Issue 06/2021

Highlights: Coating Films, Flexibles, Bags Basics: Cellulose based bioplastics

Highlights:

Coating

Films, Flexibles, Bags

Basics: Cellulose based bioplastics

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Materials<br />

Fill the gap, not the landfill<br />

Governments and institutions have been scrambling<br />

to rectify the global environmental disaster caused<br />

by the accumulation of plastic waste. This plastic<br />

waste comes in macroscopic forms such as bottles, plastic<br />

bags, and polyester clothing. In the best-case scenario, it is<br />

regulated and dumped into overcrowded landfills or in the<br />

worst case, it escapes into the open environment as litter<br />

directly endangering the health and safety of wildlife and<br />

local populations [1]. Alarmingly an even more insidious<br />

type of plastic, ‘microplastic’, or plastic waste so small it<br />

is invisible to the eye, has been making headlines as it can<br />

be found in the water, soil, and even inside of our bodies [1].<br />

The steps being taken to address this issue focus<br />

on banning specific single-use plastic items or their<br />

substitution with more sustainable alternatives (reusable,<br />

recyclable, or compostable). This is part of an overall shift<br />

from a linear economy to a circular economy. To accelerate<br />

this change, governments have passed their own single-use<br />

plastics bans or have committed themselves to initiatives<br />

such as the New Plastics Economy, Global Commitment led<br />

by the Ellen Macarthur Foundation (EMF) [2].<br />

The goal is to ‘build a circular economy around plastics’<br />

by initially setting strict goals around certain single-use<br />

plastic items for 2025. With these measures in place there<br />

is an incentive for building a future where plastics are either<br />

replaced and or are fully circular. In the meantime, there are<br />

still large gaps that need to be filled by addressing singleuse-items<br />

that fall outside of traditional packaging or<br />

consumer products. Personal protective equipment, sterile<br />

items, and chemically contaminated consumables are<br />

items that are not easily substituted with other materials as<br />

these applications require high-performance and durability<br />

that only plastics can currently provide. Additionally, these<br />

items have recyclability challenges due to contamination or<br />

are used in remote environments (such as for agricultural<br />

applications) where they cannot be efficiently collected [3].<br />

These items are usually landfilled or incinerated, both of<br />

which do not fall under the Ellen Macarthur Foundation’s<br />

definition of circular [2]. The current COVID-19 pandemic<br />

has only exacerbated this type of waste due to the significant<br />

increase of personal protective equipment (PPE) and sterile<br />

consumables. Sources have cited that over four million<br />

tonnes of polypropylene waste from PPE have been disposed<br />

of over the course of the pandemic and will continue to grow<br />

[3]. These hard to remediate items are important and will<br />

not disappear.<br />

A solution is to develop innovative materials and circular<br />

product design. Biodegradable and compostable plastics<br />

are viable options to tackle this problem, as they have<br />

the potential to match the performance needed for these<br />

applications [4]. On the other hand, some of these plastics<br />

display incomplete degradation ultimately leading to<br />

microplastics. To elevate degradable plastics into truly<br />

sustainable and viable alternatives major improvements<br />

and innovations are needed.<br />

Scientists have been designing materials that allow rapid<br />

degradation – much more efficient than their traditional<br />

counterparts. In addition, the onset of degradation can<br />

be controlled or triggered. In recent years, triggered<br />

degradation plastics that utilise hydrolytic enzymes<br />

have created attention in the media due to their speed of<br />

degradation and broad applicability. The idea of enzymes<br />

that can degrade plastic, particularly polyesters, is not new<br />

as the entire concept of microbial biodegradation hinges on<br />

this process.<br />

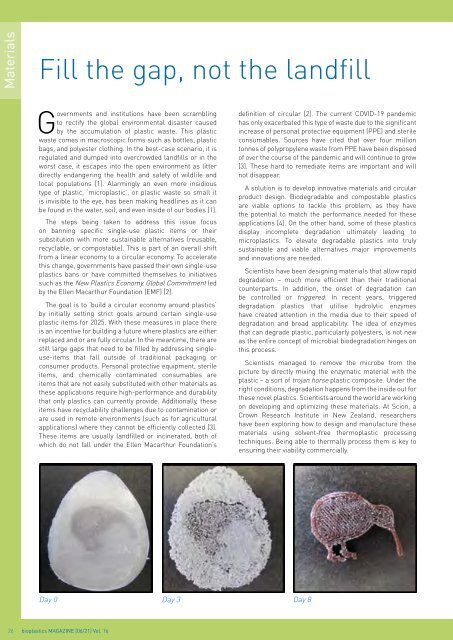

Scientists managed to remove the microbe from the<br />

picture by directly mixing the enzymatic material with the<br />

plastic – a sort of trojan horse plastic composite. Under the<br />

right conditions, degradation happens from the inside out for<br />

these novel plastics. Scientists around the world are working<br />

on developing and optimizing these materials. At Scion, a<br />

Crown Research Institute in New Zealand, researchers<br />

have been exploring how to design and manufacture these<br />

materials using solvent-free thermoplastic processing<br />

techniques. Being able to thermally process them is key to<br />

ensuring their viability commercially.<br />

Day 0 Day 3 Day 8<br />

26 bioplastics MAGAZINE [<strong>06</strong>/21] Vol. 16