sensory nature of the material, its resistance to<br />

fluctuations in temperature, the unique sound the bottle<br />

makes when the cap is put on, the grip, and the depth of the<br />

satiny matte finish on the iconic double C engraving. It<br />

took no fewer than 48 tries to reach the final product.<br />

The project is part of a long-term, collaborative<br />

approach that puts sustainability at the centre of<br />

Chanel research and development.<br />

Sulapac was pleased to welcome Chanel,<br />

a leading brand representing the most<br />

demanding luxury segment, among its early<br />

investors in 2018.<br />

“Chanel is definitely one of the forerunners<br />

in the luxury industry as they want to invest in<br />

the latest sustainable material and technology<br />

innovations. We have set a very high-quality<br />

standard for our sustainable material, with<br />

an ambition to replace conventional plastics,”<br />

stated Suvi Haimi, CEO and Co-founder of<br />

Sulapac, on the announcement in 2018.<br />

Now, Haimi says: “This first product launch of our<br />

collaboration with Chanel, the biobased Les Eaux De<br />

Chanel cap made with Sulapac material, is a remarkable<br />

milestone for us. It proves that Sulapac meets the highest<br />

quality standards.” AT<br />

wwwsulapac.com<br />

Application News<br />

Sustainable packaging for plant-based milk<br />

JOI (Miami, Florida, USA), the rapidly growing clean label food company, is further shaping the alternative plant-based milk<br />

category with the announcement of their brand refresh and shift to 100 % sustainable packaging.<br />

“JOI was founded to reduce the impact of our milk consumption on the environment by finding a more sustainable solution to<br />

enjoy plant-based milk while significantly improving taste and elevating nutrition,” shared Co-Founder Tony Jimenez. “We are<br />

excited to transition to fully sustainable materials to further push our company to be the most sustainable plant-based milk<br />

company in the World.”<br />

By creating plant milk concentrates, JOI can offer a<br />

dramatically longer shelf life than their competitors and<br />

exponentially reduce the need to ship heavy water weight<br />

across the country, thereby reducing food waste from<br />

spoilage and cutting down on carbon emissions. The<br />

transition of all JOI product packaging to 100 % recyclable<br />

glass jars and fully compostable pouches is a major step<br />

for the company as it works towards a zero waste carbon<br />

footprint.<br />

The compostable pouches for the JOI Oat Milk Powder are made of wood pulp (paper and cellulose), as Tony Jimenez,<br />

Co-founder & Chief Evangelist of JOI told bioplastics MAGAZINE. The packaging film is FDA approved for use in direct food<br />

contact and is guaranteed to be free from the 10 priority allergens as described by Health Canada, as well as the FDA’s list of<br />

8 major food allergens. It is the first-ever dairy alternative packaging that will completely biodegrade in home and community<br />

composting, where accepted. One glass jar of JOI Plant Milk Concentrate makes up to seven quarts of plant-based milk, while<br />

the compostable pouch makes a gallon of plant-based milk, significantly reducing the amount of packaging that regular milk<br />

cartons would require for the same amount. MT<br />

www.addjoi.com<br />

bioplastics MAGAZINE [<strong>06</strong>/21] Vol. 16 17