Features: - Tanker Operator

Features: - Tanker Operator

Features: - Tanker Operator

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Celebrating 50 years of service<br />

Voyage Planning Regulatory Advisory Reports and Logs<br />

We are pleased to introduce the<br />

Glosten Ballast Management System<br />

Target Release Date: September 2008<br />

• Software solution for environmental compliance<br />

with ballast management regulations. Designed for<br />

fleet consistency and time savings for crew.<br />

• Easy entry of planned ballast uptake, exchange,<br />

treatment and discharge evolutions by port or tank.<br />

• Immediate compliance feedback based on geographic-<br />

based regulatory database.<br />

• Searchable advisory library of world-wide ballast<br />

management regulations.<br />

• Automated generation of mandatory reports and logs<br />

(e.g. IMO, USCG, Saint Lawrence Seaway, Australia,<br />

California).<br />

• Under Development – Target Release September 2008.<br />

• Contact gbms@glosten.com for more information.<br />

INDUSTRY - FOCUS ON GERMANY<br />

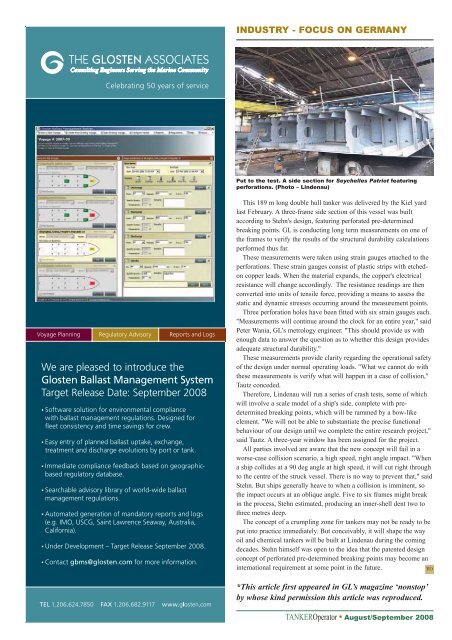

Put to the test. A side section for Seychelles Patriot featuring<br />

perforations. (Photo – Lindenau)<br />

This 189 m long double hull tanker was delivered by the Kiel yard<br />

last February. A three-frame side section of this vessel was built<br />

according to Stehn's design, featuring perforated pre-determined<br />

breaking points. GL is conducting long term measurements on one of<br />

the frames to verify the results of the structural durability calculations<br />

performed thus far.<br />

These measurements were taken using strain gauges attached to the<br />

perforations. These strain gauges consist of plastic strips with etchedon<br />

copper leads. When the material expands, the copper's electrical<br />

resistance will change accordingly. The resistance readings are then<br />

converted into units of tensile force, providing a means to assess the<br />

static and dynamic stresses occurring around the measurement points.<br />

Three perforation holes have been fitted with six strain gauges each.<br />

"Measurements will continue around the clock for an entire year," said<br />

Peter Wania, GL's metrology engineer. "This should provide us with<br />

enough data to answer the question as to whether this design provides<br />

adequate structural durability."<br />

These measurements provide clarity regarding the operational safety<br />

of the design under normal operating loads. "What we cannot do with<br />

these measurements is verify what will happen in a case of collision,"<br />

Tautz conceded.<br />

Therefore, Lindenau will run a series of crash tests, some of which<br />

will involve a scale model of a ship's side, complete with predetermined<br />

breaking points, which will be rammed by a bow-like<br />

element. "We will not be able to substantiate the precise functional<br />

behaviour of our design until we complete the entire research project,"<br />

said Tautz. A three-year window has been assigned for the project.<br />

All parties involved are aware that the new concept will fail in a<br />

worse-case collision scenario, a high speed, right angle impact. "When<br />

a ship collides at a 90 deg angle at high speed, it will cut right through<br />

to the centre of the struck vessel. There is no way to prevent that," said<br />

Stehn. But ships generally heave to when a collision is imminent, so<br />

the impact occurs at an oblique angle. Five to six frames might break<br />

in the process, Stehn estimated, producing an inner-shell dent two to<br />

three metres deep.<br />

The concept of a crumpling zone for tankers may not be ready to be<br />

put into practice immediately. But conceivably, it will shape the way<br />

oil and chemical tankers will be built at Lindenau during the coming<br />

decades. Stehn himself was open to the idea that the patented design<br />

concept of perforated pre-determined breaking points may become an<br />

international requirement at some point in the future.<br />

*This article first appeared in GL’s magazine ‘nonstop’<br />

by whose kind permission this article was reproduced.<br />

TO<br />

TANKER<strong>Operator</strong> � August/September 2008