National Hardwood Magazine - March 2022

The latest issue of National Hardwood Magazine features stories on Elipticon Wood Products, The Beasley Group, an update on the economy and much more.

The latest issue of National Hardwood Magazine features stories on Elipticon Wood Products, The Beasley Group, an update on the economy and much more.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Hazlehurst, GA–The Beasley Group, headquartered<br />

here, is a vertically integrated forest products<br />

company, which starts with growing the trees to<br />

shipping the lumber. The company’s story is a story of<br />

rapid growth and success built on family, faith, and foresight<br />

over the last 50 plus years. From the beginning the<br />

company has grown into an organization operating six<br />

different business segments utilizing the entire tree.<br />

In 1968, the founder of Beasley Timber, Rabun Beasley,<br />

decided he wanted to make a career change from<br />

selling insurance and made the decision to move into the<br />

logging business selling timber. In the beginning,<br />

Mr. Rabun and his wife, Jo Claxton Beasley,<br />

operated the company and built lifelong<br />

relationships with others in the industry, many<br />

that the company still enjoys today. To look at<br />

the business today it is hard to believe it all<br />

started from a few chainsaws and a log truck.<br />

Mr. Rabun developed a harvesting method<br />

used in low lying areas that eventually became<br />

known as “Swamp Logging.” Today, this area<br />

of the company still operates as Beasley Timber<br />

Company, led by family member Zachary<br />

Johnson. Other operations within this division<br />

include Logistics, Logging and Timber Management.<br />

In 1997 the shuttered Louisiana Pacific<br />

sawmill located in Hazlehurst was purchased<br />

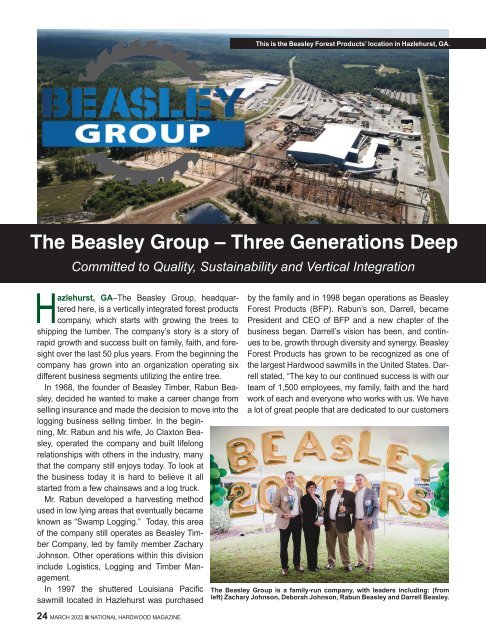

This is the Beasley Forest Products’ location in Hazlehurst, GA.<br />

The Beasley Group – Three Generations Deep<br />

Committed to Quality, Sustainability and Vertical Integration<br />

by the family and in 1998 began operations as Beasley<br />

Forest Products (BFP). Rabun’s son, Darrell, became<br />

President and CEO of BFP and a new chapter of the<br />

business began. Darrell’s vision has been, and continues<br />

to be, growth through diversity and synergy. Beasley<br />

Forest Products has grown to be recognized as one of<br />

the largest <strong>Hardwood</strong> sawmills in the United States. Darrell<br />

stated, “The key to our continued success is with our<br />

team of 1,500 employees, my family, faith and the hard<br />

work of each and everyone who works with us. We have<br />

a lot of great people that are dedicated to our customers<br />

The Beasley Group is a family-run company, with leaders including: (from<br />

left) Zachary Johnson, Deborah Johnson, Rabun Beasley and Darrell Beasley.<br />

and to our <strong>Hardwood</strong> and softwood business.”<br />

The Beasley Group continues to be a family-owned<br />

business moving into the third generation. In addition<br />

to several of Darrell’s children, Grant, Jordon, Truss,<br />

Christin and Daniel, his sister, Deborah Johnson, and<br />

her husband Zachary also have key roles in the ongoing<br />

business success.<br />

In 2018 a major woodyard and sawmill expansion and<br />

optimization project launched, and the new operations<br />

started up in mid-year 2020. This expansion allows BFP<br />

to utilize the latest optimization equipment, allowing the<br />

operation to more than double the previous board footage<br />

produced in a more cost-effective and efficient manner.<br />

With the additional volume, more jobs were created<br />

throughout the value stream from logs to lumber.<br />

The manufacturing segment includes five sawmills located<br />

in Hazlehurst, GA (2), Sandersville, GA, Denmark,<br />

SC and Ashland, WI. These operations are very diverse<br />

in the species used and the products produced. Nine<br />

different species are cut – Ash, Red Oak, White Oak,<br />

Poplar, Hickory, Maple, Cypress, mixed <strong>Hardwood</strong> and<br />

pine. The company serves many different domestic and<br />

worldwide customers by supplying grade lumber, pallet<br />

stock, cross/switch ties, and access mats. Products are<br />

Grade lumber is stored in the distribution center.<br />

The Beasley Planer/Sorter and Distribution Building takes in approximately<br />

300,000 square feet.<br />

“The key to our continued<br />

success is with our team of<br />

1,500 employees, my family, faith<br />

and the hard work of each and<br />

everyone who works with us. We<br />

have a lot of great people that are<br />

dedicated to our customers and<br />

to our <strong>Hardwood</strong> and softwood<br />

business.<br />

24 MARCH <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE MARCH <strong>2022</strong> n NATIONAL HARDWOOD MAGAZINE 25<br />

“<br />

–Darrell Beasley,<br />

President and CEO,<br />

Beasley Forest Products<br />

sold kiln-dried, green, and heat-treated.<br />

Other operations within the manufacturing segment<br />

are Beasley Flooring, producing both solid and engi-<br />

Please turn to page 34<br />

Here is an example of Beasley’s mats being utilized in the field.<br />

The sales team includes: (from left) Linwood Truitt, John Stevenson,<br />

Brandon Cox, Ryan Collins and Truss Beasley. Not pictured:<br />

Ray Turner.