The Softwood Forest Products Buyer - November/December 2022

In the latest issue of the Softwood Forest Products Buyer, see photos from the latest NELMA, Global Buyers Mission and LAT conferences, plus stories about Sawmill Surplus LLC and Western Red Cedar.

In the latest issue of the Softwood Forest Products Buyer, see photos from the latest NELMA, Global Buyers Mission and LAT conferences, plus stories about Sawmill Surplus LLC and Western Red Cedar.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Mass Timber Construction Opportunities For<br />

Western Red Cedar. Or, How Wood Begets Wood.<br />

By Brad Kirkbride, Managing Director, Western Red Cedar Lumber Association<br />

Timber <strong>Products</strong> Hosts Guests At IWF<br />

Photos By Terry Miller<br />

Wanuskewin, located outside Saskatoon, Saskatchewan, is a mass timber and Glulam beam<br />

structure clad in vertical WRC wall panels.<br />

Architect: aodbt architecture + interior design<br />

Photo: Garrett Kendel from King Rose Visuals<br />

<strong>The</strong> Great Dharma Chan Monastery in Boulder, CO. (Also called the Chung Tai<br />

Zen Center) finished in Western Red Cedar.<br />

Architect: Sopher Sparn Architects<br />

Photo: Brad Nicol Photography<br />

Nazli Nazaruddin, Clarke Veneers and Plywood, Jackson, MS; Katharina Schneider,<br />

11Foundry LLC, Vienna, Austria; Kevin Smith, Timber <strong>Products</strong> Company, Springfield,<br />

OR; (front, center) Rachel Milligan, Associated Hardwoods Inc., Tampa, FL; Dave Lupsha,<br />

Associated Hardwoods Inc., Granite Falls, NC; Jason Harper, Clarke Veneers and<br />

Plywood, Madison, MS; and Ian Clarke, Clarke Veneers and Plywood, Jackson, MS<br />

Tom Gennarelli, Timber <strong>Products</strong> Company, Springfield, OR; Anna McCann, Merritt Machinery<br />

LLC, Lockport, NY; Mark Avery, Timber <strong>Products</strong> Company; and Matthew Avery,<br />

MJB Wood Group LLC, Dallas, TX<br />

Additional Photos on page 26<br />

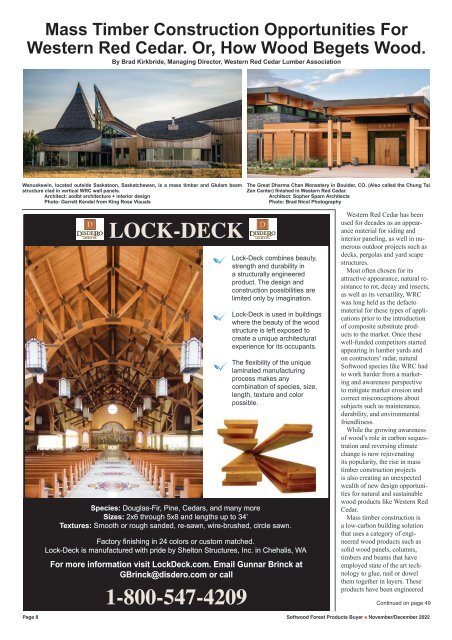

LOCK-DECK<br />

Lock-Deck combines beauty,<br />

strength and durability in<br />

a structurally engineered<br />

product. <strong>The</strong> design and<br />

construction possibilities are<br />

limited only by imagination.<br />

Lock-Deck is used in buildings<br />

where the beauty of the wood<br />

structure is left exposed to<br />

create a unique architectural<br />

experience for its occupants.<br />

<strong>The</strong> flexibility of the unique<br />

laminated manufacturing<br />

process makes any<br />

combination of species, size,<br />

length, texture and color<br />

possible.<br />

Species: Douglas-Fir, Pine, Cedars, and many more<br />

Sizes: 2x6 through 5x8 and lengths up to 34’<br />

Textures: Smooth or rough sanded, re-sawn, wire-brushed, circle sawn.<br />

Factory finishing in 24 colors or custom matched.<br />

Lock-Deck is manufactured with pride by Shelton Structures, Inc. in Chehalis, WA<br />

For more information visit LockDeck.com. Email Gunnar Brinck at<br />

GBrinck@disdero.com or call<br />

1-800-547-4209<br />

Western Red Cedar has been<br />

used for decades as an appearance<br />

material for siding and<br />

interior paneling, as well in numerous<br />

outdoor projects such as<br />

decks, pergolas and yard scape<br />

structures.<br />

Most often chosen for its<br />

attractive appearance, natural resistance<br />

to rot, decay and insects,<br />

as well as its versatility, WRC<br />

was long held as the defacto<br />

material for these types of applications<br />

prior to the introduction<br />

of composite substitute products<br />

to the market. Once these<br />

well-funded competitors started<br />

appearing in lumber yards and<br />

on contractors’ radar, natural<br />

<strong>Softwood</strong> species like WRC had<br />

to work harder from a marketing<br />

and awareness perspective<br />

to mitigate market erosion and<br />

correct misconceptions about<br />

subjects such as maintenance,<br />

durability, and environmental<br />

friendliness.<br />

While the growing awareness<br />

of wood’s role in carbon sequestration<br />

and reversing climate<br />

change is now rejuvenating<br />

its popularity, the rise in mass<br />

timber construction projects<br />

is also creating an unexpected<br />

wealth of new design opportunities<br />

for natural and sustainable<br />

wood products like Western Red<br />

Cedar.<br />

Mass timber construction is<br />

a low-carbon building solution<br />

that uses a category of engineered<br />

wood products such as<br />

solid wood panels, columns,<br />

timbers and beams that have<br />

employed state of the art technology<br />

to glue, nail or dowel<br />

them together in layers. <strong>The</strong>se<br />

products have been engineered<br />

Continued on page 49<br />

Atlanta, GA–Timber <strong>Products</strong><br />

of Springfield, OR welcomed<br />

clients and business associates<br />

to a reception held here at <strong>The</strong><br />

Aquarium.<br />

Approximately 75 people were<br />

in attendance to enjoy an open<br />

bar and heavy hors d'oevres.<br />

Founded in 1918, Timber<br />

<strong>Products</strong> offers a variety of premium<br />

northern hardwood lumber<br />

and <strong>Softwood</strong> plywood products<br />

to cover a broad array of project<br />

needs. <strong>The</strong> company offers everything<br />

from marine panels to<br />

underlayment, sheathing, custom<br />

cuts and more. <strong>The</strong> company<br />

is committed to environmental<br />

sustainability and offers a fully<br />

integrated approach to manufacturing<br />

with multiple manufacturing<br />

facilities, an import division,<br />

and a nationwide logistics and<br />

transportation division, according<br />

to its website.<br />

Learn more at www.timberproducts.com.<br />

READ EVERY<br />

ISSUE ONLINE<br />

softwoodbuyer.com<br />

Can You Find Your Car in this Picture?<br />

Rail cars awaiting classification in a railyard somewhere in the Midwest…<br />

Even when a car’s location is known, there’s no telling when it will deliver.<br />

Or whether what’s on it will still be what you need when it arrives weeks after you ordered it.<br />

And heaven forbid the market should fall off a cliff while your car is taking its sweet time.<br />

IDAHO TIMBER ships trucks FAST, direct from our 8 regional mills for delivery<br />

within 1-2 days, dramatically reducing your stress, costs and risks:<br />

g<br />

You get the right product right when you need it, keeping you in stock and in balance.<br />

g<br />

Inventory and capital needs drop by 80% and truck volume can be received and sold<br />

before the invoice is even due, so your cashflow soars while carrying costs shrink.<br />

g<br />

Truckloads sell 4x faster than carloads, quadrupling your turns and GMROI.<br />

g<br />

Fast delivery and quick turns virtually eliminate exposure to loss in a falling market.<br />

Stop the train pain. Get trucks FAST from IDAHO TIMBER.<br />

800-654-8110<br />

Page 8 <strong>Softwood</strong> <strong>Forest</strong> <strong>Products</strong> <strong>Buyer</strong> • <strong>November</strong>/<strong>December</strong> <strong>2022</strong> <strong>Softwood</strong> <strong>Forest</strong> <strong>Products</strong> <strong>Buyer</strong> • <strong>November</strong>/<strong>December</strong> <strong>2022</strong> Page 9