Issue 04/2022

Highlights: Blow Moulding / Bottle Applications Polyurethanes / Elastomers Basics: FDCA & PEF

Highlights:

Blow Moulding / Bottle Applications

Polyurethanes / Elastomers

Basics:

FDCA & PEF

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Elastomers<br />

% RS through STEP 1 (ricinolenic acid derivates)<br />

% RS through STEP 2 (ricinolenic acid derivates and bio BDO)<br />

33% 49%<br />

30% 51%<br />

25% 49%<br />

19%46%<br />

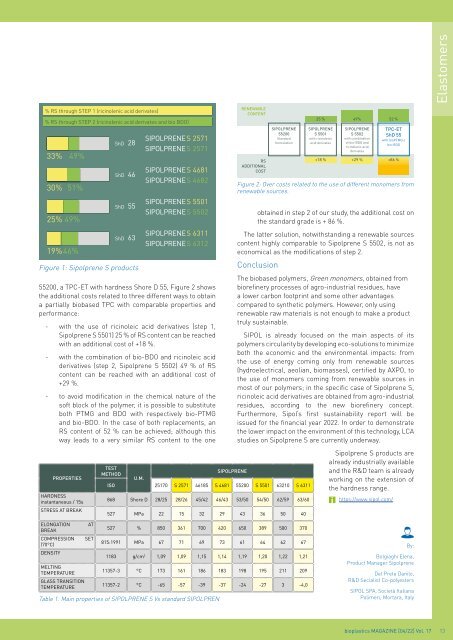

55200, a TPC-ET with hardness Shore D 55, Figure 2 shows<br />

the additional costs related to three different ways to obtain<br />

a partially biobased TPC with comparable properties and<br />

performance:<br />

- with the use of ricinoleic acid derivatives (step 1,<br />

Sipolprene S 5501) 25 % of RS content can be reached<br />

with an additional cost of +18 %.<br />

- with the combination of bio-BDO and ricinoleic acid<br />

derivatives (step 2, Sipolprene S 5502) 49 % of RS<br />

content can be reached with an additional cost of<br />

+29 %.<br />

- to avoid modification in the chemical nature of the<br />

soft block of the polymer, it is possible to substitute<br />

both PTMG and BDO with respectively bio-PTMG<br />

and bio-BDO. In the case of both replacements, an<br />

RS content of 52 % can be achieved; although this<br />

way leads to a very similar RS content to the one<br />

PROPERTIES<br />

HARDNESS<br />

instantaneous / 15s<br />

STRESS AT BREAK<br />

ShD 28<br />

ShD 46<br />

ShD 55<br />

ShD 63<br />

Figure 1: Sipolprene S products<br />

SIPOLPRENES 2571<br />

SIPOLPRENES 2571<br />

SIPOLPRENES 4681<br />

SIPOLPRENES 4682<br />

SIPOLPRENES 5501<br />

SIPOLPRENES 5502<br />

SIPOLPRENES 6311<br />

SIPOLPRENES 6312<br />

RENEWABLE<br />

CONTENT<br />

RS<br />

ADDITIONAL<br />

COST<br />

SIPOLPRENE<br />

55200<br />

Standard<br />

formulation<br />

TEST<br />

SIPOLPRENE<br />

METHOD<br />

U.M.<br />

ISO 25170 S 2571 46185 S 4681 55200 S 5501 63210 S 6311<br />

868 Shore D 28/25 28/26 45/42 46/43 53/50 54/50 62/59 63/60<br />

527 MPa 22 15 32 29 43 36 50 40<br />

25 %<br />

SIPOLPRENE<br />

S 5501<br />

with ricinolenic<br />

acid derivates<br />

+18 %<br />

SIPOLPRENE<br />

S 5502<br />

with combination<br />

of bio-BDO and<br />

ricinolenic acid<br />

derivates<br />

+29 %<br />

Figure 2: Over costs related to the use of different monomers from<br />

renewable sources.<br />

obtained in step 2 of our study, the additional cost on<br />

the standard grade is + 86 %.<br />

The latter solution, notwithstanding a renewable sources<br />

content highly comparable to Sipolprene S 5502, is not as<br />

economical as the modifications of step 2.<br />

Conclusion<br />

The biobased polymers, Green monomers, obtained from<br />

biorefinery processes of agro-industrial residues, have<br />

a lower carbon footprint and some other advantages<br />

compared to synthetic polymers. However, only using<br />

renewable raw materials is not enough to make a product<br />

truly sustainable.<br />

SIPOL is already focused on the main aspects of its<br />

polymers circularity by developing eco-solutions to minimize<br />

both the economic and the environmental impacts: from<br />

the use of energy coming only from renewable sources<br />

(hydroelectrical, aeolian, biomasses), certified by AXPO, to<br />

the use of monomers coming from renewable sources in<br />

most of our polymers; in the specific case of Sipolprene S,<br />

ricinoleic acid derivatives are obtained from agro-industrial<br />

residues, according to the new biorefinery concept.<br />

Furthermore, Sipol’s first sustainability report will be<br />

issued for the financial year <strong>2022</strong>. In order to demonstrate<br />

the lower impact on the environment of this technology, LCA<br />

studies on Sipolprene S are currently underway.<br />

49%<br />

Sipolprene S products are<br />

already industrially available<br />

and the R&D team is already<br />

working on the extension of<br />

the hardness range.<br />

https://www.sipol.com/<br />

52 %<br />

TPC-ET<br />

ShD 55<br />

with bioPTMG e<br />

bio-BDO<br />

+86 %<br />

ELONGATION <br />

BREAK<br />

COMPRESSION <br />

(70°C)<br />

DENSITY<br />

MELTING<br />

TEMPERATURE<br />

GLASS TRANSITION<br />

TEMPERATURE<br />

AT<br />

SET<br />

527 % 850 361 700 420 650 389 500 370<br />

815:1991 MPa 67 71 69 73 61 64 62 67<br />

1183 g/cm 3 1,09 1,09 1,15 1,14 1,19 1,20 1,22 1,21<br />

11357-3 °C 173 161 186 183 198 195 211 209<br />

11357-2 °C -65 -57 -39 -37 -24 -27 3 -4,0<br />

Table 1: Main properties of SIPOLPRENE S Vs standard SIPOLPREN<br />

By:<br />

Bolgiaghi Elena,<br />

Product Manager Sipolprene<br />

Del Prete Danilo,<br />

R&D Secialist Co-polyesters<br />

SIPOL SPA, Società Italiana<br />

Polimeri, Mortara, Italy<br />

bioplastics MAGAZINE [<strong>04</strong>/22] Vol. 17 13