cases from tanzania - Sustainet

cases from tanzania - Sustainet

cases from tanzania - Sustainet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

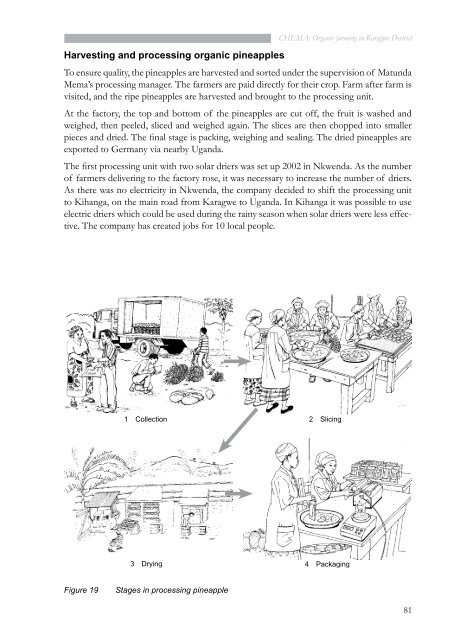

harvesting and processing organic pineapples<br />

CHEMA: Organic farming in Karagwe District<br />

To ensure quality, the pineapples are harvested and sorted under the supervision of Matunda<br />

Mema’s processing manager. The farmers are paid directly for their crop. Farm after farm is<br />

visited, and the ripe pineapples are harvested and brought to the processing unit.<br />

At the factory, the top and bottom of the pineapples are cut off, the fruit is washed and<br />

weighed, then peeled, sliced and weighed again. The slices are then chopped into smaller<br />

pieces and dried. The final stage is packing, weighing and sealing. The dried pineapples are<br />

exported to Germany via nearby Uganda.<br />

The first processing unit with two solar driers was set up 2002 in Nkwenda. As the number<br />

of farmers delivering to the factory rose, it was necessary to increase the number of driers.<br />

As there was no electricity in Nkwenda, the company decided to shift the processing unit<br />

to Kihanga, on the main road <strong>from</strong> Karagwe to Uganda. In Kihanga it was possible to use<br />

electric driers which could be used during the rainy season when solar driers were less effective.<br />

The company has created jobs for 10 local people.<br />

1 Collection<br />

3 Drying<br />

Figure 19 Stages in processing pineapple<br />

2 Slicing<br />

4 Packaging<br />

81